Polyurethane rubber composition and preparation process thereof

A technology of polyurethane rubber and composition, applied in the field of degradable polyurethane rubber composition, can solve problems such as non-degradability, and achieve the effects of good compatibility, improved processing performance, and increased fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

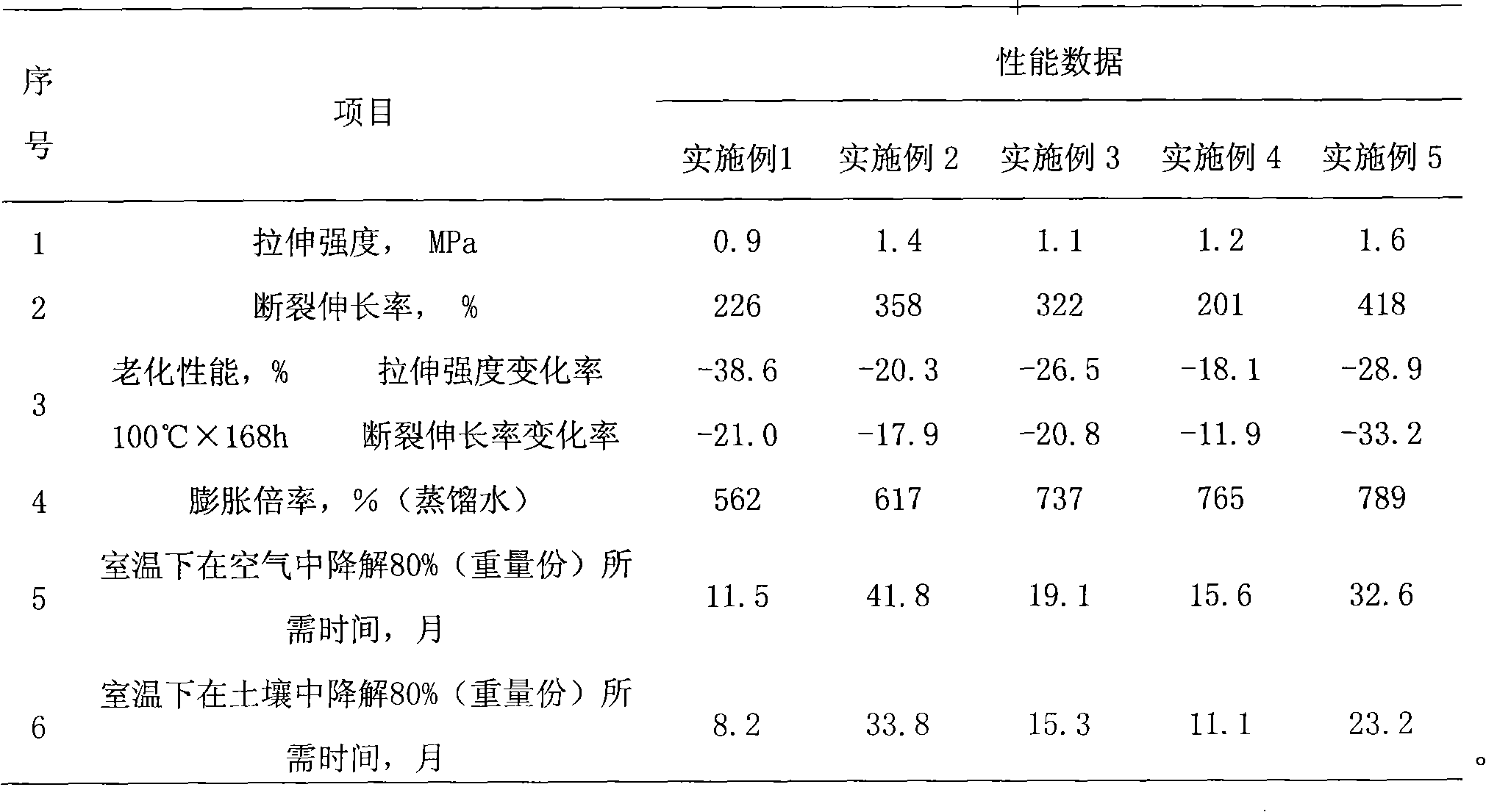

Examples

Embodiment 1

[0052] A) First, 20 parts by weight of ammonium persulfate are dissolved in 25 parts by weight of deionized water, added into mung bean starch of 100 parts by weight, and stirred evenly to form starch mixture H 1 ;

[0053] B) The polyurethane rubber AU28 of 100 parts by weight was masticated on the open mill for 3 minutes, and 25 parts of pre-prepared starch and ammonium persulfate and deionized water mixture H were added. 1 , after mixing for 1 minute, add 1 part of sodium sulfite by weight, after mixing for 5 minutes, add 0.8 parts of stearic acid and 6 parts of zinc oxide, and mix for 1 minute, add 35 parts by weight Ammonium phosphate, after mixing for 2 minutes, add 15 parts by weight of dioctyl phthalate and 4 parts of bisphenol A epoxy resin E-44, and after mixing for 3 minutes, add 20 parts by weight XH-10 type starch grafted acrylic resin, parts by weight are 6 parts of potassium bicarbonate and 3 parts of azobisisobutyronitrile, after mixing for 2 minutes, add 5 pa...

Embodiment 2

[0057] A) At first, 6 parts by weight of ammonium persulfate are dissolved in 11 parts by weight of deionized water, added to 100 parts by weight of wheat starch, stirred evenly, and starch mixture H is formed 2 ;

[0058] B) The polyurethane rubber EU26 that is 100 parts by weight is masticated on the internal mixer for 2 minutes, and 12 parts of pre-prepared starch, ammonium persulfate and deionized water mixture H are added 2 , after mixing for 1 minute, adding parts by weight is 0.6 part of potassium sulfite, after mixing for 6 minutes, adding parts by weight is 1 part of stearic acid and zinc oxide of 8 parts, after mixing for 1 minute, adding parts by weight is 1.5 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine organic complex and 1 part of 2-mercaptobenzimidazole, after mixing for 1 minute, add parts by weight It is 48 parts of granular ordinary calcium superphosphate. After mixing for 3 minutes, add 10 parts by weight of dioctyl sebacate and 7 parts of bi...

Embodiment 3

[0062] A) at first the ammonium persulfate that is 8 parts by weight is dissolved in the deionized water that is 15 parts by weight, joins in the potato starch that is 100 parts by weight, stirs, forms starch mixture H 3 ;

[0063] B) The polyurethane rubber EU26 that is 50 parts by weight is masticated on the open mill for 2 minutes, and then the polyurethane rubber AU 28 that is 50 parts by weight is added to the open mill and mixed with polyurethane rubber Eelastothane 640 for 3 minutes, and 35 parts are added Parts pre-prepared mixture of starch and sodium persulfate and deionized water H 3 , after mixing for 1 minute, adding parts by weight was 0.7 part of potassium sulfite, after mixing for 8 minutes, adding parts by weight were 0.9 parts of stearic acid and zinc oxide of 5.6 parts, after mixing for 1 minute, adding parts by weight of 2.4 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine organic complex, after mixing for 0.5 minutes, add 40 parts by weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com