Full-hydraulic screw drilling machine

A fully hydraulic and screw technology, applied in the direction of rotary drilling rigs, drill pipes, drill pipes, etc., can solve the problem of insufficient output torque, the lack of special equipment that can meet the requirements of screw pile construction methods, and the equipment can not solve the problems of fixed ratio feed, Stepless adjustment of speed and other issues to achieve the effect of large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

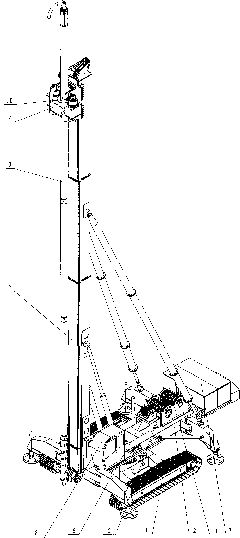

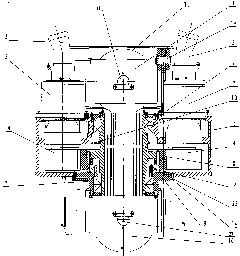

[0041] Attached below Figure 1-9 The full hydraulic screw drilling machine of the present invention is described in detail below.

[0042] as attached figure 1 As shown, the structure of the full hydraulic screw drilling rig of the present invention includes a crawler chassis 1, an upper chassis 2, a mast 3, a power head 4, a main hoist 5, a tool hoist 6, a hydraulic power station 7, an operating room 8, and a drilling system 9. The upper chassis 2 is set on the crawler chassis 1, the mast 3, the main winch 5, the tool winch 6, the hydraulic power station 7, and the operating room 8 are all set on the upper chassis 2, and the power head 4 is slidably set on the mast 3 , the power output end of the power head 4 is connected with the active drill pipe of the drilling tool system 9, and the power input end (hydraulic motor) of the power head 4 and the power input end (hydraulic motor) of the main winch 5 are connected with the hydraulic power station 7 Connection, the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com