Method for improving over-wet cohesive soil by using curing agent

A curing agent and over-humidity technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of high price, limited by soil type, insufficient strength, etc., achieve low cost, improve physical and mechanical properties, and facilitate The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

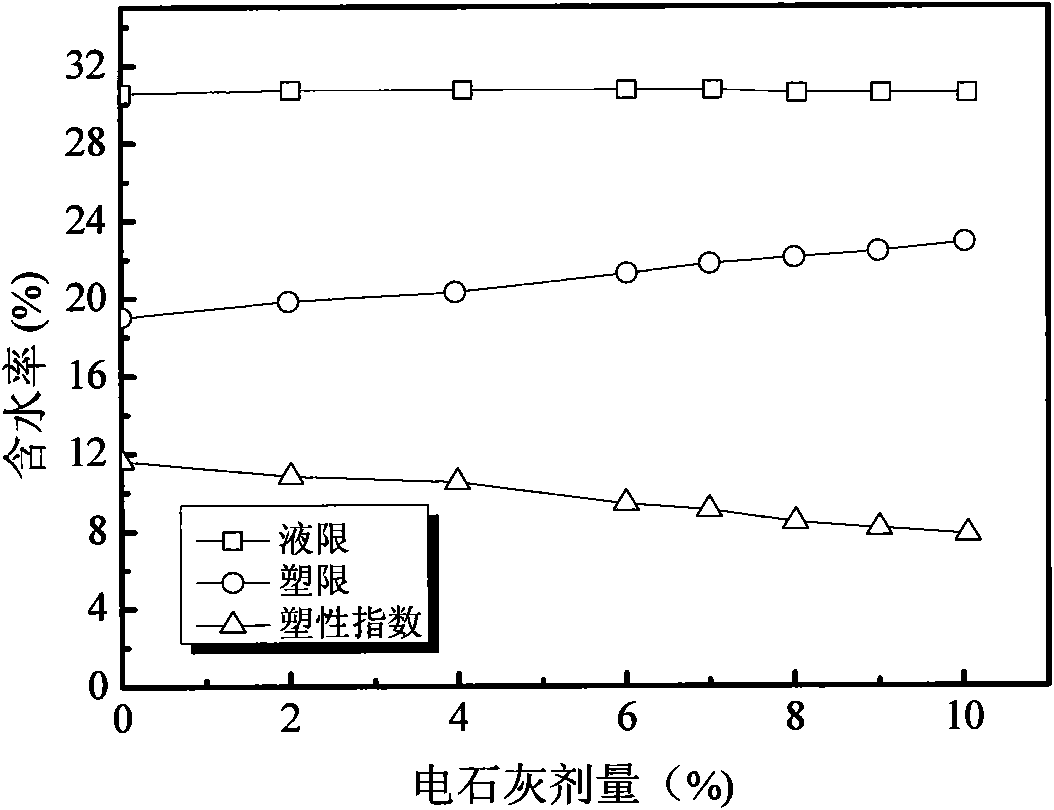

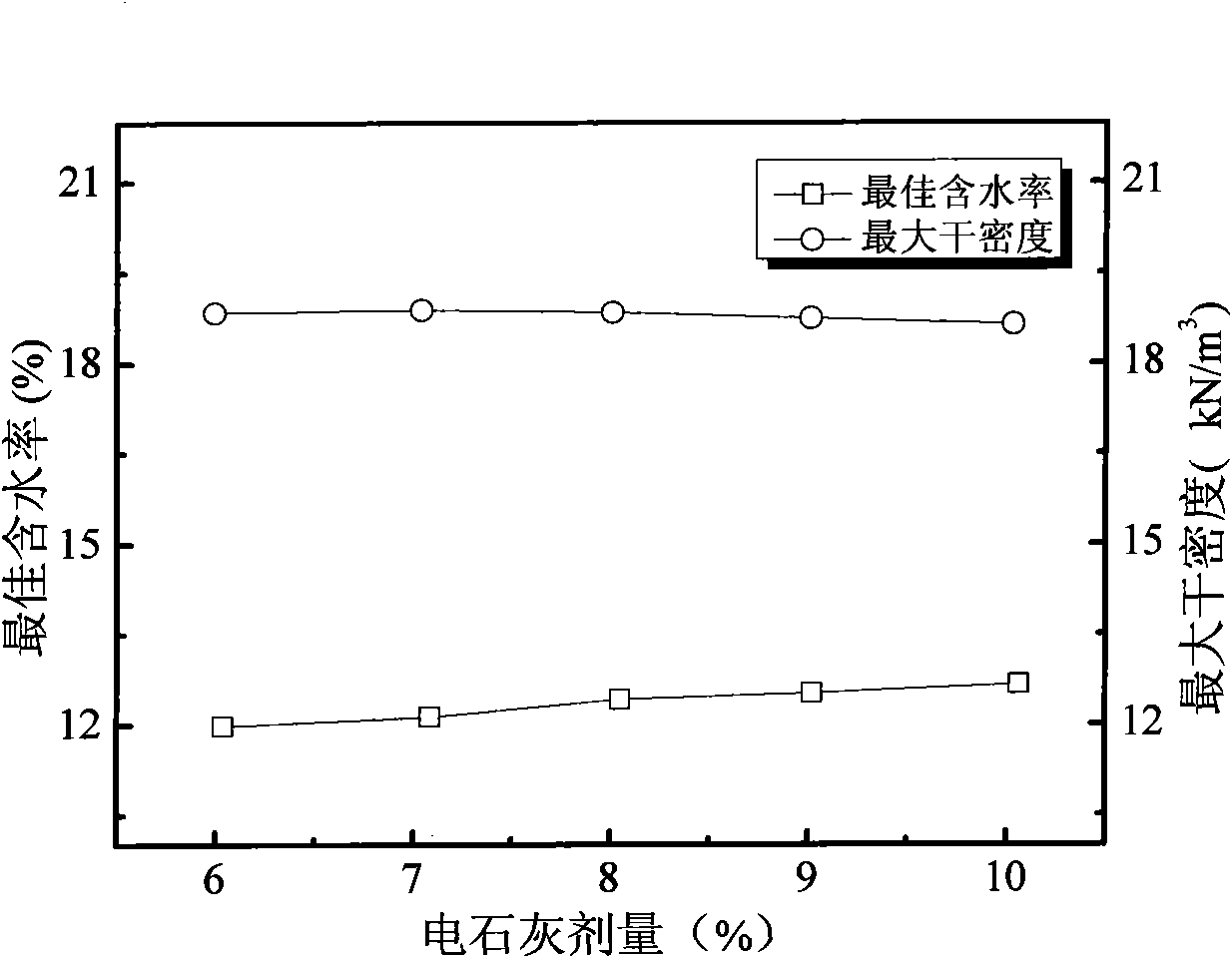

[0046] A method for improving over-wet cohesive soil with a curing agent, characterized in that the plasticity index of the over-wet cohesive soil is greater than 10, the curing agent used is carbide slag, and the amount of carbide slag is 4-4% of the weight of the over-wet cohesive soil. 8%.

[0047] Specific embodiments of the present invention are described in more detail below:

[0048] 1. Carbide slag improved over-wet clay technology

[0049] The effect of calcium carbide slag on wet soil is planned to be evaluated through the combination of indoor test and theoretical analysis, mainly from the following aspects:

[0050] ①Study the physical and mechanical properties of calcium carbide slag-improved over-wet soil;

[0051] ②Evaluate the feasibility of improving over-wet soil road with carbide slag;

[0052] ③ Clarify the mechanism of calcium carbide slag improving over-wet soil;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com