Acidproof latex paint and preparation method thereof

A latex paint and emulsion technology, applied in the field of building decoration materials, can solve the problem of lack of acid resistance, and achieve the effects of good stain resistance, reduced dosage, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

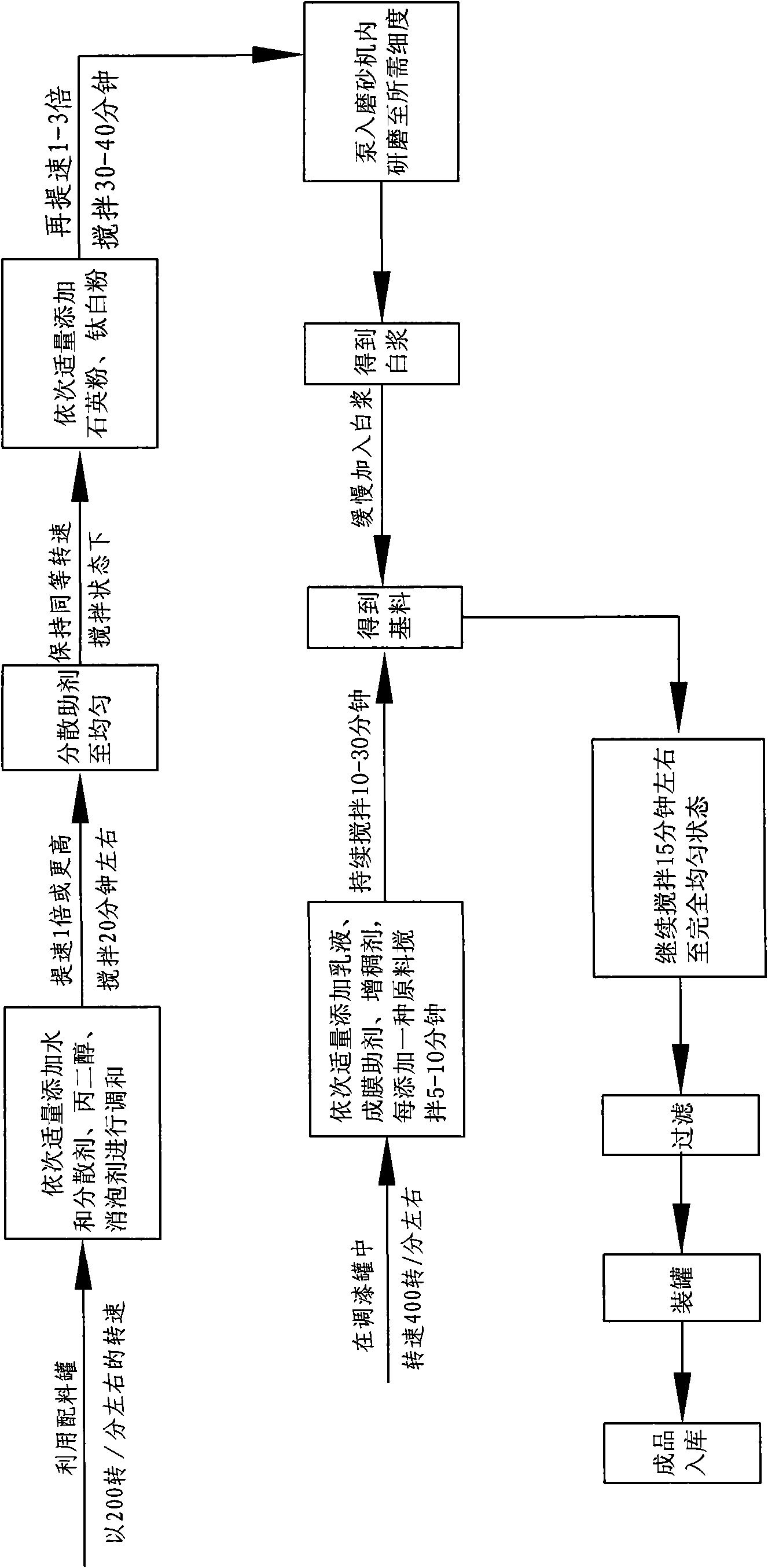

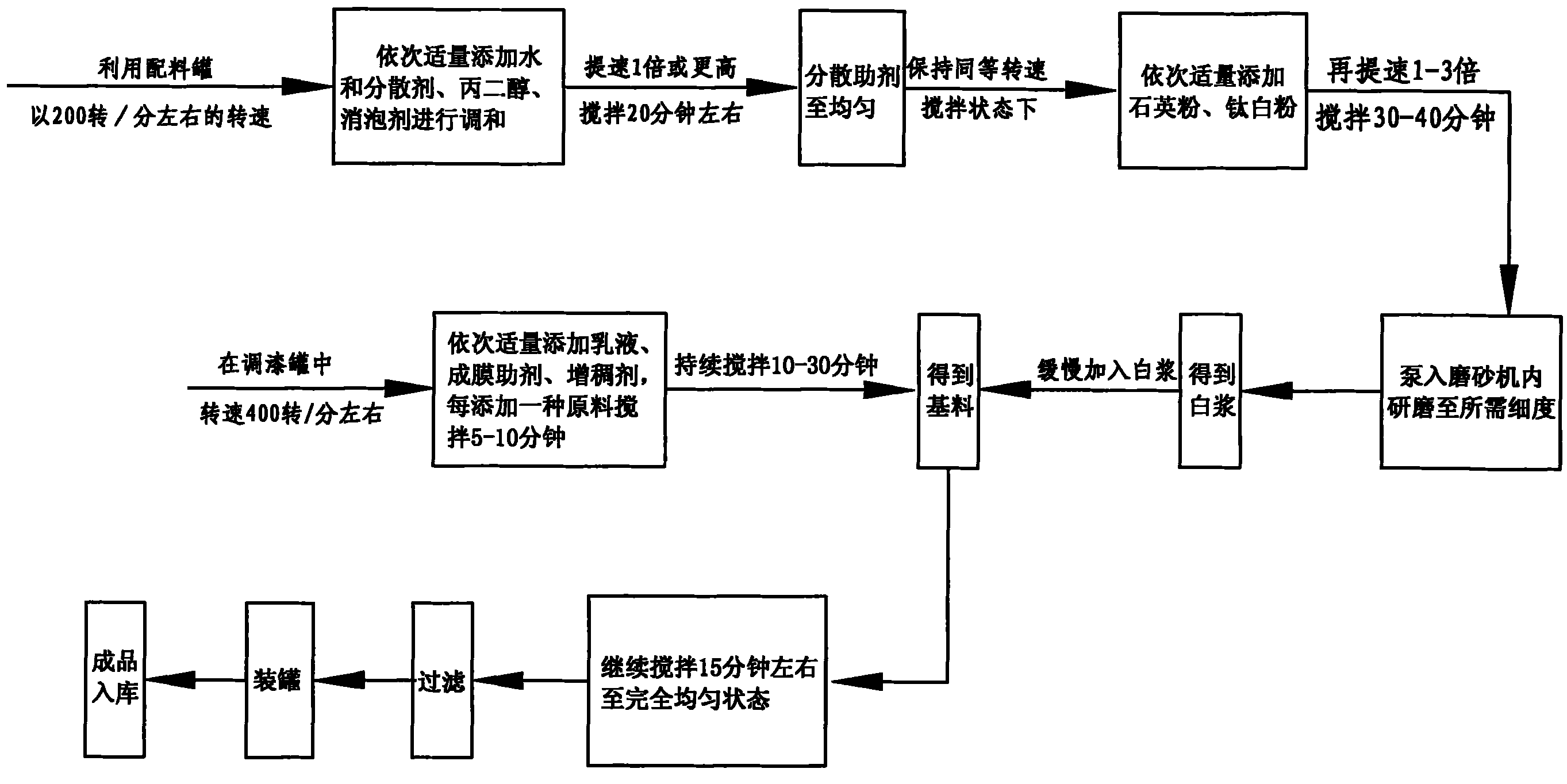

[0030] A preparation method for acid-resistant latex paint, it comprises the following steps:

[0031] a) using a batching tank, under the state of stirring at a rotating speed of 200 rpm, add an appropriate amount of dispersant, propylene glycol, defoamer and water in the raw materials in turn to reconcile;

[0032] b) After that, increase the speed to 400-500 rpm, and continue to stir for about 20 minutes until the additives are evenly dispersed;

[0033] c) under the state of stirring at a rotating speed of 400 r / min, slowly and appropriately add the quartz powder and titanium dioxide in the raw materials according to the amount;

[0034] d) After that, increase the speed to 1000-1200 rpm, and continue to stir for 30-40 minutes; then pump it into a sand mill and grind it to the required fineness; that is, the white paste for coating is obtained;

[0035] e) In the paint mixing tank, at a stirring speed of 400 rev / min, sequentially add an appropriate amount of the emulsion,...

Embodiment 1

[0039] The weight percentage of acid-resistant latex paint raw material of the present invention is: dispersant 0.5%, propylene glycol 2.5%, defoamer 1%, titanium dioxide 15%, quartz powder (SiO 2 ) 28.5%, emulsion 21%, coalescent 2.5%, thickener 2%, water 27%.

[0040] Production can be done in the following steps:

[0041] a) Using a special paint mixing tank, add 27% of water, 0.5% of dispersant, 2.5% of propylene glycol, and 1% of defoamer in the above raw materials in order to blend under the state of stirring at a rotating speed of 200 rpm;

[0042] b) After that, increase the speed to 400 rpm, and continue to stir for 20 minutes until the additives are evenly dispersed;

[0043] c) under the state of stirring at a rotating speed of 400 rpm, slowly add 28.5% of quartz powder and 15% of titanium dioxide in the above raw materials according to the amount;

[0044] d) Afterwards, increase the speed to 1000 rpm, and continue stirring for 30 minutes; then pump it into a san...

Embodiment 2

[0049] The weight percent of acid-resistant latex paint raw material of the present invention is: dispersant 2%, propylene glycol 1%, defoamer 0.05%, titanium dioxide 8%, quartz powder (SiO 2 ) 44%, emulsion 15%, coalescent 0.5%, thickener 0.5%, water 28.95%.

[0050] Production can be done in the following steps:

[0051]a) Using a batching tank, under the state of stirring at a rotating speed of 200 rpm, add 28.95% of water, 2% of dispersant, 1% of propylene glycol, and 0.05% of defoamer in the above raw materials in order to reconcile;

[0052] b) After that, increase the speed to 500 rpm and continue stirring for 25 minutes until the additives are evenly dispersed;

[0053] c) under the state of stirring at a rotating speed of 400 rpm, slowly add 44% of quartz powder and 8% of titanium dioxide in the above raw materials according to the amount;

[0054] d) Afterwards, increase the speed to 1200 rpm, and continue to stir for 40 minutes; then pump it into a sand mill for g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com