Solution dehumidifying fresh air handling unit combining heat pump drive and evaporative cooling

A technology of evaporative cooling and fresh air unit, applied in space heating and ventilation, details of space heating and ventilation, energy recovery system for ventilation and heating, etc., can solve the problem of affecting the performance of the heat pump system solution dehumidification unit and reducing the performance of the solution dehumidification unit , Condensation temperature rise and other issues, to achieve the effect of improving energy utilization efficiency, improving indoor air quality, and increasing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

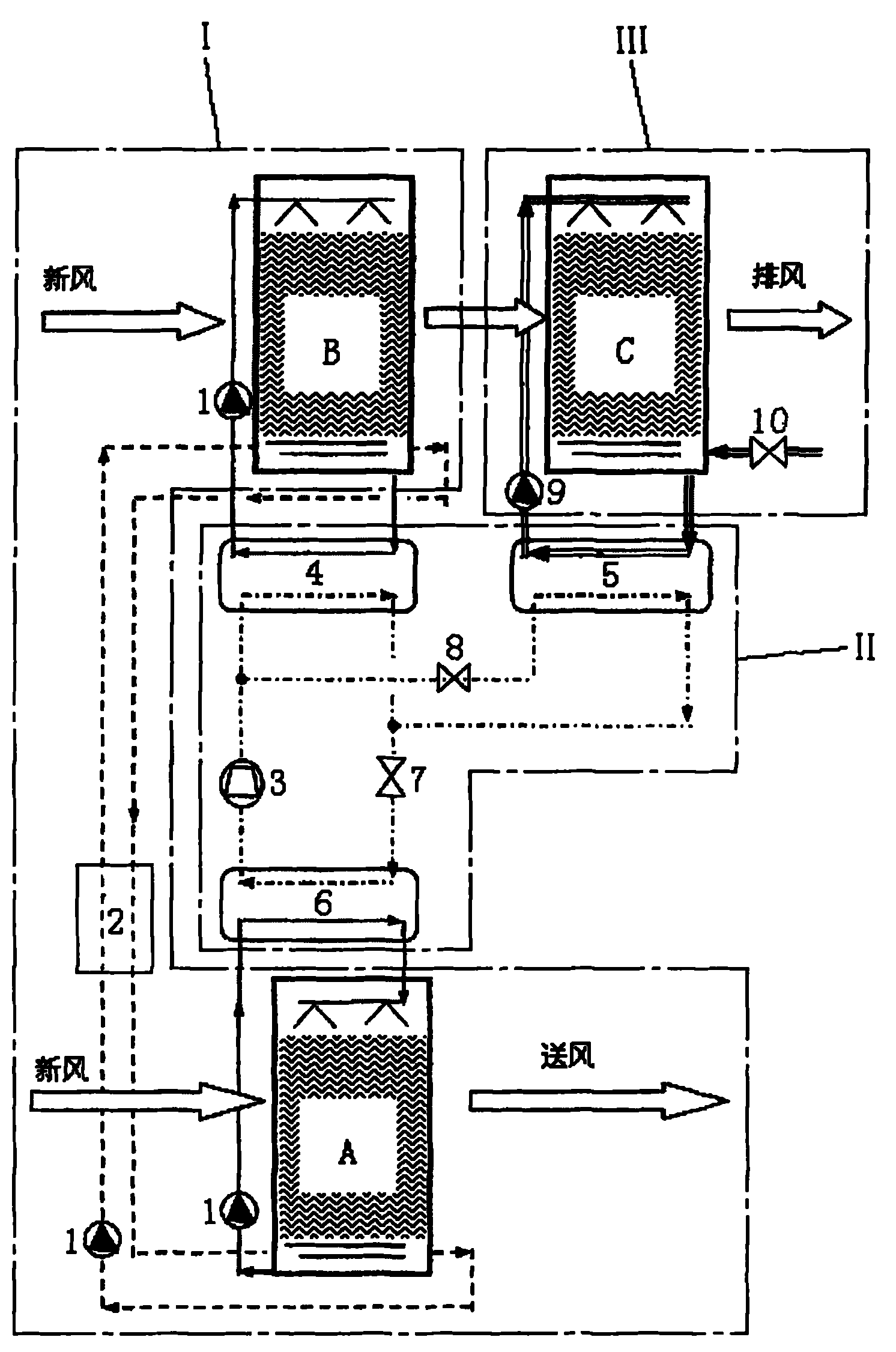

[0018] Such as figure 1 As shown, the fresh air unit in this embodiment includes a solution circulation system I, a heat pump system II and an evaporative cooling water system III.

[0019] The solution circulation system I includes a dehumidification module A, a regeneration module B and a solution circulation pump 1. The dehumidification module A and the regeneration module B are connected through the solution circulation pump 1 to form an interstage solution circulation loop, and the dehumidification module A and the regeneration module B A plate heat exchanger 2 is arranged on the interstage solution circulation loop.

[0020] The heat pump system II includes a compressor 3, a condenser 4 that exchanges heat with the solution, a condenser 5 that exchanges heat with water, an evaporator 6, a throttle valve 7 and a solenoid valve 8, in which the compressor 3, the condenser 4, the throttle Valve 7 and evaporator 6 are sequentially connected to form a circulation loop for hea...

Embodiment 2

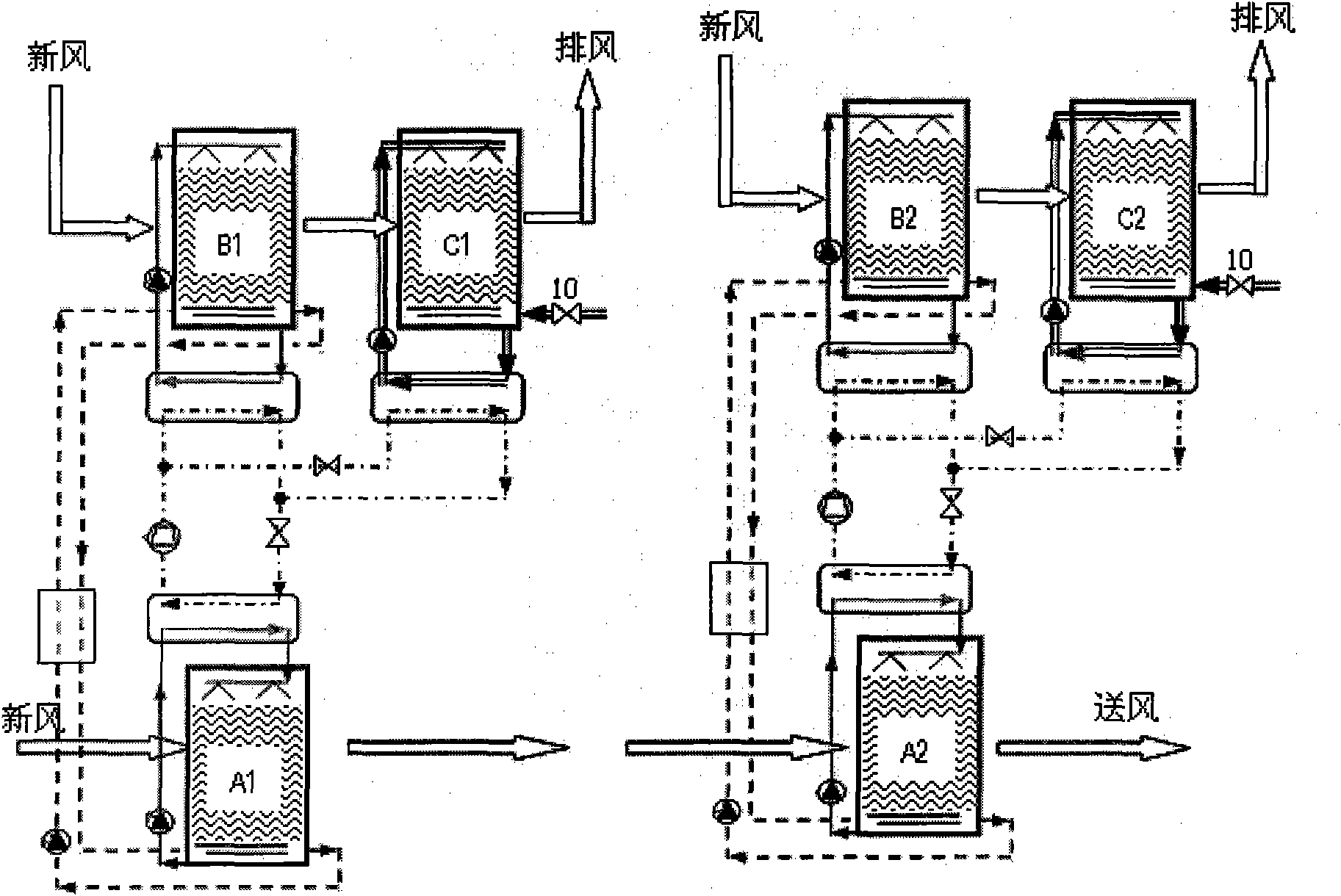

[0025] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the fresh air unit of this embodiment adopts the mode of regenerative fresh air parallel connection, which includes two parallel fresh air units, and the structure of the two fresh air units is the same as that of Embodiment 1, wherein One fresh air for regeneration passes through the regeneration module B1 and the evaporative cooling module C1 in sequence, and the other fresh air for regeneration passes through the regeneration module B2 and the evaporative cooling module C2 in sequence.

[0026] In the above embodiment, the number of fresh air units connected in parallel can also be more than two, and the specific number can be determined according to the usage on site.

Embodiment 3

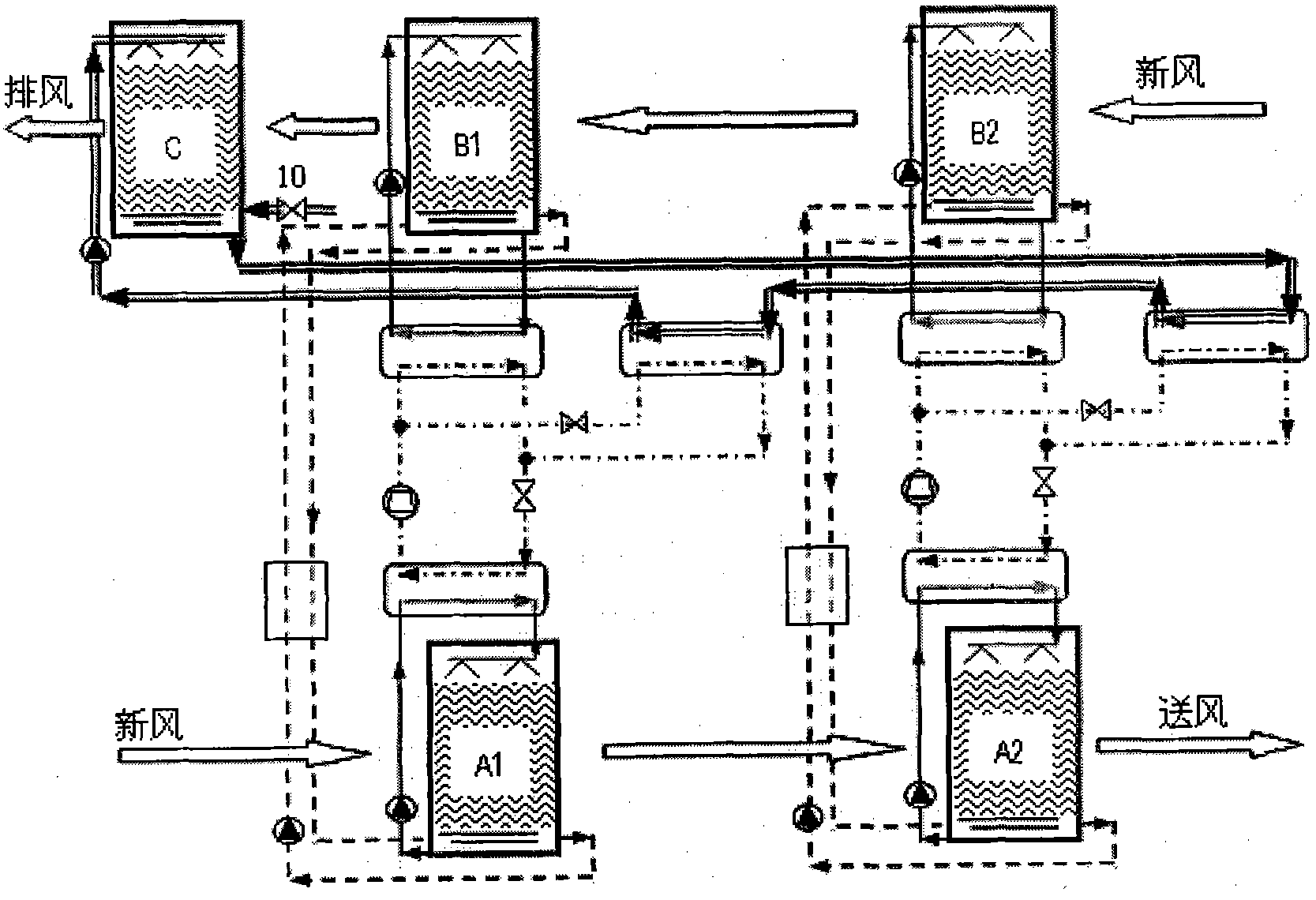

[0028] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the fresh air unit of this embodiment adopts the mode of regenerative fresh air series, which includes two series-connected solution circulation systems I, two series-connected heat pump systems II and an evaporative cooling water System III, and the condenser 5 in the two heat pump systems II and the evaporative cooling module C in the evaporative cooling water system III are connected in series to form a circulation loop for heat exchange with the refrigerant. The outdoor fresh air first passes through the dehumidification modules A1 and A2 in sequence, and then Pass through regeneration modules B2 and B1 in sequence.

[0029]In the above embodiment, the number of the solution circulation system I and the heat pump system II connected in series can also be more than two, and the specific number can be determined according to the usage on site.

[0030] Analyze the flow process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com