Sludge treating system

A sludge treatment and sludge technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as mesh blockage and heat exchange efficiency reduction, achieve effective heat treatment, and simple structure , not easy to reduce the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, one Embodiment of the sludge processing system of this invention is demonstrated in detail using drawing.

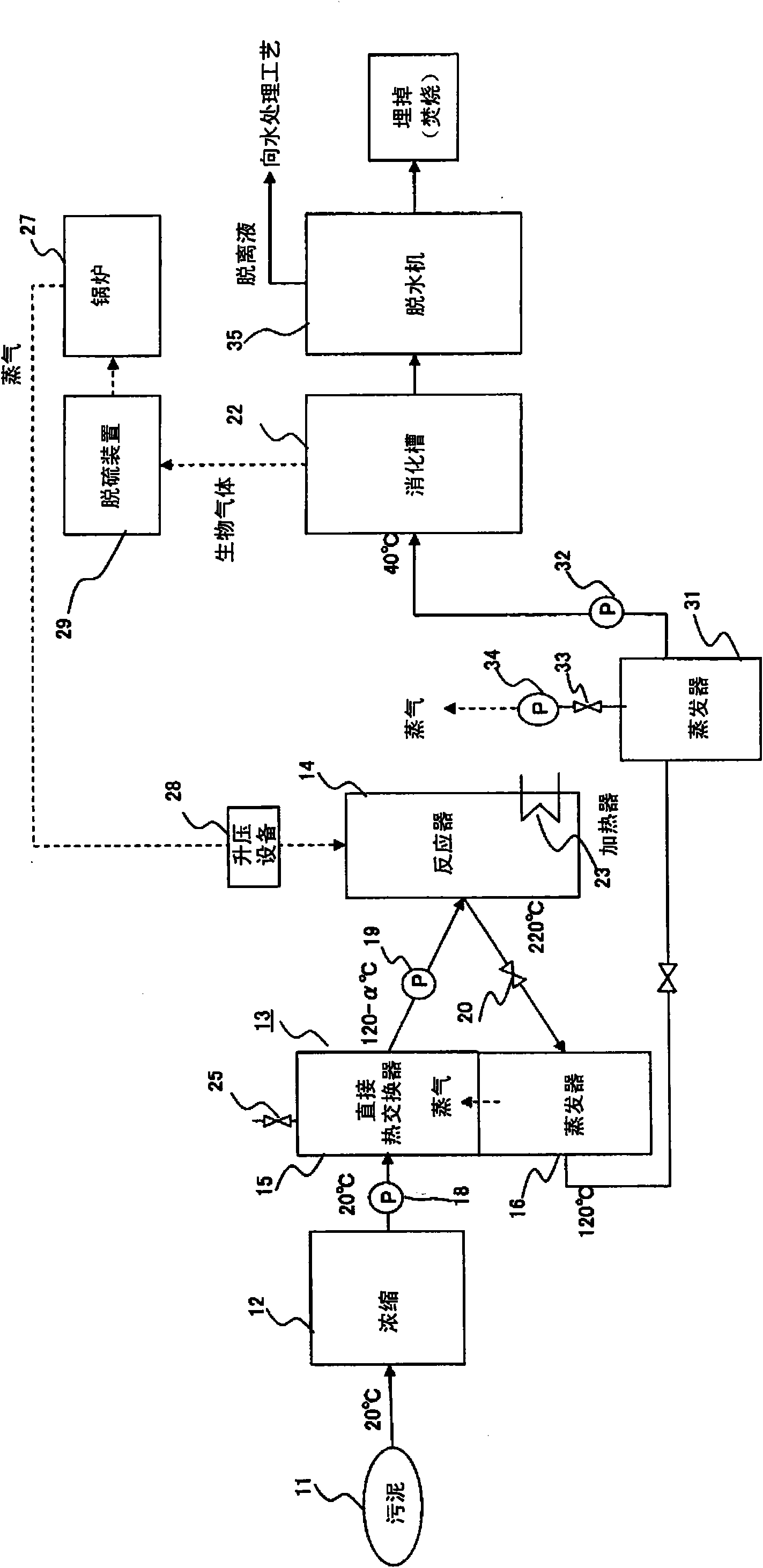

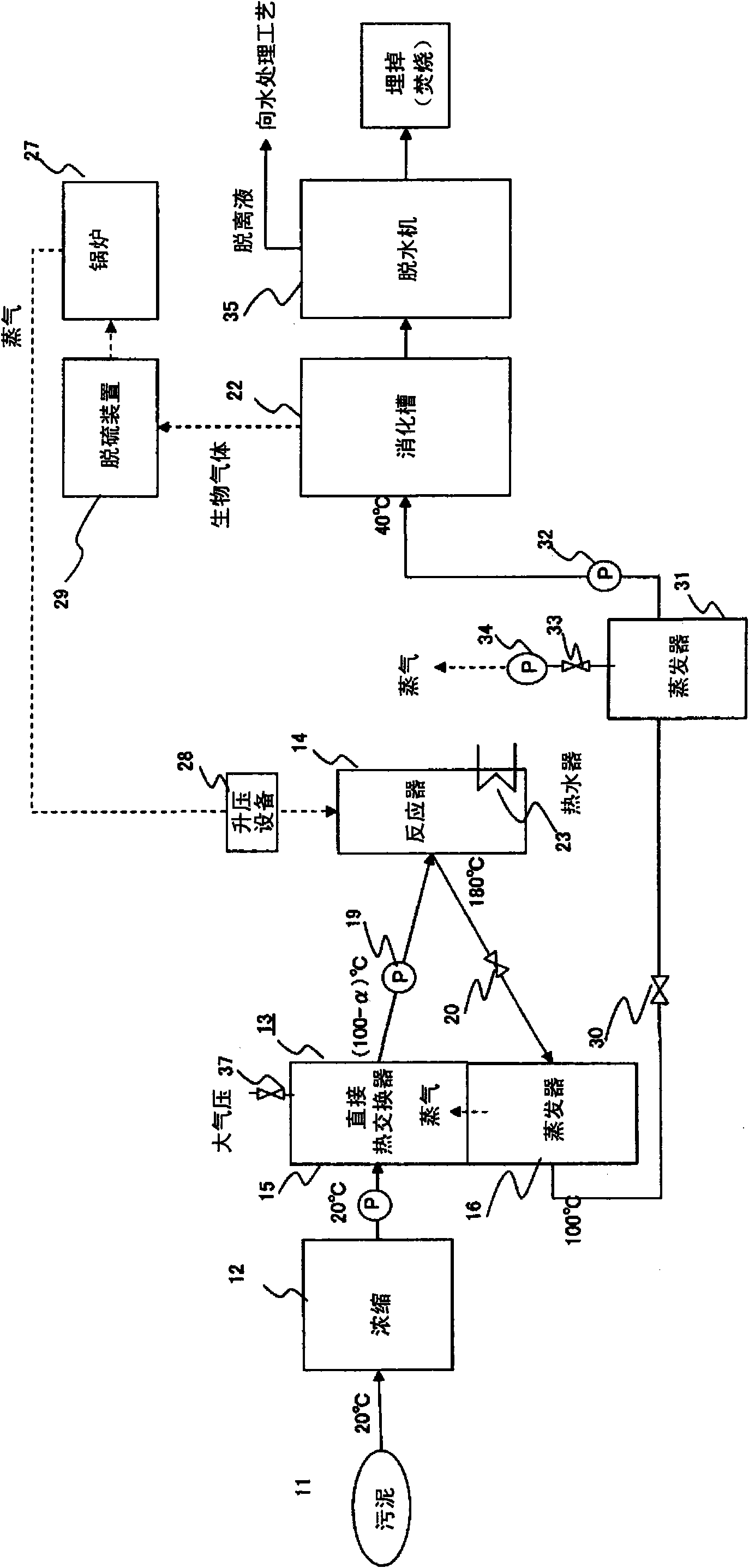

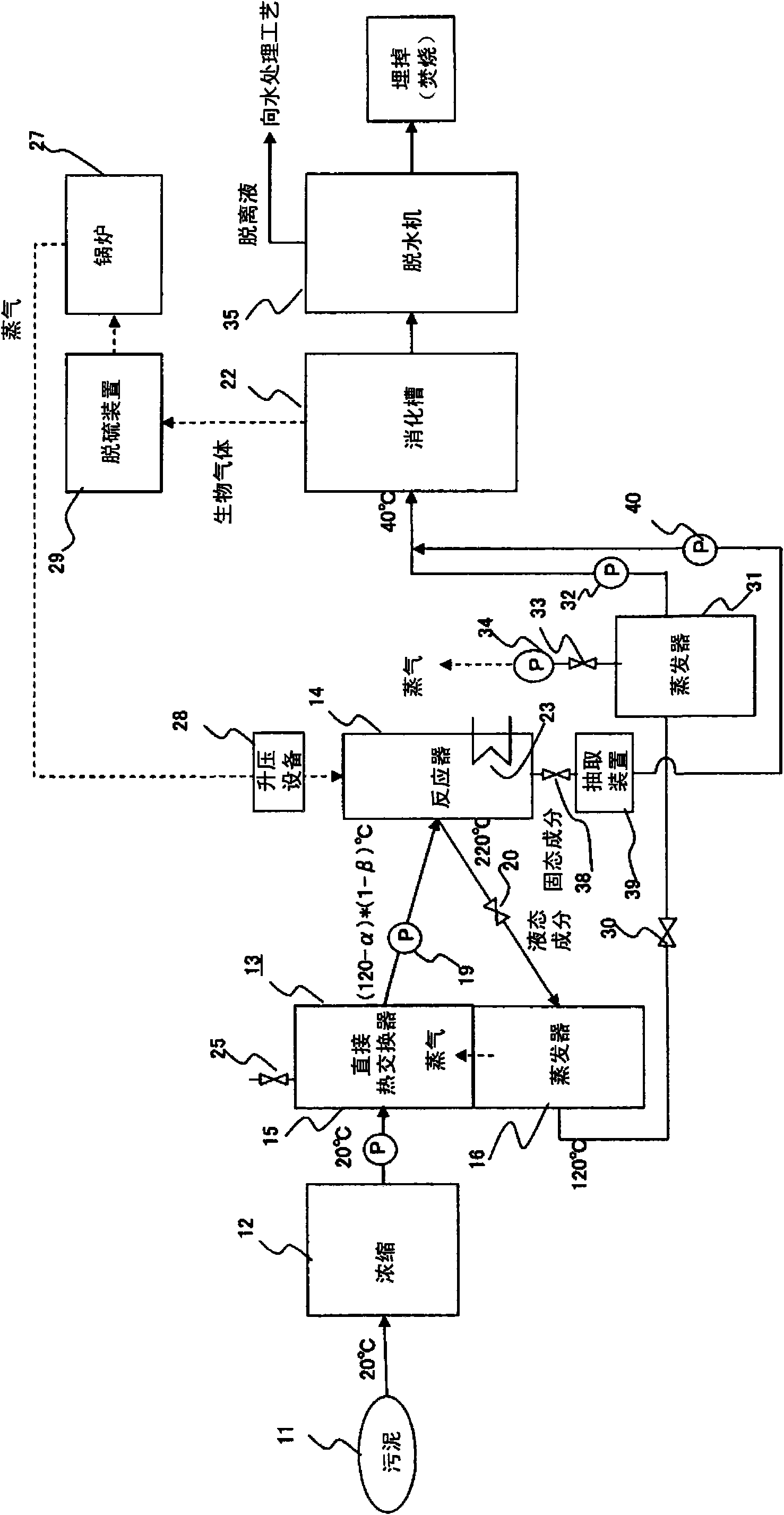

[0038] figure 1 is a block diagram showing the structure of this embodiment. figure 1 The sludge treatment system shown has a concentrator 12 for concentrating sludge 11 containing many organic substances to be treated, a preheating device 13 for the concentrated sludge, and preheating the preheated sludge under a predetermined pressure. Reactor 14 for heating and heat treatment.

[0039] The preheating device 13 is, for example, as shown in Japanese Patent Application Laid-Open No. 2007-21300, in which a direct heat exchanger unit 15 is arranged on the upper part of a common container, and an evaporator unit 16 is arranged on the lower part to integrate them, so that the evaporation at the lower part The high-temperature steam generated in the tank part 16 directly contacts and warms the sludge introduced into the upper direct heat exchanger part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com