Method for producing chlorinated polypropylene with mixed solvent

A chlorinated polypropylene and mixed solvent technology, applied in the field of chlorinated polypropylene production, can solve the problems of high sealing requirements, poor safety, low output of chlorinated polypropylene, etc., and achieves low sealing strength requirements and high production safety. , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

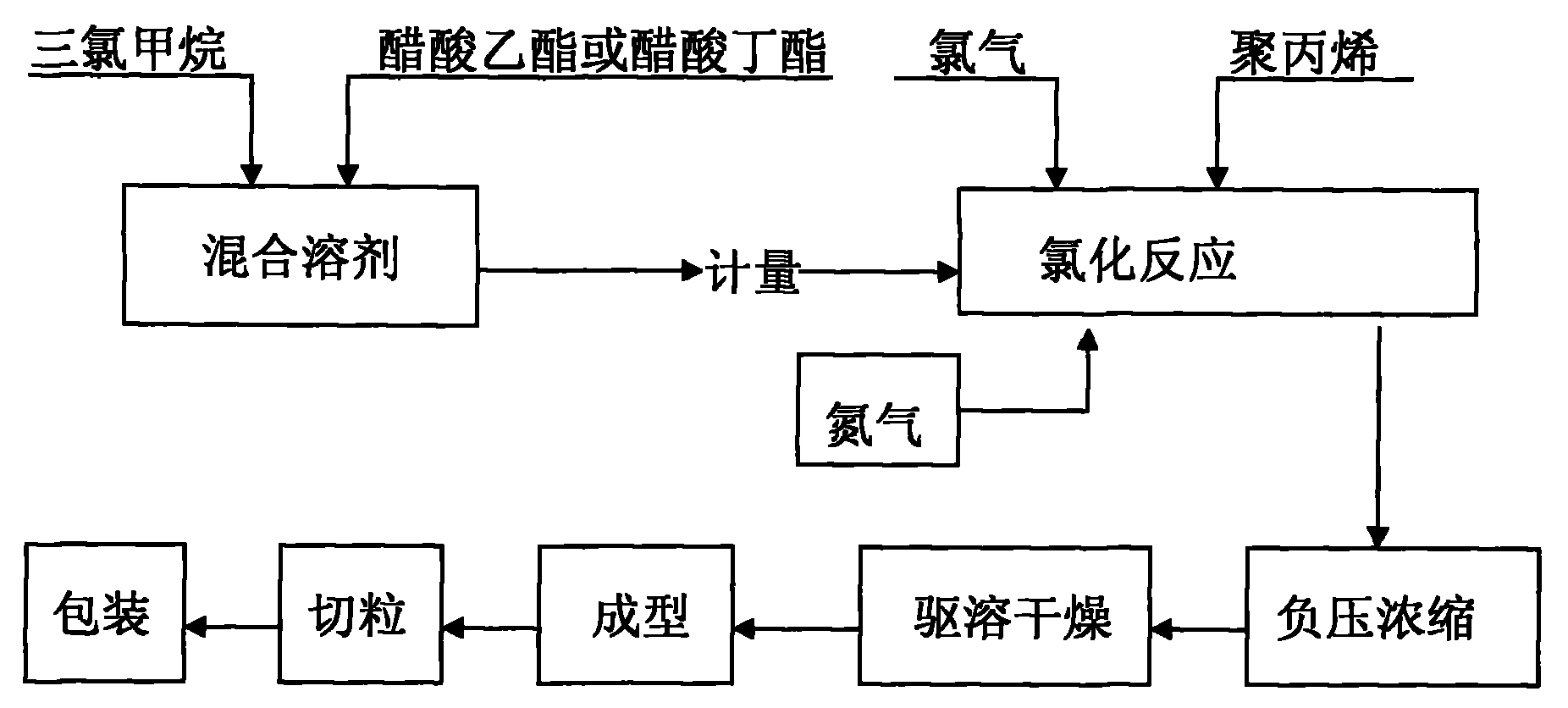

Image

Examples

Embodiment 1

[0027] According to the method steps provided by the production method of the present invention, 6000Kg of mixed solvent containing 20% ethyl acetate and 80% chloroform is added to the reaction kettle, and then 400Kg of polypropylene is added and stirred to raise the temperature to 95°C-100°C, and the pressure strength is 0.15 Under Mpa~0.16Mpa, dissolve for 4 hours. After the dissolution is complete, add 500g of initiator azobisisobutyronitrile to the reaction pot for the first time, and then pass chlorine gas to carry out chlorination reaction; after reacting for 3 hours, stop the chlorine flow and cool down to 90°C±5°C; add 150g of initiator azobisisobutyronitrile to the reaction pot for the second time, and then continue to pass chlorine gas for chlorination reaction; after continuing the reaction for 3 hours, stop the chlorine flow and cool down to 80°C±5 ℃; add an appropriate amount of initiator azobisisobutyronitrile 100g to the reaction pot for the third time, and the...

Embodiment 2

[0029] Add 6000Kg of a mixed solvent containing 5% ethyl acetate and 95% chloroform into the reaction kettle, then add 400Kg of polypropylene, drive and stir to raise the temperature to 100°C-110°C, under the pressure of 0.18Mpa-0.19Mpa, dissolve for 4 hours, After the dissolution is complete, add 500g of initiator azobisisobutyronitrile to the reaction pot for the first time, and then pass chlorine gas for chlorination reaction; after 3 hours of reaction, stop the chlorine flow and cool down to 90°C±5°C; Add an appropriate amount of initiator azobisisobutyronitrile 150g for the second time, and then continue to pass chlorine gas for chlorination reaction; after continuing the reaction for 3 hours, stop the chlorine flow, and lower the temperature to 80°C±5°C; add to the reaction pot for the third time Appropriate amount of initiator azobisisobutyronitrile 100g, and then continue to pass in chlorine gas for chlorination reaction; Concentrate under negative pressure at ℃ to obt...

Embodiment 3

[0031] Add 6000Kg of mixed solvent containing 10% butyl acetate and 90% chloroform into the reaction kettle, then add 400Kg of polypropylene, drive and stir to raise the temperature to 100°C-110°C, under the pressure of 0.16Mpa-0.17Mpa, dissolve for 4 hours, After the dissolution is complete, add an appropriate amount of initiator azobisisobutyronitrile 500g to the reaction pot for the first time, and then pass chlorine gas to carry out the chlorination reaction; Add 150g of initiator azobisisobutyronitrile to the pot for the second time, and then continue to pass chlorine gas for chlorination reaction; after continuing the reaction for 3 hours, stop the chlorine flow, and lower the temperature to 80°C±5°C; add to the reaction pot for the third time 100g of initiator azobisisobutyronitrile, and then continue to pass in chlorine gas for chlorination reaction; after the chlorination reaction, pass in nitrogen gas to replace and absorb the unreacted chlorine gas, and then under ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com