Production line of electromagnetic heating corrugated board

A corrugated cardboard and production line technology, applied in the direction of machining/deformation, can solve the problems of short service life, high maintenance cost, polluted air, etc., and achieve the effect of long service life, low maintenance cost and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

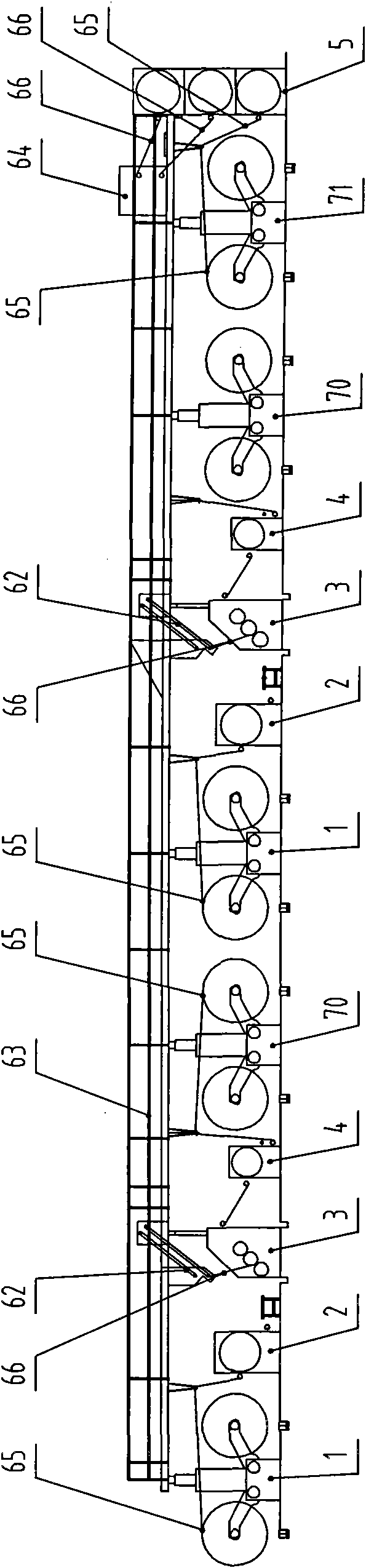

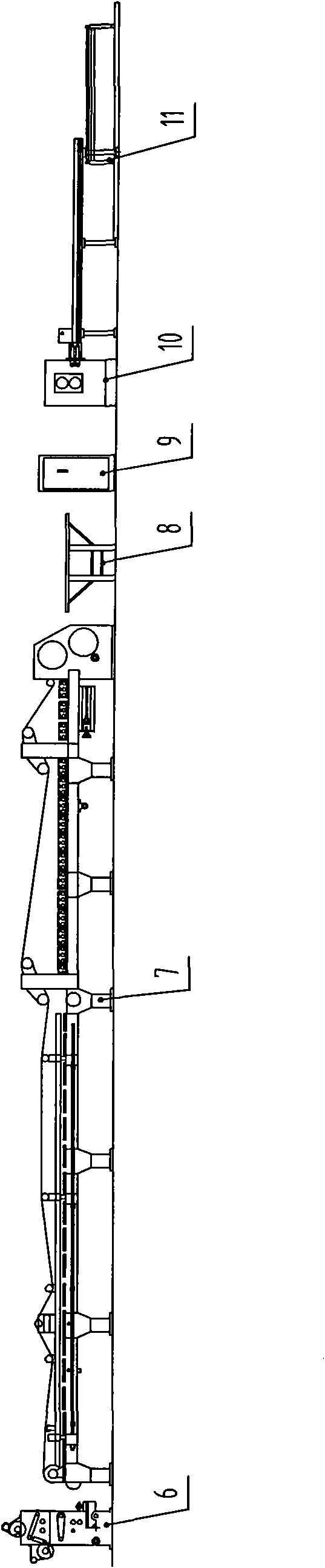

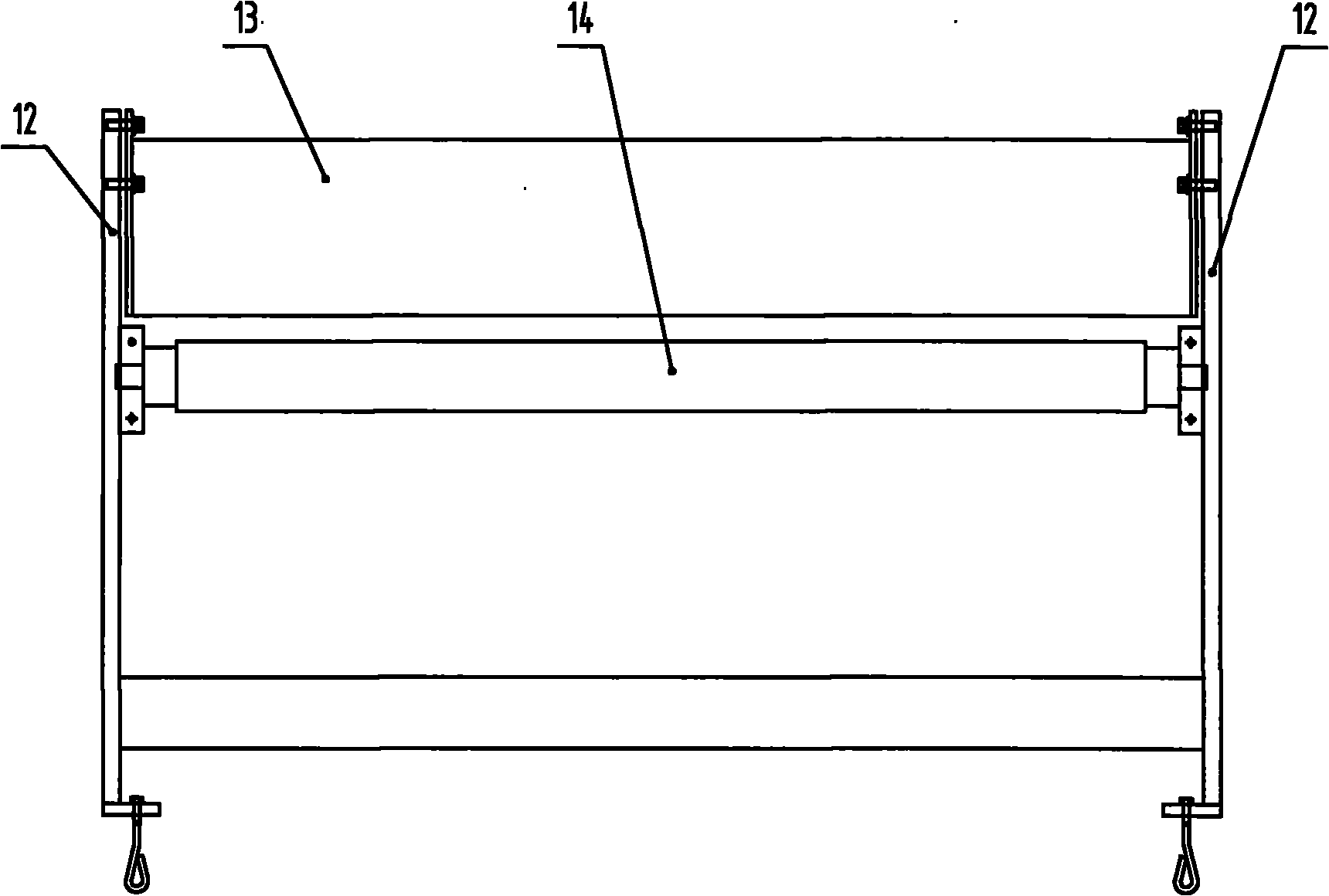

[0026] Such as Figure 1 to Figure 11 As shown, the electromagnetic heating corrugated cardboard production line of the present invention includes two sets of double-layer single-face corrugated cardboard production devices, and each set of double-layer single-face corrugated cardboard production devices includes base paper support 1, face paper preheating Device 2, single-facer 3, core paper preheater 4 and base paper support 70, the upper end of base paper support 1 and base paper support 70 is provided with a paper overpass 63, and a set of double-layer single-faced corrugated cardboard production device at the rear end is provided with a Base paper support 71, overpass suction box 64 is provided on the paper bridge 63 above the base paper support 71, multiple preheaters 5, gluing machine 6, double-sided bonding dryer 7, cooling platform are arranged in sequence behind the base paper support 71 8. Slitting and creasing machine 9, cross cutting machine 10 and conveying and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com