Method for preparing polycrystalline silicon thin film based on metal induction

A polysilicon thin film, metal-induced technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor performance, many residues, and complex preparation processes, shortening process time, and eliminating alignment plate dislocations effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

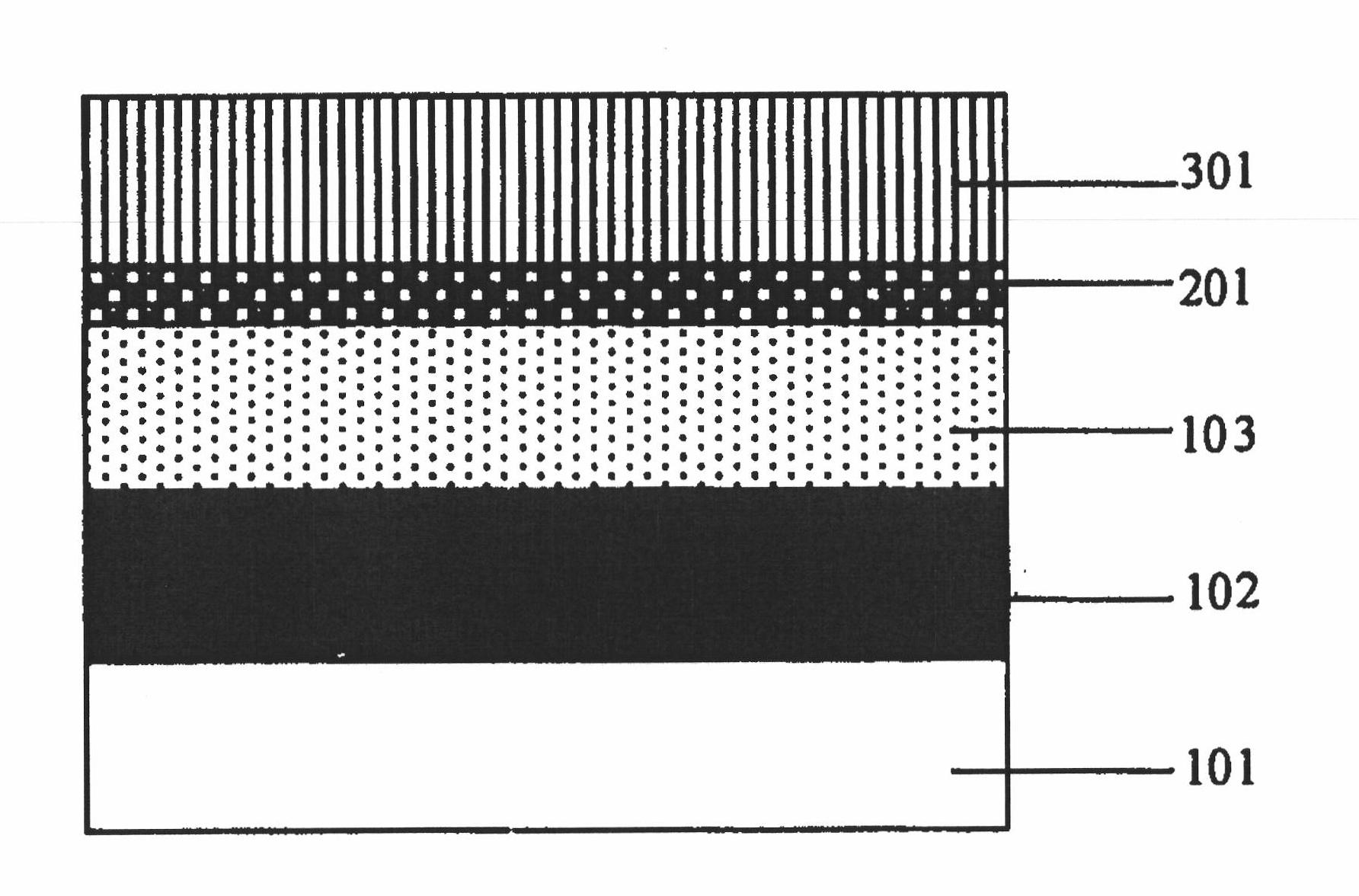

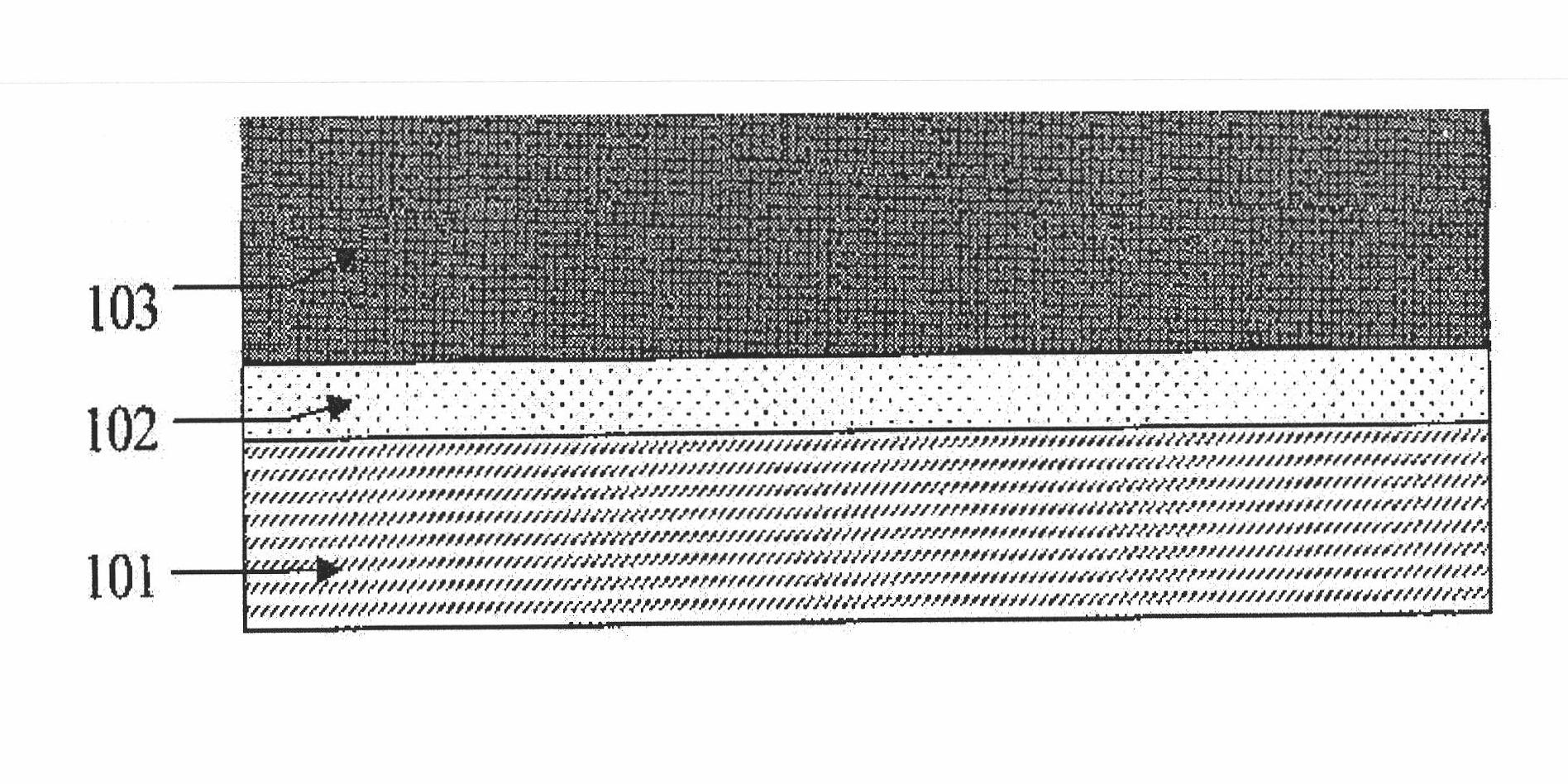

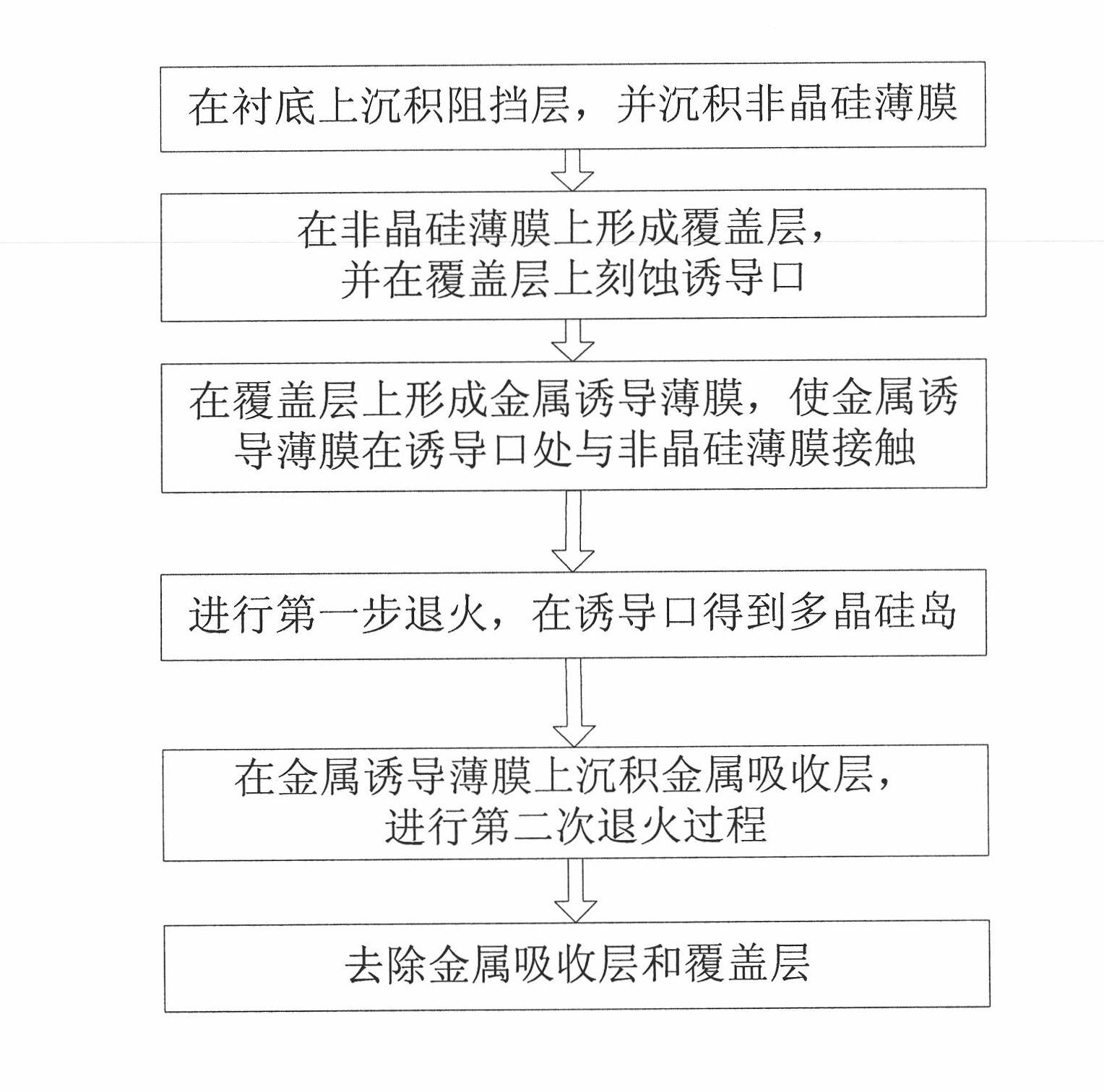

[0041] image 3 A flowchart showing a method for preparing a polysilicon thin film according to an embodiment of the present invention. In general, if image 3As shown, the method includes: depositing a silicon oxide or silicon nitride barrier layer on a glass substrate, and depositing an amorphous silicon film (step 301); forming a layer of silicon oxide or silicon nitride capping layer on the amorphous silicon film , and etch the induction port (step 302) on the cover layer; form a layer of metal induction film on the cover layer, make the metal induction film contact with the amorphous silicon film at the induction port (step 303); carry out the first step Annealing process, polysilicon islands are obtained in the amorphous silicon film below the induction port (step 304); a metal absorption layer is deposited on the metal induction film, and then the second annealing process is performed to form crystallized amorphous with uniform distribution of crystal grains Silicon t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com