Preparation method of disodium stannous citrate crystal

A technology of trisodium citrate and citric acid, which is applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of many reaction steps, difficulty in production operation, large amount of waste water, etc., and achieve simplified production steps, reduced energy consumption and operation Difficulty, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

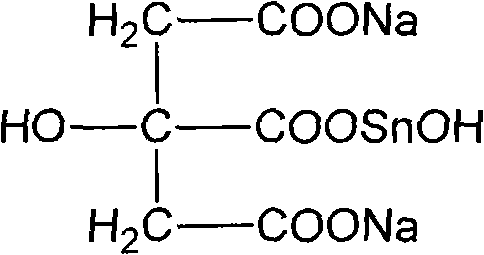

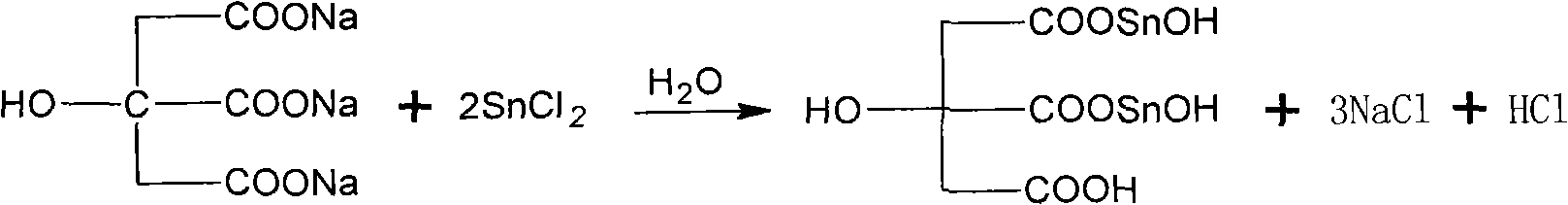

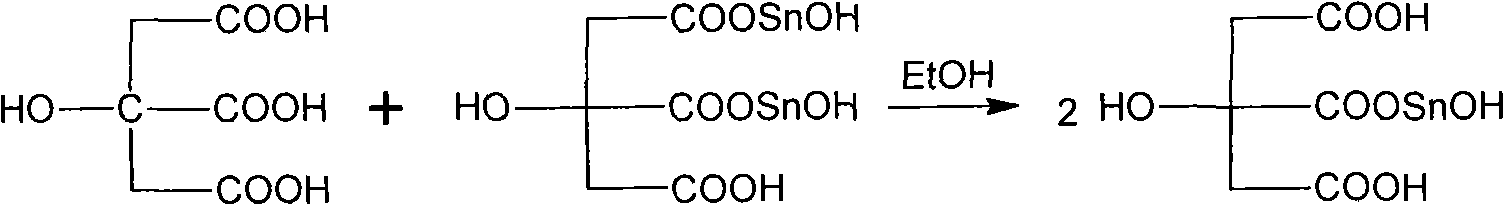

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 294 grams of trisodium citrate in 600 mL of pure water with stirring, filter and set aside. Weigh 451g of stannous chloride and dissolve it in 1000mL of hot water at 80°C, add 0.5g of metal tin powder, keep warm and stir for half an hour, then heat filter. Add the above clarified trisodium citrate solution into the stannous chloride filtrate under stirring at room temperature, and adjust the pH value of the reaction system to 4-5 with hydrochloric acid and / or sodium hydroxide to prepare a suspension of stannous citrate. Heat to 95°C, continue to stir and react for 0.5 hours, cool to room temperature, filter, wash with pure water to remove sodium chloride, and try to dry the water to obtain the intermediate of stannous citrate.

[0030] Add wet stannous citrate into 1000mL of 95% ethanol, stir evenly, add 192 grams of citric acid at 50°C, continue to stir and react for 1 hour, then add a solution of 160 grams of sodium hydroxide dissolved in 1500mL of 95% ethano...

Embodiment 2

[0038] Dissolve 294 grams of trisodium citrate in 600 mL of pure water with stirring, filter and set aside. Weigh 451g of stannous chloride and dissolve it in 1000mL of hot water at 80°C, add 0.5g of metal tin powder, keep warm and stir for half an hour, then heat filter. Add the above clarified stannous chloride filtrate into the trisodium citrate solution under stirring at room temperature, and adjust the pH value of the reaction system to 4-5 with sodium hydroxide and / or hydrochloric acid to obtain a suspension of stannous citrate. Heat to 95°C, continue to stir and react for 0.5 hours, cool, filter, and wash with pure water to remove sodium chloride, then try to dry the water to obtain the intermediate of stannous citrate.

[0039] Add wet stannous citrate into 1000mL of 95% ethanol, stir evenly, add 192 grams of citric acid at 50°C, continue to stir and react for 1 hour, then add a solution of 160 grams of sodium hydroxide dissolved in 1500mL of 95% ethanol to make the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com