Purification and preparation method of high-purity Daptomycin

A daptomycin, high-purity technology, applied in the field of purification and preparation of high-purity daptomycin, can solve the problems of complicated operation, large product loss, unreported preparation scale and yield, etc., to improve the purification effect, The effect of improving the purification preparation yield and simplifying the production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

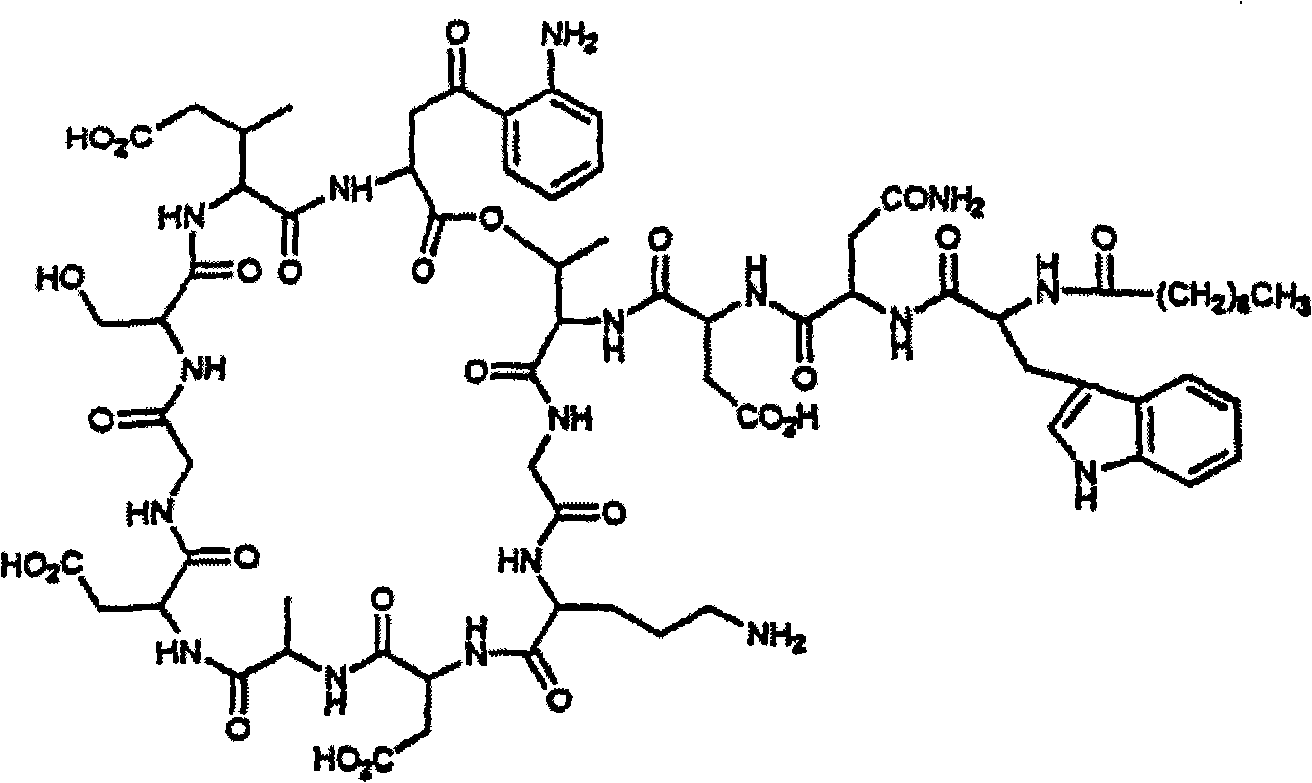

Image

Examples

Embodiment 1

[0018] Buffer: 5% ammonium acetate solution, pH6.0

[0019] 100 g of crude daptomycin (purity 89.22%) was prepared into a solution with a concentration of 10% by buffer, and filtered to obtain a sample solution.

[0020] Install YT-01 reverse-phase silica gel column 8L (particle size: 150-200 mesh), put the sample solution on the column, first wash it with 3 column volumes of buffer solution, and then add 10% acetonitrile to the same buffer solution for analysis. 2 column volumes, then 2 column volumes with 20% acetonitrile, 2 column volumes with 30% acetonitrile, 1 column volume with 40% acetonitrile, about 40% acetonitrile buffer, Purified daptomycin was eluted from reverse phase silica gel. As determined by HPLC, the purity of daptomycin was 98.63%, and the yield was 54.8%.

Embodiment 2

[0022] Buffer: 8% ammonium acetate solution, adjusted to pH 7.0 with acetic acid

[0023] 100 g of crude daptomycin (purity 89.22%) was prepared into a sample solution with a concentration of 8% using buffer.

[0024] YT-01 reverse phase silica gel (particle size 150-200 mesh): 10L

[0025] Elution condition: 10-40% acetonitrile gradient elution

[0026] The HPLC purity of the purified daptomycin was 98.91%, and the yield was 53.2%.

Embodiment 3

[0028] Buffer: 10% ammonium acetate solution, adjusted to pH 8.0 with acetic acid

[0029] 100 g of crude daptomycin (purity 89.22%) was prepared into a sample solution with a concentration of 5% using a buffer.

[0030] YT-01 reverse phase silica gel (particle size 150-200 mesh): 12L

[0031] Elution condition: 10-40% acetonitrile gradient elution

[0032] The HPLC purity of the purified daptomycin was 99.21%, and the yield was 52.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com