Wear-resistant membrane structure, die and manufacturing method thereof

A technology of thin film structure and manufacturing method, applied in gaseous chemical plating, metal material coating process, layered products, etc., can solve the problems of diamond-like carbon layer peeling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

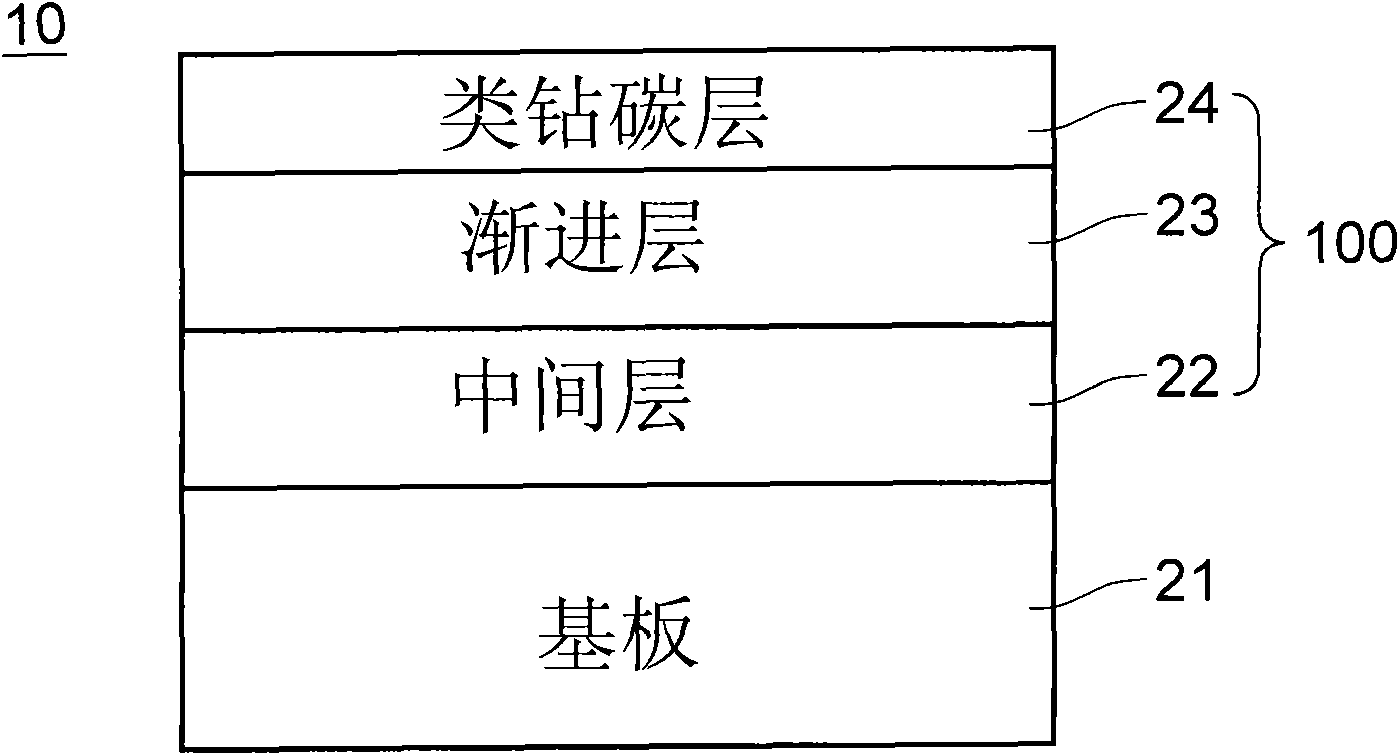

[0030] figure 1 It is a structural schematic diagram of a mold according to an embodiment of the present invention. see figure 1 , the mold 10 includes a wear-resistant film structure 100 and a substrate 21 , and the wear-resistant junction film structure 100 is disposed on the substrate 21 . The wear-resistant thin film structure 100 includes an intermediate layer 22, a progressive layer 23 and a type of diamond carbon layer 24, wherein the intermediate layer 22 is located on the substrate 21, the progressive layer 23 is located on the intermediate layer 22, and the diamond-like carbon layer 24 is located on the progressive layer. layer 23, and the sheet material of the substrate 21 includes any metal or non-metal sheet material.

[0031] In this embodiment, the intermediate layer 22 and the progressive layer 23 are sequentially disposed on the substrate 21 , and the material thereof includes carbon, hydrogen and silicon. However, it should be noted that the silicon conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com