Method for manufacturing photovoltaic cell panel

A technology of photovoltaic panels and photovoltaic cells, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as fragile, and achieve the effect of not easy to crack and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]1) The UV curing material used in this embodiment includes: 80wt% polyurethane acrylate, 4wt% 2,2-diethylacetophenone as initiator, 3wt% polyacrylate as leveling agent, 3wt% silicon Ketones as defoamers;

[0042] 2) Apply the above-mentioned UV curable material on the photovoltaic cell string and two glass substrates welded by a plurality of photovoltaic cell sheets;

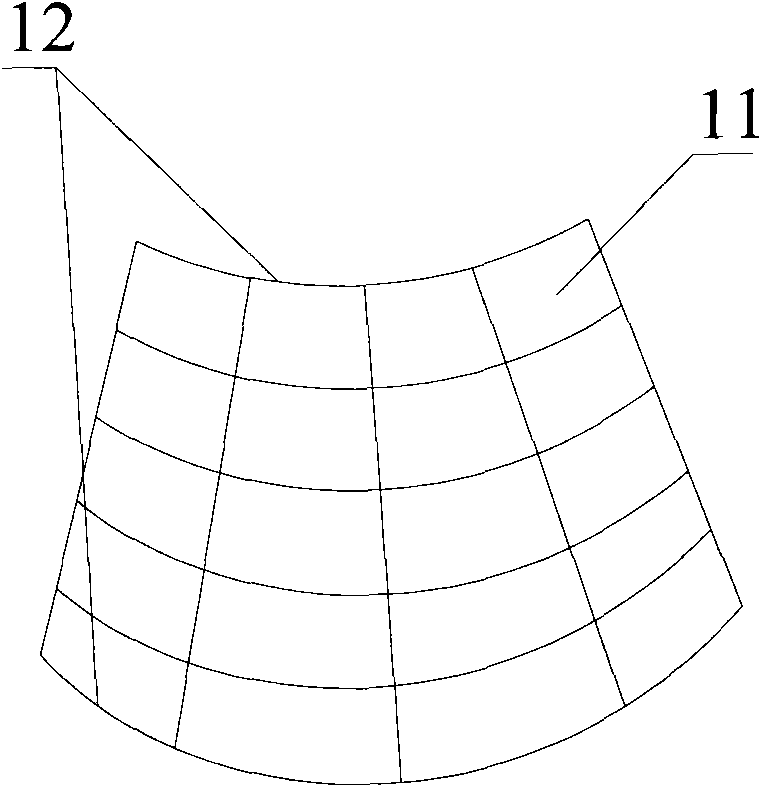

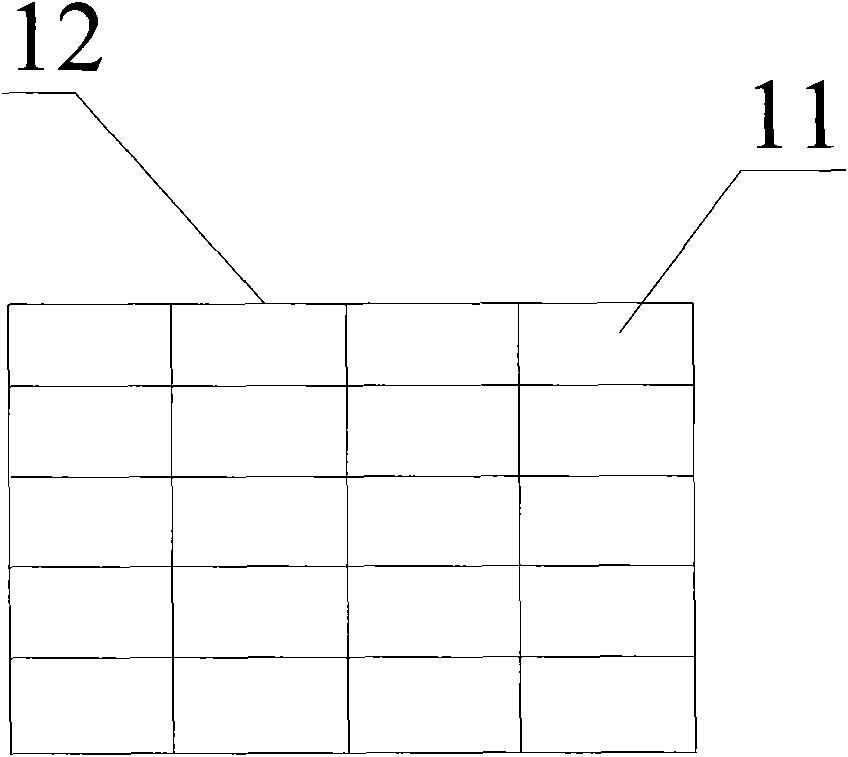

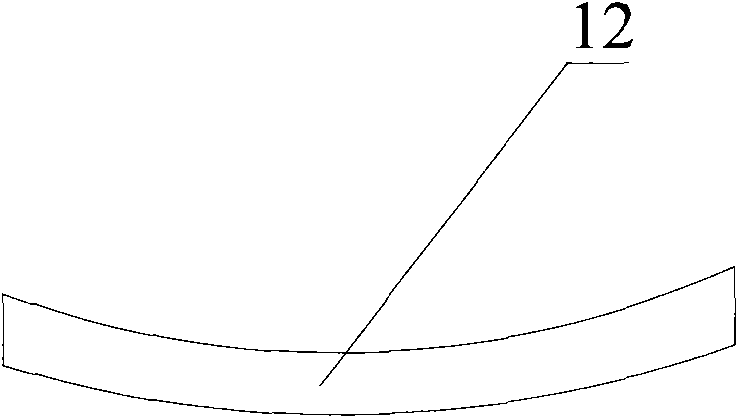

[0043] 3) Assemble the photovoltaic cell string and two substrates into figure 1 The photovoltaic cell assembly shown, the photovoltaic cell assembly is a hyperboloid shape;

[0044] 4) Place the photovoltaic cell assembly in a vacuum at room temperature for vacuum treatment for 30 minutes, with a vacuum degree of 100 Pa;

[0045] 5) Irradiating the photovoltaic cell assembly in the vacuum vessel with 365nm ultraviolet light for 20 minutes to cure the UV curable material to form a photovoltaic cell panel.

Embodiment 2

[0047] 1) The UV curing material used in this embodiment includes: 80wt% polyester acrylate, 3wt% 4-bromoacetophenone as initiator, 2wt% polyacrylate as leveling agent, 3wt% silicone as disinfectant foaming agent;

[0048] 2) Apply the above-mentioned UV curable material on the photovoltaic cell string and two glass substrates welded by a plurality of photovoltaic cell sheets;

[0049] 3) Assemble the photovoltaic cell string and two substrates into figure 1 The photovoltaic cell assembly shown, the photovoltaic cell assembly is a hyperboloid shape;

[0050] 4) Place the photovoltaic cell assembly in a vacuum at room temperature for vacuum treatment for 35 minutes, with a vacuum degree of 100 Pa;

[0051] 5) Irradiating the photovoltaic cell assembly in the vacuum vessel with 365nm ultraviolet light for 20 minutes to cure the UV curable material to form a photovoltaic cell panel.

Embodiment 3

[0053] 1) The UV curing material used in this embodiment includes: 80wt% polyether acrylate, 4wt% 4-allyl acetophenone as initiator, 3wt% polyacrylate as leveling agent, 3wt% silicone as a defoamer;

[0054] 2) Apply the above-mentioned UV curable material on the photovoltaic cell string and two glass substrates welded by a plurality of photovoltaic cell sheets;

[0055] 3) Assemble the photovoltaic cell string and two substrates into figure 1 The photovoltaic cell assembly shown, the photovoltaic cell assembly is a hyperboloid shape;

[0056] 4) Place the photovoltaic cell assembly in a vacuum at room temperature for vacuum treatment for 40 minutes, with a vacuum degree of 100 Pa;

[0057] 5) Irradiating the photovoltaic cell assembly in the vacuum vessel with 365nm ultraviolet light for 20 minutes to cure the UV curable material to form a photovoltaic cell panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com