Superconductor heat pipe and preparation method of heat transfer medium thereof

A technology of heat transfer medium and superconducting heat pipe, applied in the direction of heat exchange equipment, heat exchange materials, chemical instruments and methods, etc., can solve the problems of reduced heat transfer coefficient, incompatibility, and reduced service life of heat pipes, etc., to achieve Excellent safety, good energy saving performance, and wide application temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

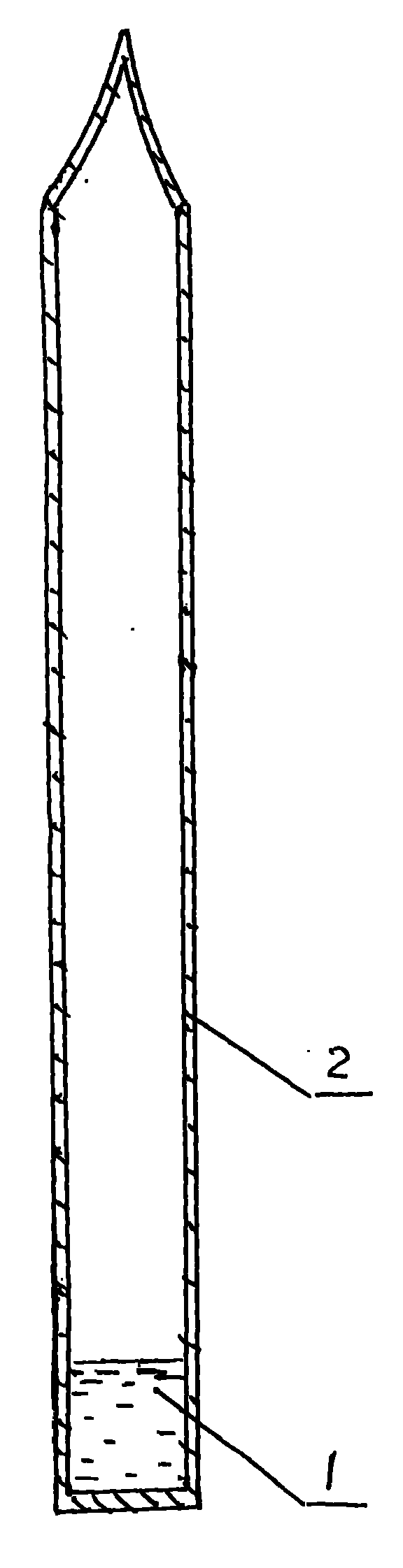

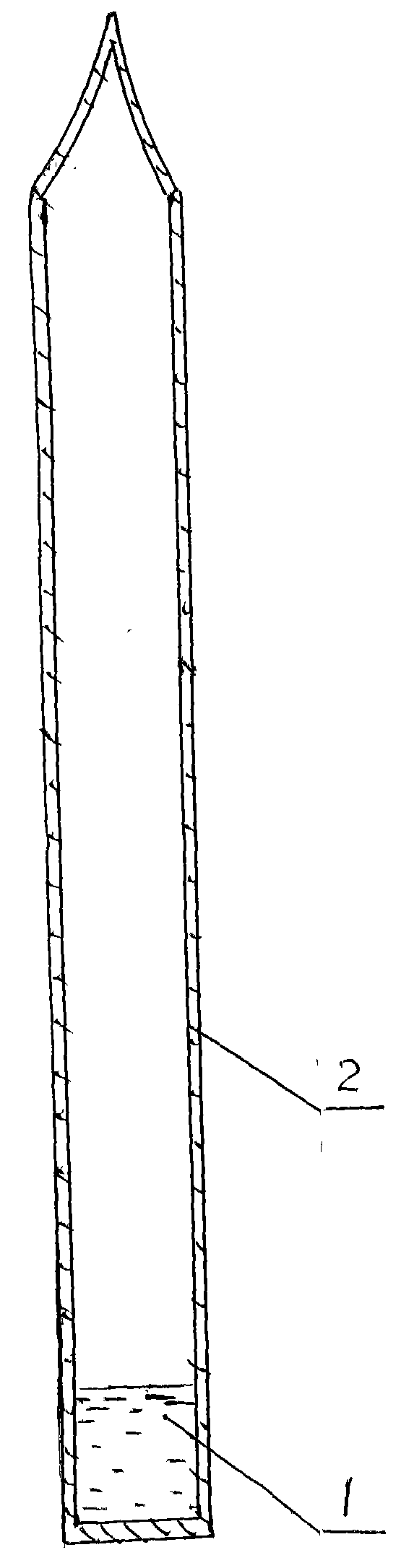

[0015] Referring to Fig. 1, the superconducting heat pipe comprises a metal tube (2) with a closed cavity at both ends storing a heat transfer medium (1), the inner cavity of the metal tube (2) is evacuated, and the heat transfer medium ( 1) The ratio of raw materials by weight is as follows: 1. Boric acid: 3-5 grams 2. Potassium dichromate: 50-60 grams 3. Sodium perborate: 8-10 grams 4. Calcium chloride: 1-3 grams 5. Sodium peroxide: 1-3 grams 6. Manganese dioxide: 1-3 grams 7. Aluminum dihydroxide: 1-1.5 grams 8. Sodium chloride: 1-5 grams, water 1000 grams

Embodiment 2

[0017] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0018] The metal pipe (2) is a copper pipe, the pipe length is 200-80000 mm, the pipe outer diameter is 10-500 mm, and the pipe wall thickness is 1-5 mm.

[0019] The storage capacity of the heat transfer medium (1) in the inner cavity of the metal tube (2) is 8-10% of the inner cavity volume of the metal tube (2).

Embodiment 3

[0021] The preparation method of the heat transfer medium is used to prepare the heat transfer medium (1) in the above-mentioned superconducting heat pipe, and the powdery raw material is selected by weight, and the proportion is as follows: 1. Boric acid: 3-5 grams 2. Potassium dichromate : 50-60 grams 3, sodium perborate: 8-10 grams 4, calcium chloride: 1-3 grams 5, sodium peroxide: 1-3 grams 6, manganese dioxide; 1-3 grams 7, dihydroxide Aluminum 1-1.5 grams 8. Sodium chloride: 1-5 grams, add 1000 grams of 80 ℃ ± 5 ℃ warm water one by one according to the listed order, and stir continuously to dissolve it evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com