Conductor electric exploding plasma-based low-energy metal ion implantation (PBLEMII) device

A technology of metal ion implantation and plasma source, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of inability to handle metal pipe fittings, low bonding strength, and protection failure, and achieve the solution of bonding strength Limited, compact equipment, low manufacturing cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings.

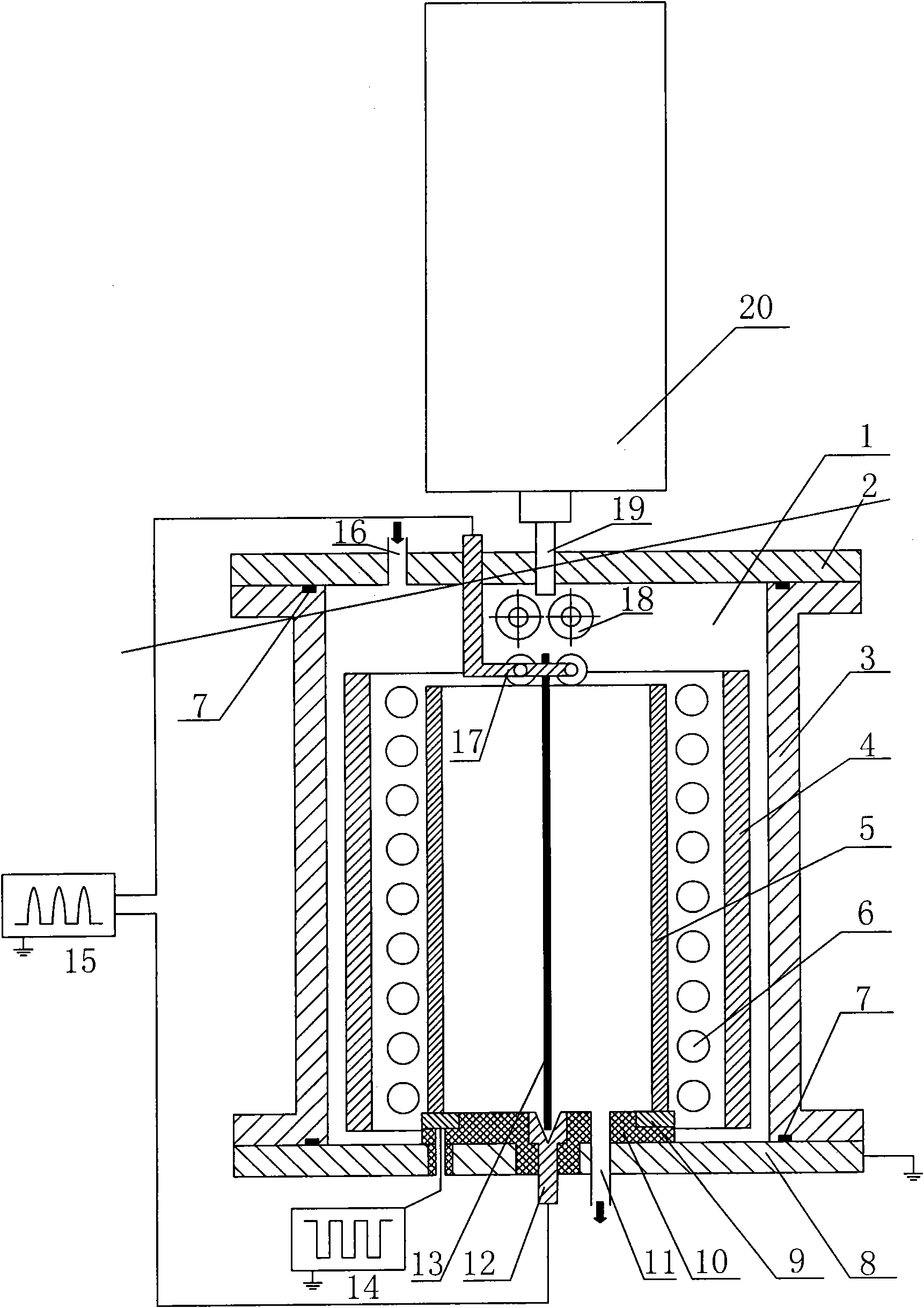

[0023] figure 1 It is a structural schematic diagram of a conductive electric explosion plasma-based low-energy metal ion implantation device of the present invention. As shown in the figure, the disc-shaped upper cover 2 of the device, the cylindrical furnace body 3 and its base 8 form a metal vacuum chamber 1 through a sealing ring 7, and the disc-shaped upper cover 2 is provided with an air inlet 16, and the base 8 There is an air extraction port 11, which is connected with vacuum equipment (such as molecular pump or diffusion pump and mechanical pump unit), and the entire device shell (including the upper cover, furnace body, and base) is grounded; in the metal vacuum chamber 1, the metal pipe fittings 5 ports An electric explosion cathode 17 with a rotating metal runner is arranged at the center; a cylindrical electric explosion anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com