Welding waste gas treatment device

A waste gas treatment device and waste gas treatment technology, which are applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of insufficient waste gas treatment, insufficient industrial waste gas efficiency, single treatment method, etc. Fully processed and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

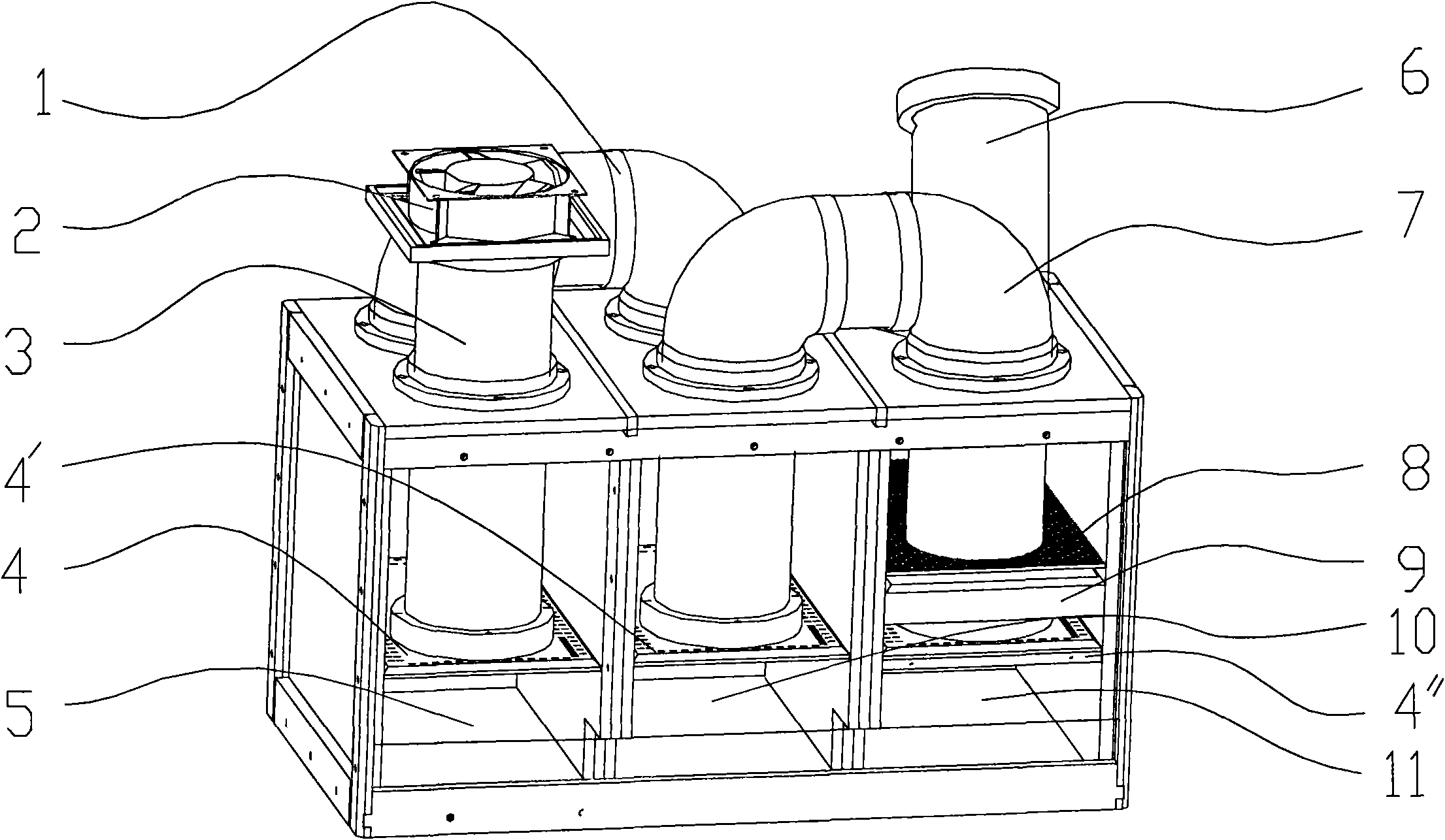

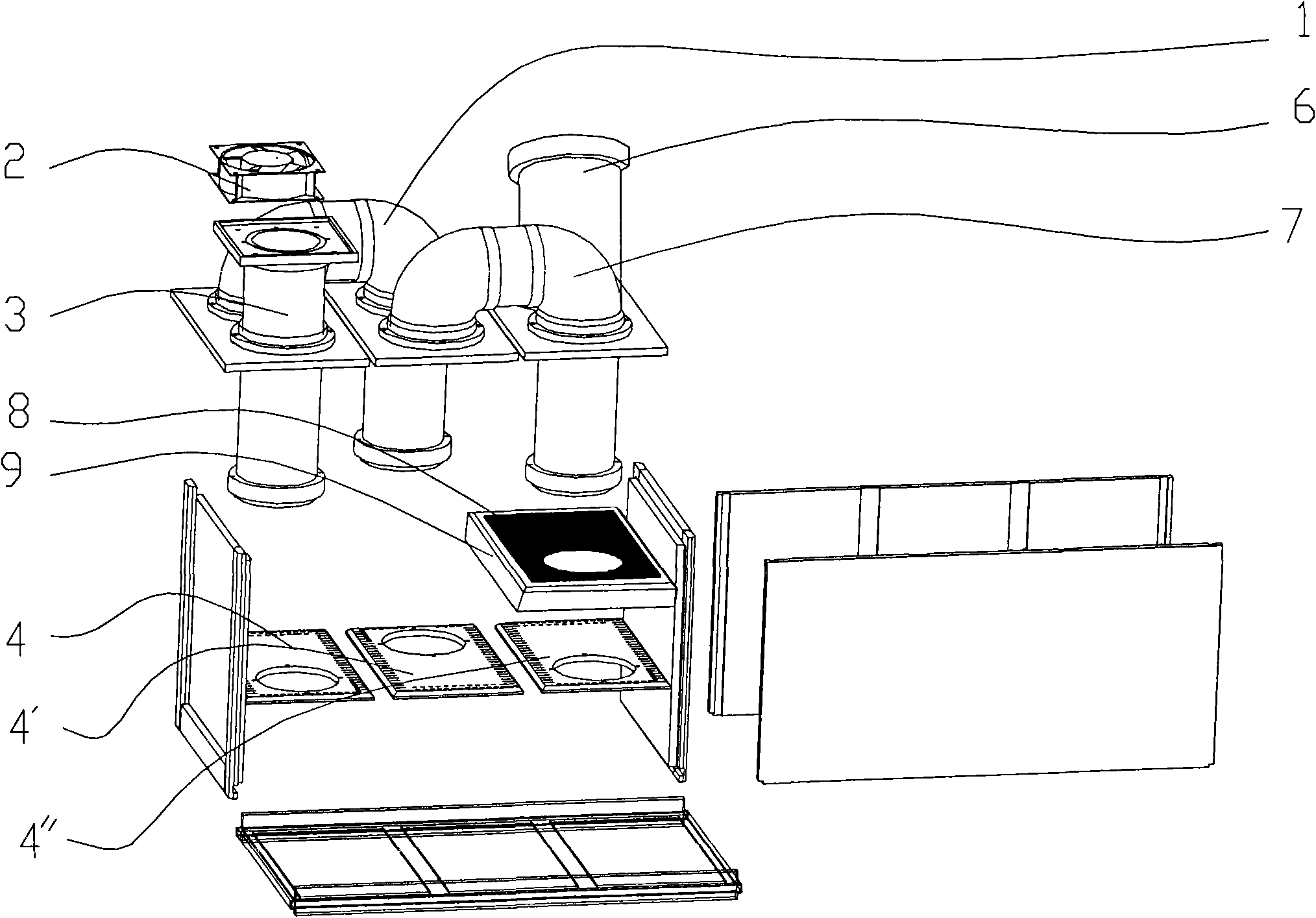

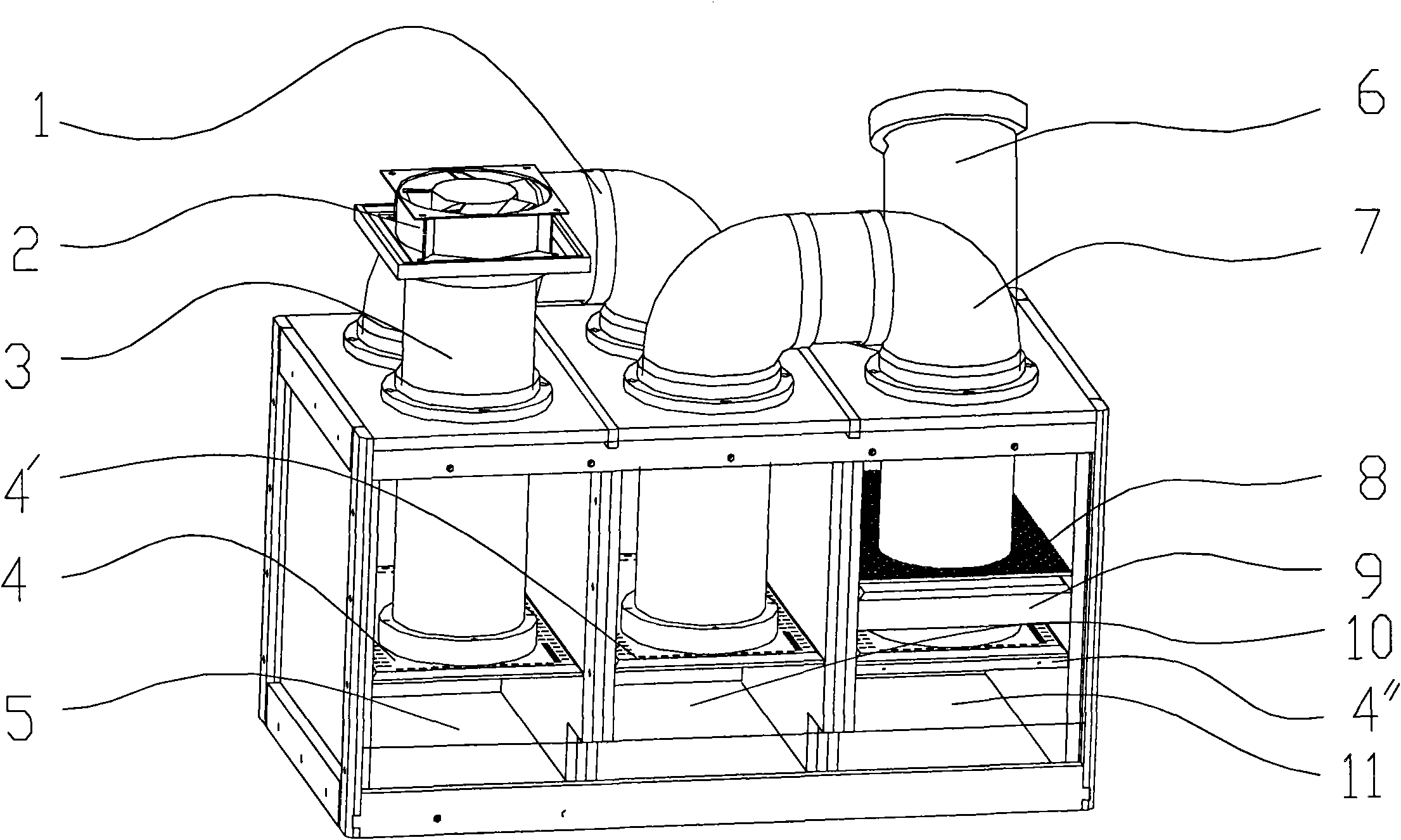

[0017] A welding waste gas treatment device, the device comprises an inlet pipe 3, an outlet pipe 6, and an exhaust gas treatment chamber 5, a primary filter chamber 10, and an exhaust gas adsorption chamber 11 sequentially connected between the inlet pipe 3 and the outlet pipe 6; wherein,

[0018] The exhaust gas treatment chamber 5 and the primary filter chamber 10 are divided into upper and lower layers by the filter partitions 4, 4' with many small holes around them, and the waste gas adsorption chamber 11 is separated by the filter partitions 4" with many small holes around them. The filter cotton 9 arranged in the space above the filter partition 4" is divided into upper, middle and lower layers. The filter cotton 9 is provided with an exhaust gas adsorber 8 composed of molecular sieves, activated carbon and oxidants...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com