Method for preparing high-efficiency antioxidant potato protein antioxidant peptide

A potato protein and antioxidant technology, applied in the direction of fermentation, to achieve the effect of extending the industrial chain, increasing industrial added value, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

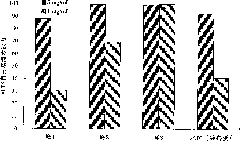

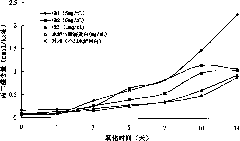

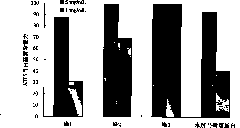

Embodiment 1

[0027] Take 64g of potato protein powder and dissolve it in 1600mL deionized water, adjust the pH of the potato protein solution (4%, w / v) to about 8.0, add 0.64mL of alkaline protease Alcalase, the enzyme activity is 400000u / mL, use Alcalase enzyme at 50 ℃, 600-800r / min stirring and enzymatic hydrolysis for 1h. After the hydrolysis, adjust the pH to 7.0 with 1M NaOH, and inactivate the enzyme at 80°C for 15 minutes. Centrifuge at 5000 g for 25 min to separate the enzymolysis solution, take the supernatant and filter it with a 0.45 μm microfiltration membrane in a microfiltration device to obtain the permeate. The permeated liquid was vacuum concentrated at a vacuum degree of 0.1 MPa and a temperature of 48°C until the solid content was above 50%. Add the concentrated solution to a gel chromatography column filled with Sephadex G15 filler for separation to obtain components with different molecular weight distributions, repeat the sample loading many times, combine the collec...

Embodiment 2

[0029] Take 64g of potato protein powder and dissolve it in 1600mL deionized water, adjust the pH of the potato protein solution (4%, w / v) to about 8.0, add 0.608mL of alkaline protease Alcalase, the enzyme activity is 400000u / mL, use Alcalase enzyme at 48 ℃, 600-800r / min stirring and enzymatic hydrolysis for 1h. After the hydrolysis, adjust the pH to 7.0 with 1M NaOH, and inactivate the enzyme at 80°C for 15 minutes. Centrifuge at 5000 g for 25 min to separate the enzymolysis solution, take the supernatant and filter it with a 0.45 μm microfiltration membrane in a microfiltration device to obtain the permeate. The permeated liquid was vacuum concentrated at a vacuum degree of 0.1 MPa and a temperature of 48°C until the solid content was above 50%. Add the concentrated solution to a gel chromatography column filled with Sephadex G15 filler for separation to obtain components with different molecular weight distributions, repeat the sample loading many times, combine the colle...

Embodiment 3

[0031] Dissolve 64g of potato protein powder in 1600mL of deionized water, adjust the pH of the potato protein solution (4%, w / v) to about 8.0, add 0.672mL of alkaline protease Alcalase, the enzyme activity is 400000u / mL, and use Alcalase enzyme at 52 ℃, 600-800r / min stirring and enzymatic hydrolysis for 1h. After the hydrolysis, adjust the pH to 7.0 with 1M NaOH, and inactivate the enzyme at 80°C for 15 minutes. Centrifuge at 5000 g for 25 min to separate the enzymolysis solution, take the supernatant and filter it with a 0.45 μm microfiltration membrane in a microfiltration device to obtain the permeate. The permeated liquid was vacuum concentrated at a vacuum degree of 0.1 MPa and a temperature of 48°C until the solid content was above 50%. Add the concentrated solution to a gel chromatography column filled with Sephadex G15 filler for separation to obtain components with different molecular weight distributions, repeat the sample loading many times, combine the collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com