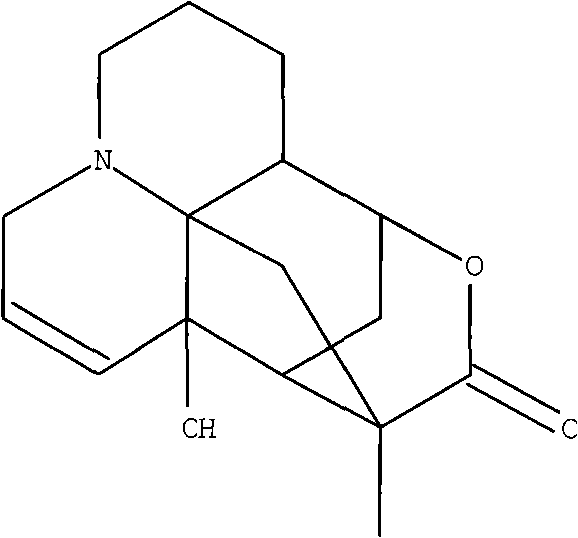

Method for preparing annotine

A technology of cenmanine and crude drug, which is applied in the field of preparation of cenmanine extraction from plants, can solve the problems such as the unsuitable industrial production process report of cenmanine, and achieve the advantages of large-scale production operation, low energy consumption and pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 10Kg of the whole Lycopodium clover, crush it, add hydrochloric acid aqueous solution with pH=2 for percolation, the percolation speed is 5L / min, collect the percolation solution with 5 times the volume of the crude drug, filter, concentrate to 1ml / g crude drug, concentrate Adjust the pH value to 12 with ammonia water, add an equal volume of ethyl acetate to extract twice, combine the ethyl acetate layers, recover the solvent under reduced pressure and dry to obtain the total alkaloids, add them to an alumina chromatography column, elute with methanol, and collect the initial 4 times the column volume of the eluate, recovered the solvent, added acetone to crystallize, separated and dried to obtain 13.5 g of ethanine, which was detected by HPLC with a purity of 99.1%.

Embodiment 2

[0019] Take 10Kg of whole Lycopodium clover, crush it, add pH=5 aqueous hydrochloric acid solution for percolation, the percolation rate is 20L / min, collect 8 times the volume of crude drug quality, filter, concentrate to 1ml / g crude drug, concentrate Adjust the pH value to 14 with ammonia water, add an equal volume of ethyl acetate to extract 4 times, combine the ethyl acetate layers, recover the solvent under reduced pressure and dry to obtain the total alkaloids, add them to an alumina chromatography column, elute with methanol, and collect the initial 4 times the column volume of the eluate, recovered the solvent, added acetone to crystallize, separated and dried to obtain 10.5 g of ethanine, which was detected by HPLC with a purity of 97.9%.

Embodiment 3

[0021] Take 10Kg of whole Lycopodium clover, crush it, add pH=3 aqueous hydrochloric acid solution for percolation, the percolation rate is 10L / min, collect 6 times the volume of the crude drug, filter, concentrate to 1ml / g crude drug, concentrate Adjust the pH value to 13 with ammonia water, add an equal volume of ethyl acetate to extract three times, combine the ethyl acetate layers, recover the solvent under reduced pressure and dry to obtain the total alkaloids, add them to an alumina chromatography column, elute with methanol, and collect the initial 4 times the column volume of the eluate, recovered the solvent, added acetone to crystallize, separated and dried to obtain 14.6 g of ethanine, which was detected by HPLC with a purity of 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com