Coating for heat exchanger material

A technology for heat exchangers and coatings, applied in coatings and other directions, can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

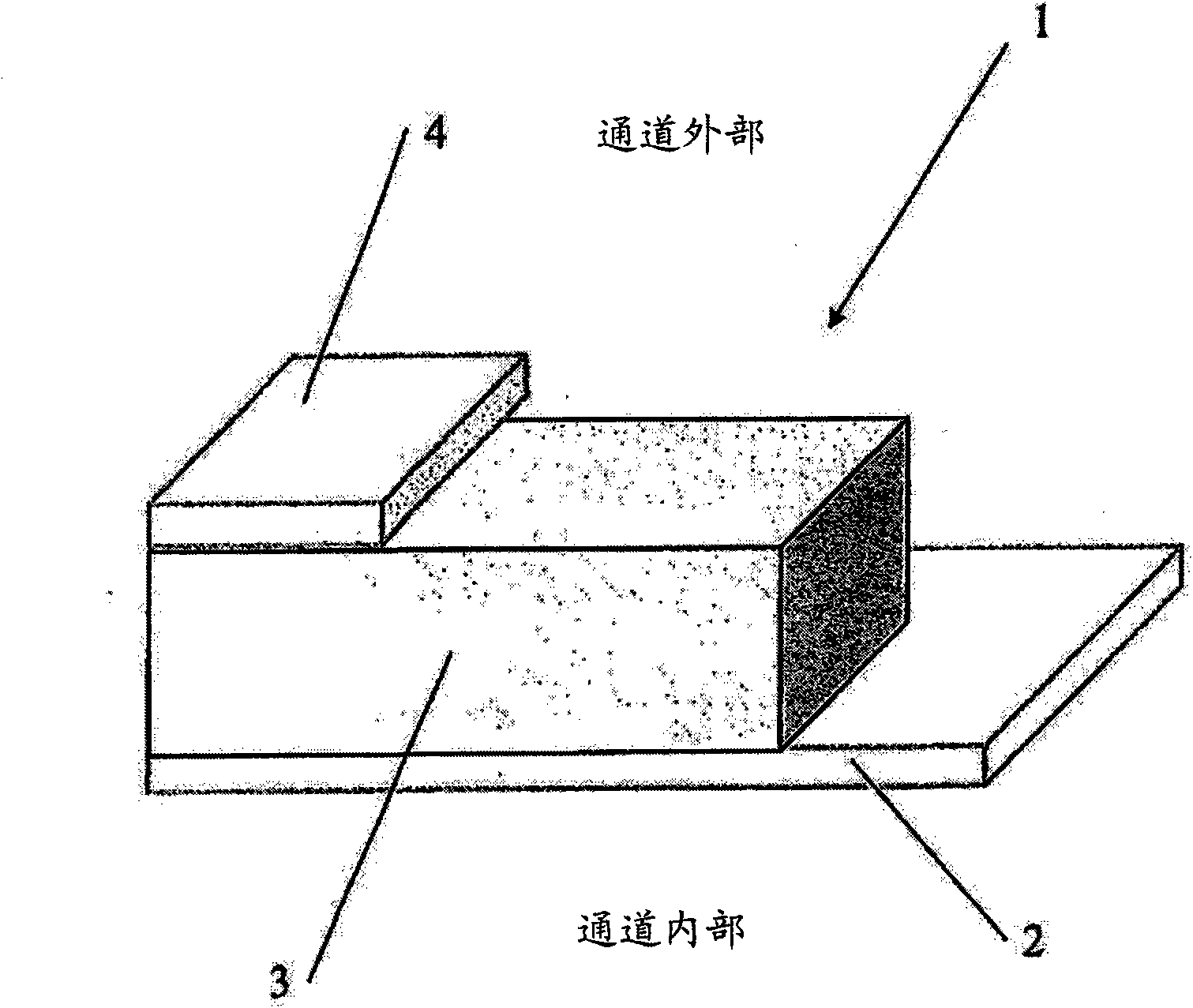

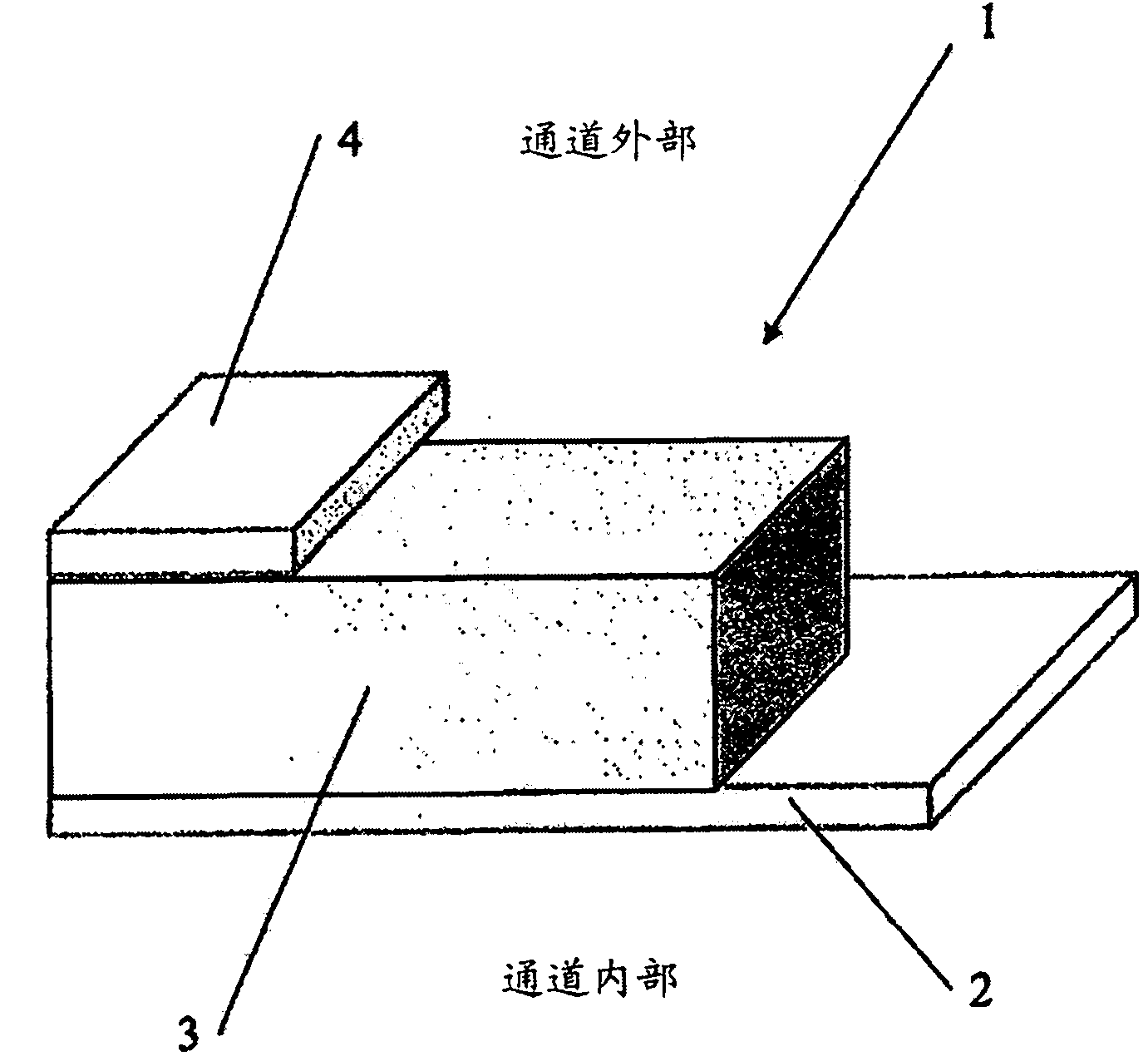

[0032] In the following, the invention is illustrated by a composite material piece comprising tubes (more precisely flat tubes) fixed to a heat exchanger to form a heat exchange tube bundle, but this composite material piece can also be envisaged as a production plate or Other walls are used to form channels in the heat exchanger.

[0033] exist figure 1 In , schematically shown is a wall 1 of a composite material part according to the invention. Furthermore, it should also be noted that in the wall of the existing composite material there are also three layers in the same way, namely the coating 2 , the core 3 and the peripheral layer 4 .

[0034] The invention concerns here the coating 2 and optionally the core 3 in combination with this coating 2 .

[0035] The coating 2 and the peripheral layer 4 are applied to the core 3 of the wall of the composite piece / wall of the pipe in a completely conventional manner without any modifications or special steps. The process / metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com