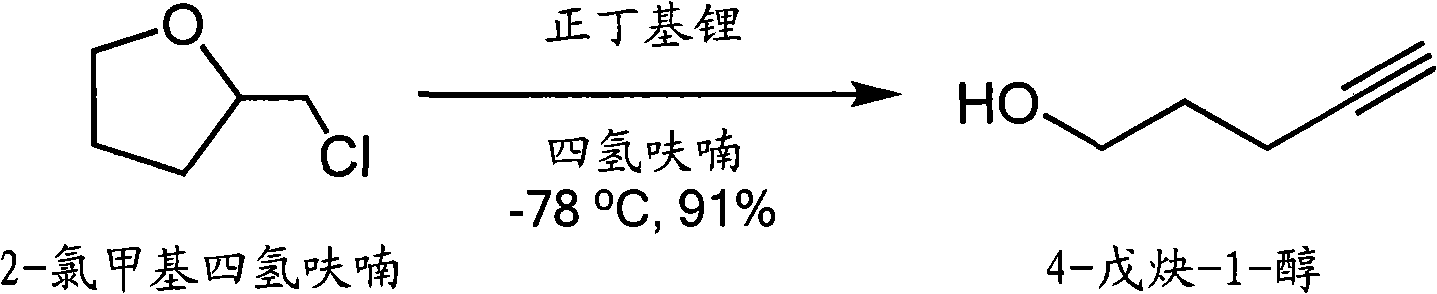

Preparation method of 4-pentyne-1-alcohol

A technology for pentyne and chloromethyl tetrahydrofuran is applied in the field of preparing 4-pentyn-1-ol, and can solve the problems of liquid ammonia easily leaking irritating taste, danger, complicated reaction operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0006] Example 1, the preparation of 4-pentyn-1-alcohol

[0007] Add 200 mL of anhydrous tetrahydrofuran to a dry 500 mL round bottom flask. The flask was cooled to minus 78 degrees Celsius in a dry ice-acetone bath, and then 62.8 mL (157.2 mmol, 2.5 mol / L) of n-butyllithium was added. 2-Chloromethyltetrahydrofuran (6.01 g, 50.7 mmol) was slowly added dropwise to this solution. The reaction temperature was controlled at minus 78 degrees, and the mixture was stirred until the thin layer chromatography showed that the reaction of the raw materials was complete. The reaction was quenched by adding saturated ammonium chloride solution, and the aqueous solution was extracted three times with ether. The organic phase was washed with saturated brine, dried over anhydrous sodium sulfate, and then spin-dried to obtain a crude product. The crude product was separated by column chromatography to obtain 3.9 g of 4-pentyn-1-ol, a colorless transparent liquid, with a yield of 91%.

example 2

[0008] Example two, the preparation of 4-pentyn-1-alcohol

[0009] Add 300 mL of anhydrous tetrahydrofuran to a dry 1000 mL round bottom flask. The flask was cooled to minus 78 degrees Celsius in a dry ice-acetone bath, and then 86.8 mL (217 mmol, 2.5 mol / L) of n-butyllithium was added. 2-Chloromethyltetrahydrofuran (8.3 g, 70 mmol) was slowly added dropwise to this solution. The reaction temperature was controlled at minus 78 degrees, and the mixture was stirred until the thin layer chromatography showed that the reaction of the raw materials was complete. The reaction was quenched by adding saturated ammonium chloride solution, and the aqueous solution was extracted three times with ether. The organic phase was washed with saturated brine, dried over anhydrous sodium sulfate, and then spin-dried to obtain a crude product. The crude product was distilled under reduced pressure to obtain 5.1 g of a colorless and transparent product, 4-pentyn-1-ol, with a yield of 87%.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com