High speed steel and productive technology thereof

A production process and technology for high-speed steel, applied in the field of high-speed steel and its production process, can solve the problems of complex powder metallurgy process, large size requirements of atomization device, low yield of powder metallurgy materials, etc. Abrasion resistance, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

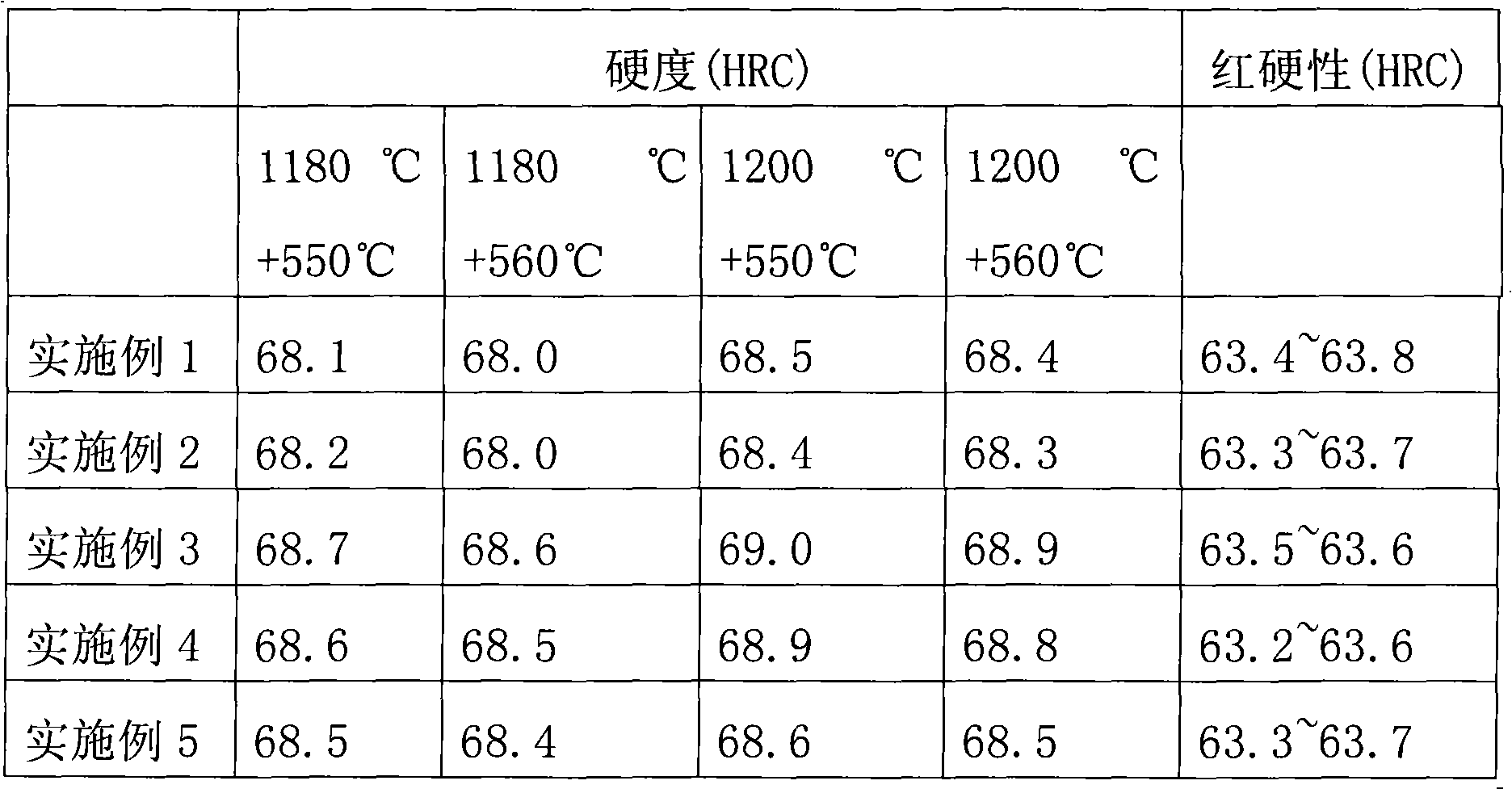

Embodiment 1

[0036] a, batching process: carry out batching according to the composition of the alloy described in table 1;

[0037]b. Melting process: Put the mixed ingredients into the vacuum induction furnace in the melting chamber of the atomization deposition equipment and heat to 100°C higher than the melting point of the alloy, and keep it warm for 20 minutes to make the composition and temperature of the high-speed steel melt in the induction furnace uniform Consistent, then pour the high-speed steel melt into the heated tundish at a speed of 3g / min, the temperature of the tundish is 100°C higher than the melting point of high-speed steel;

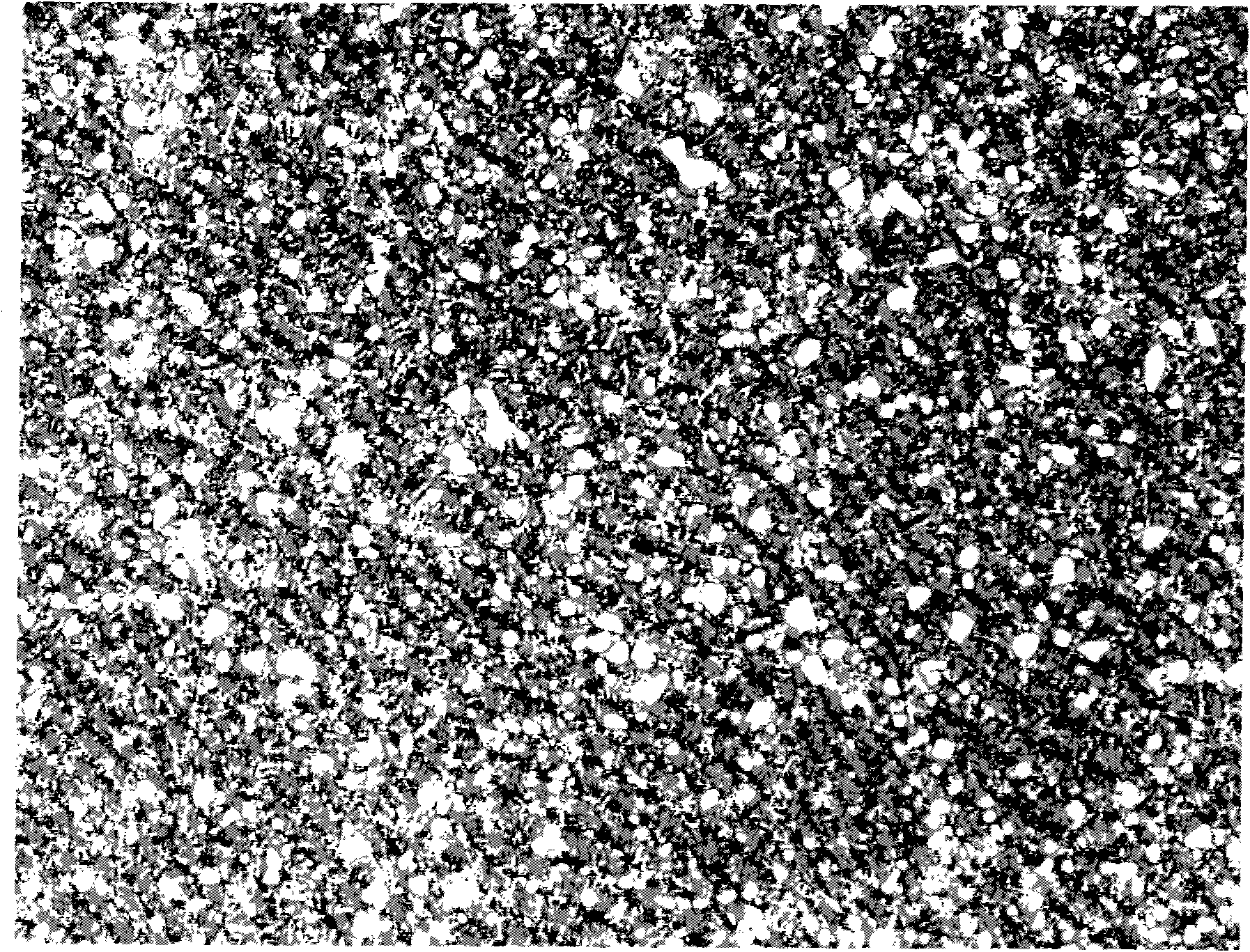

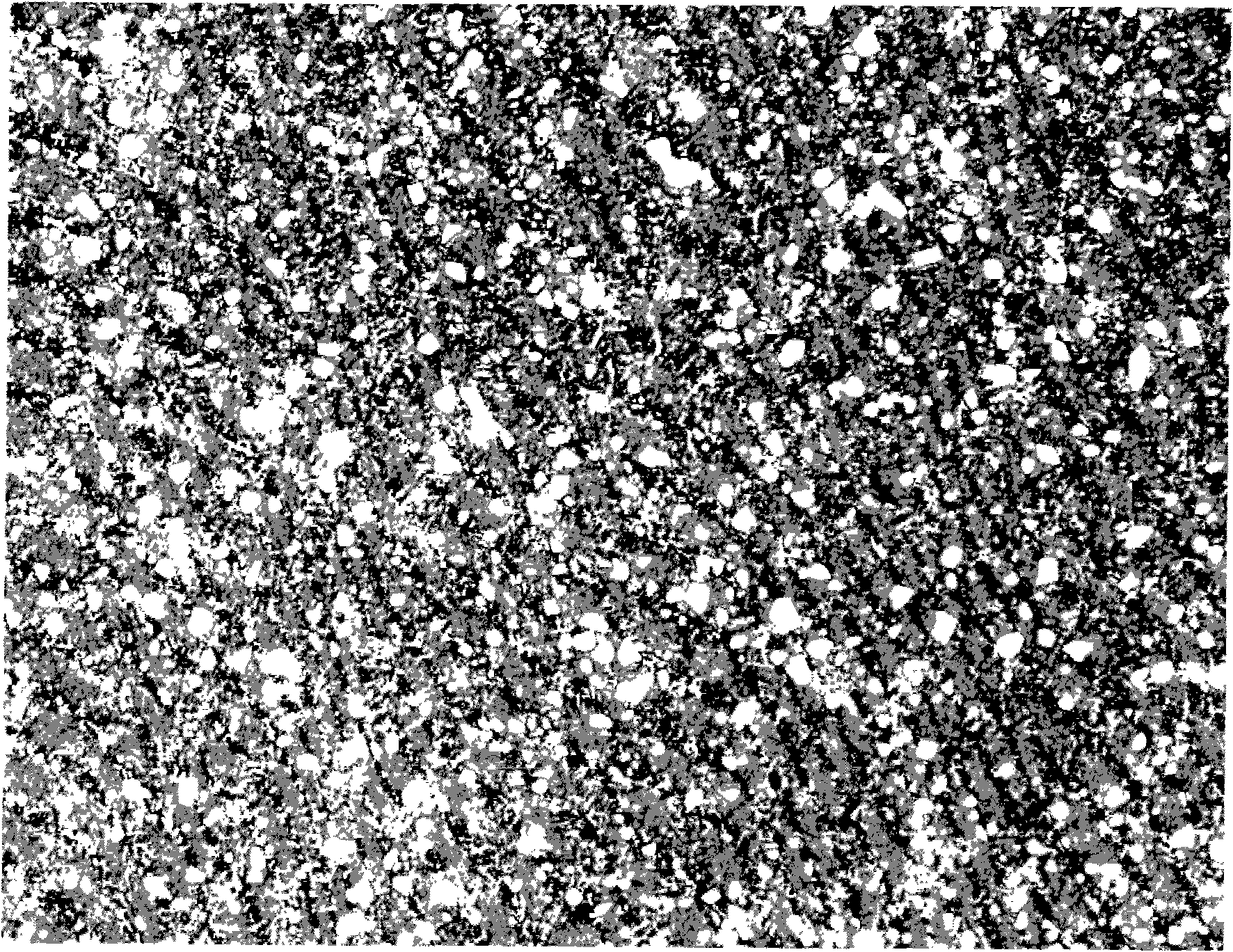

[0038] c. Atomization deposition process: In the physical and chemical chamber, N with a pressure of 2-3 MPa and a purity of >99.9% Wt 2 The gas passes through the atomizing nozzle to atomize the high-speed steel melt into molten droplets, and the molten droplets fly and deposit on the depositor rotating at a speed of 50 rpm to form a columnar ...

Embodiment 2

[0044] a, batching process: carry out batching according to the composition of the alloy shown in Table 1;

[0045] b. Melting process: Put the mixed ingredients into the vacuum induction furnace in the melting chamber of the atomization deposition equipment and heat to 130°C higher than the melting point of the alloy, and keep it warm for 12 minutes to make the composition and temperature of the high-speed steel melt in the induction furnace uniform Consistent, then pour the high-speed steel melt into the heated tundish at a speed of 4g / min, the temperature of the tundish is 130°C higher than the melting point of high-speed steel;

[0046] c. Atomization deposition process: In the physical and chemical chamber, N with a pressure of 2-3 MPa and a purity of >99.9% Wt 2 The gas passes through the atomizing nozzle to atomize the high-speed steel melt into molten droplets, and the molten droplets fly and deposit on the depositor rotating at a speed of 60 rpm to form a columnar dep...

Embodiment 3

[0052] a, batching process: carry out batching according to the composition of alloy shown in Table 1;

[0053] b. Melting process: Put the mixed ingredients into the vacuum induction furnace in the melting chamber of the atomization deposition equipment and heat to 160°C higher than the melting point of the alloy, and keep it warm for 14 minutes to make the composition and temperature of the high-speed steel melt in the induction furnace uniform Consistent, then pour the high-speed steel melt into the heated tundish at a speed of 6g / min, the temperature of the tundish is 170°C higher than the melting point of high-speed steel;

[0054] c. Atomization deposition process: In the physical and chemical chamber, N with a pressure of 2-3 MPa and a purity of >99.9% Wt 2 The gas passes through the atomizing nozzle to atomize the high-speed steel melt into molten droplets, and the molten droplets fly and deposit on the depositor rotating at a speed of 50-90 rpm to form a columnar depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com