Phase-change energy accumulation and temperature control device of sealing equipment

A technology of temperature control device and phase change energy storage, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc. It can solve the problems of difficult cooling of internal heating devices, low cooling power, and increased failure rate, etc., to achieve Stable and controllable temperature, large cooling capacity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Semiconductor refrigeration, also known as thermoelectric refrigeration, is based on the Peltier effect discovered by the French scientist Peltier, that is, when a direct current is applied to a loop composed of two different conductors, a temperature difference appears at the connection. This phenomenon is particularly pronounced in semiconductor materials, where it can produce effective cooling capabilities.

[0027] When a phase change material changes from one state to another, it needs to absorb or release heat from the environment to achieve heat storage and release, which can achieve the purpose of temperature control. When a solid state changes to a liquid state, a large amount of heat is absorbed, and when the liquid changes to a solid state, heat is released. At the same time, the phase change process is generally an isothermal or nearly isothermal process. Using the characteristics of phase change materials, it can be used to adjust Controls the temperature o...

Embodiment 2

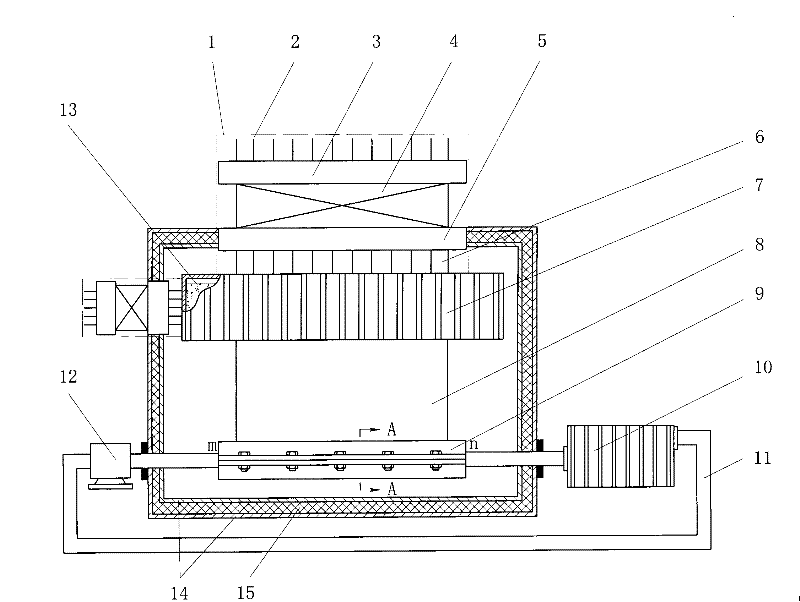

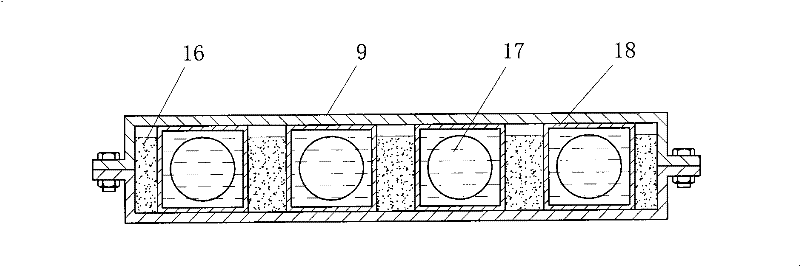

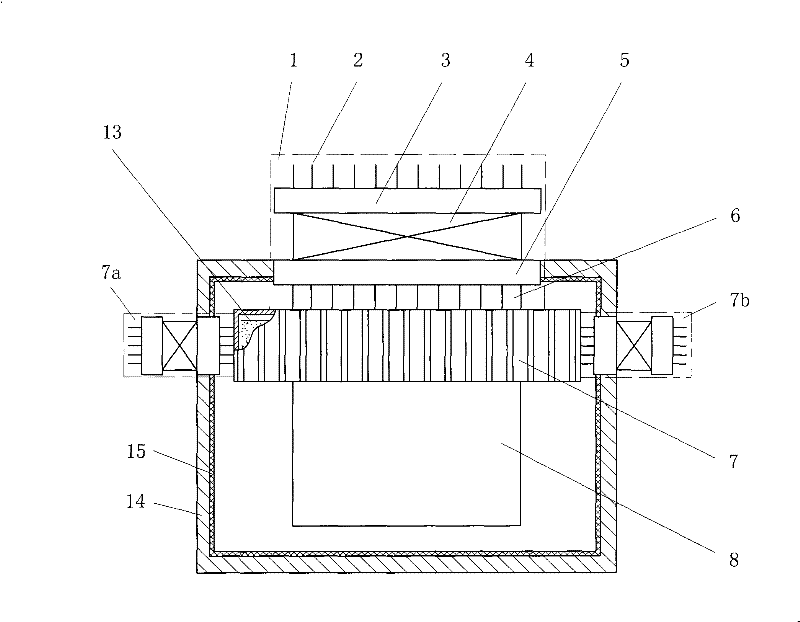

[0032] See image 3 , when the dissipation power of the heating element 8 is not very large, and the volume and weight of the cooling device are strictly required, it can be adopted image 3The temperature control structure shown uses three plate-shaped semiconductor refrigerators 1, 7a, 7b to transfer the heat in the sealed box 14 to the outside of the sealed equipment through the phase change radiator 7 by using the principle of semiconductor refrigeration. For refrigeration, the phase change material in the phase change radiator is basically solid. Similarly, the heat transfer direction of the heat dissipation system of the sealed device is controllable. After the power is cut off, only a small part of the heat from the external environment can enter the inside of the sealed device, relying on the phase change heat absorption of the solid phase change material, which can ensure Temperature control capability inside sealed equipment for harsh environments. It ensures that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com