Poly-phosphate flame retardant containing DOPO side-chain structure and preparation method thereof

A technology of polyphosphate and flame retardant, which is applied to the structure and preparation of polymeric organophosphorus flame retardants, can solve the problems of poor droplet resistance of flame retardants, and achieve easy control, simple preparation methods, The effect of high temperature

Inactive Publication Date: 2010-09-22

DALIAN UNIV OF TECH

View PDF3 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the experimental results show that the use of flame retardants containing DOPO structures alone has poor droplet resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

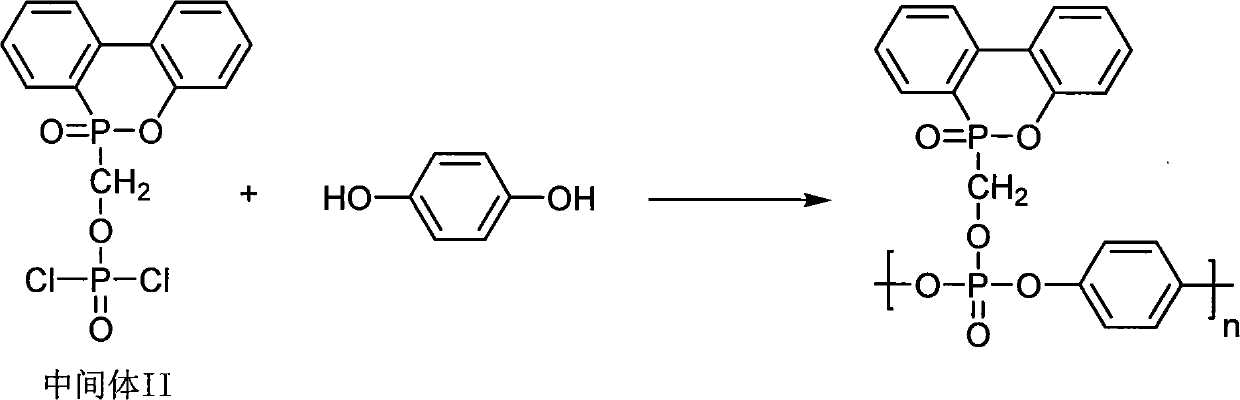

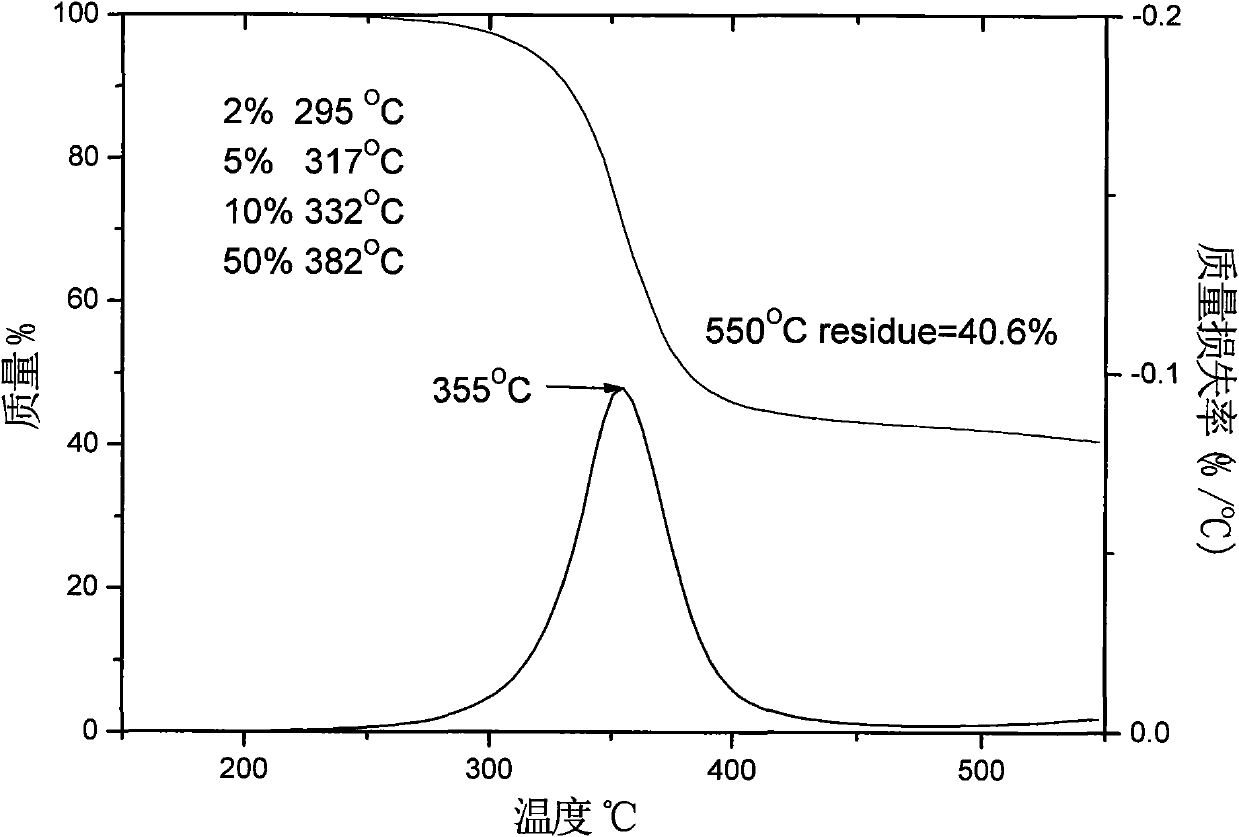

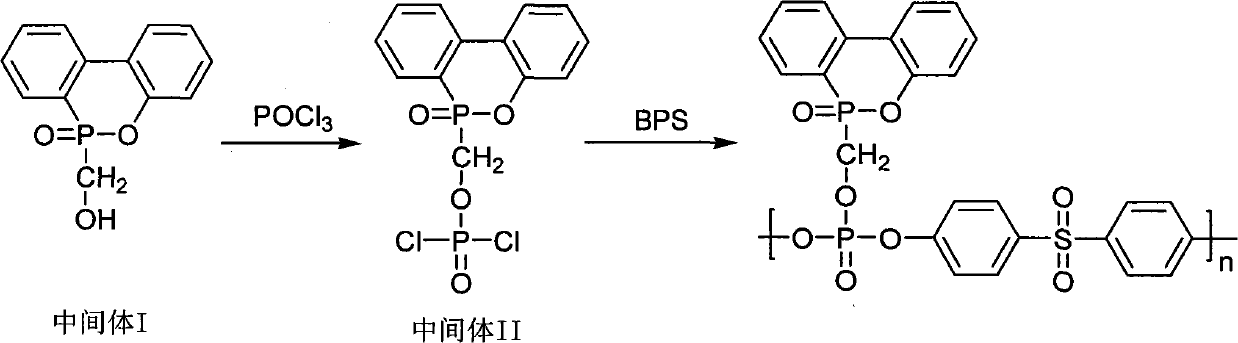

The invention discloses a poly-phosphate flame retardant containing a DOPO side-chain structure and a preparation method thereof, belonging to the technical field of polymeric organic phosphorus flame retardant structures and the preparation method thereof. The flame retardant is characterized by comprising the following repeating unit structure: wherein n=5-50. The preparation method of the poly-phosphate flame retardant comprises the following steps of: reacting an intermediate I containing the DOPO structure with phosphorus oxychloride to obtain an intermediate II containing phosphorus oxychloride, and fusing and polymerizing the intermediate II and a bisphenol compound to obtain the poly-phosphate flame retardant containing the DOPO side-chain structure. The preparation method is simple, and through adjusting Ar categories and ratios, the phosphorus content can be controlled at 11.5-15.5% and the sulfur content can be controlled at 0-5.9%. The flame retardant has the characteristics of favorable thermal stability, high decomposition temperature, favorable char-forming property, and the like, and can be used for flame retardance modification of materials, such as polyester, polyamide, polycarbonate and blends thereof, and the like, with higher processing temperature.

Description

technical field The invention belongs to the technical field of polymeric organophosphorus flame retardant structures and preparation methods thereof, and relates to polyphosphate ester flame retardant structures containing DOPO side chain structures and preparation methods thereof. Background technique With the rapid development of synthetic materials, synthetic plastics, rubber, and fibers are more and more used in various sectors of the national economy and people's production and life, but at the same time, fires caused by ignition of high polymers are also Therefore, people have higher and higher requirements for the flame retardant properties of synthetic materials. Especially in the high-tech field, people not only require flame-retardant materials to have satisfactory flame-retardant properties, but also require materials to have good physical and mechanical properties and electrical properties, processing fluidity, easy recycling of flame-retardant materials, dimens...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K21/14C09K21/12C08G79/04C07F9/6571C08K5/5313

Inventor 郑玉斌闫莉郑楠

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com