Method for manufacturing polarization-independent grating coupler

A technology of a grating coupler and a manufacturing method, applied in the field of optical coupling, can solve the problems of difference in effective refractive index of devices, low practicability and universality, polarization correlation of devices, etc., and achieve process compatibility, small size, and low polarization correlation loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

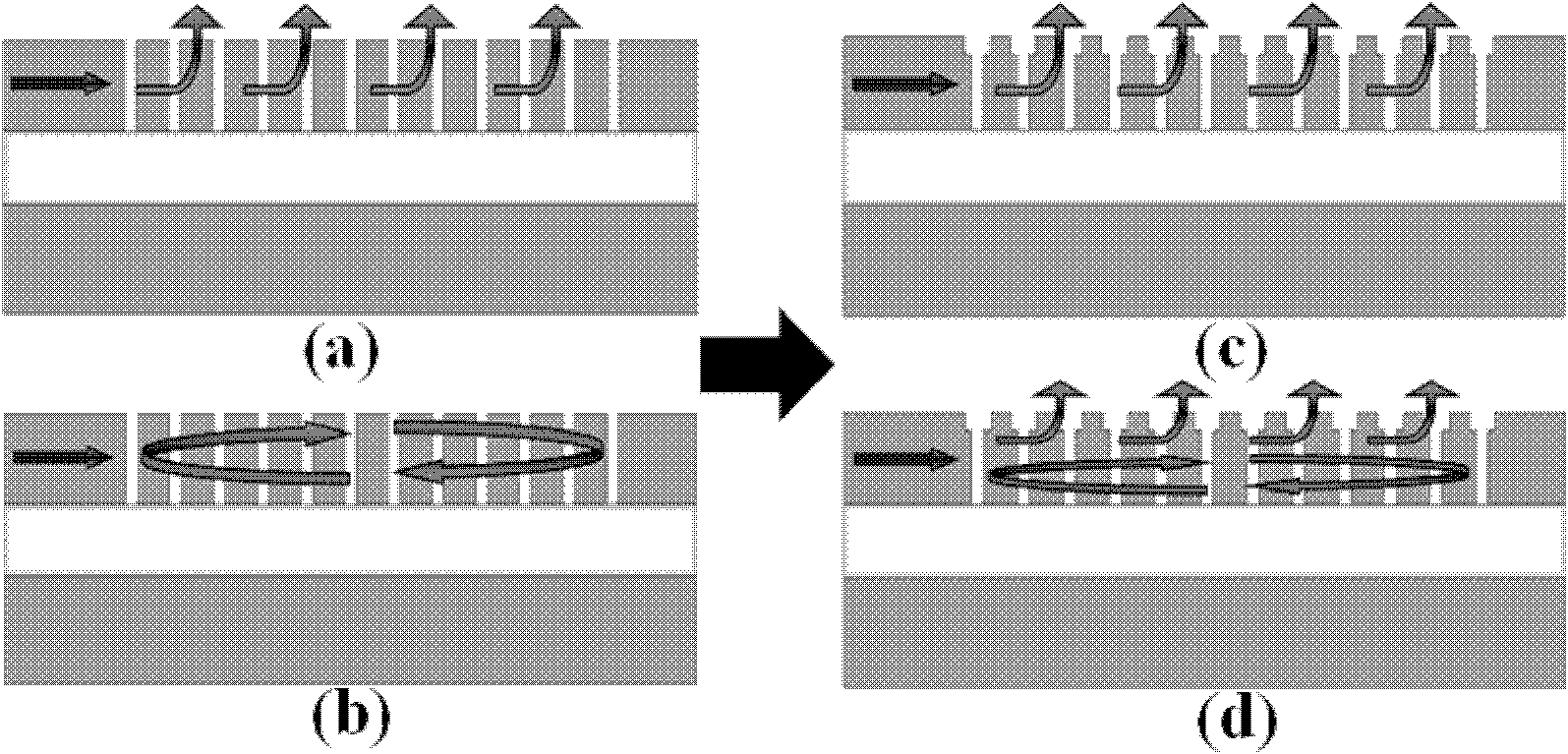

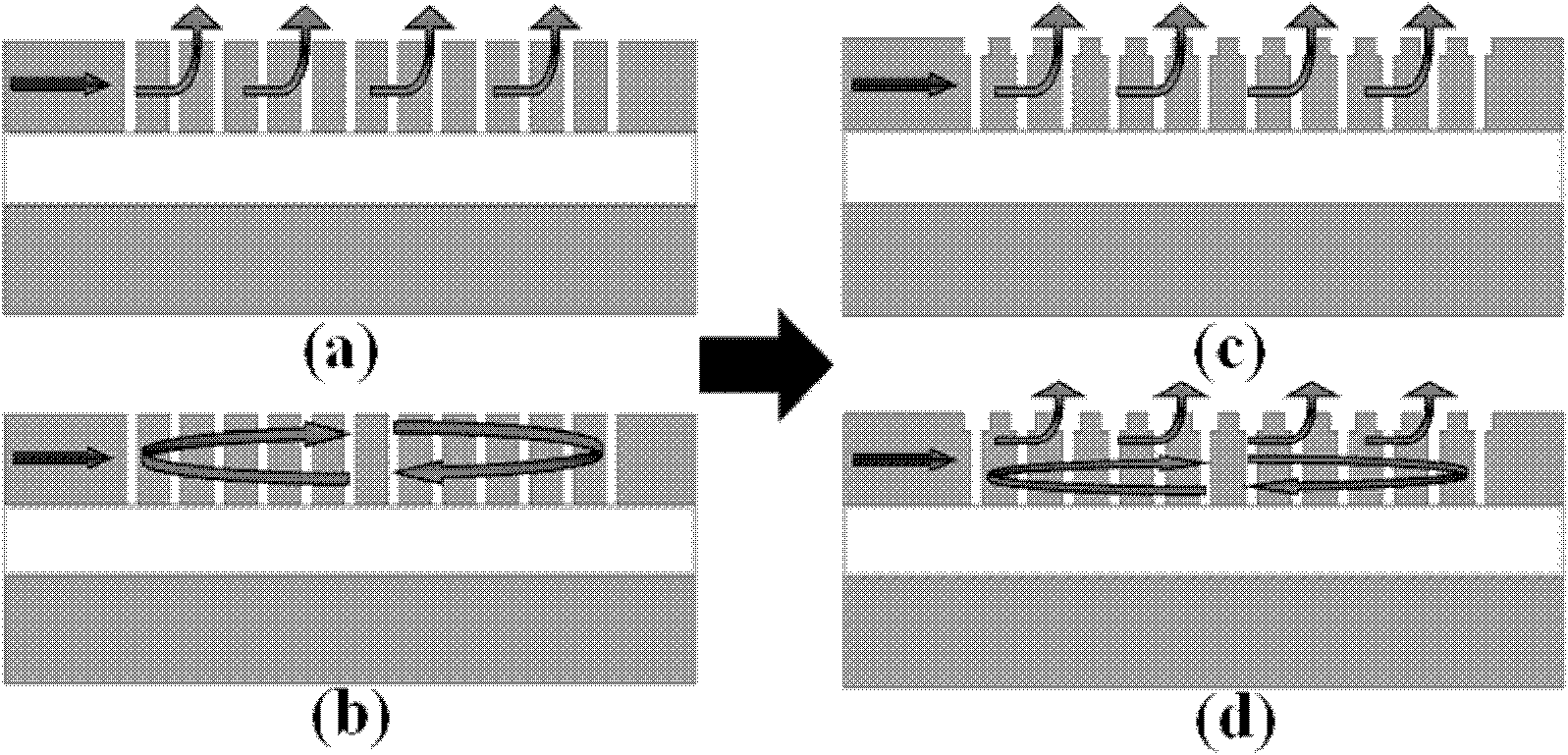

[0017] The purpose of the present invention is to provide a design method for a novel polarization-independent grating coupler with simple structure and easy production. The specific implementation is divided into the following five steps:

[0018] 1. Obtain the period T of the TM mode according to the grating coupling Bragg condition TM ;

[0019] Usually based on the grating Bragg conditions for the TE and TM mode grating couplers of the same wavelength, the grating period will be very different due to the large effective refractive index difference between the two. Here we consider that the TM mode still follows the grating Bragg condition for coupling, then the grating period T TM Should be λ / n eff TM (λ is the coupling wavelength, n eff TM Is the effective refractive index of the TM mode). For the Slot effect of the TM mode, the grooves of the TM grating adopt a vertical Slot groove structure to derive energy to achieve high-efficiency coupling.

[0020] 2. Obtain the period ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com