Rotation-free step flotation method

A flotation method, non-rotational technology, applied in flotation, solid separation, etc., can solve the problems that the flotation column is difficult to recover useful materials, increase the energy consumption of the flotation process, reduce the unit throughput of the flotation column, etc., and achieve The production process is stable and easy, the effect of saving land and large quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

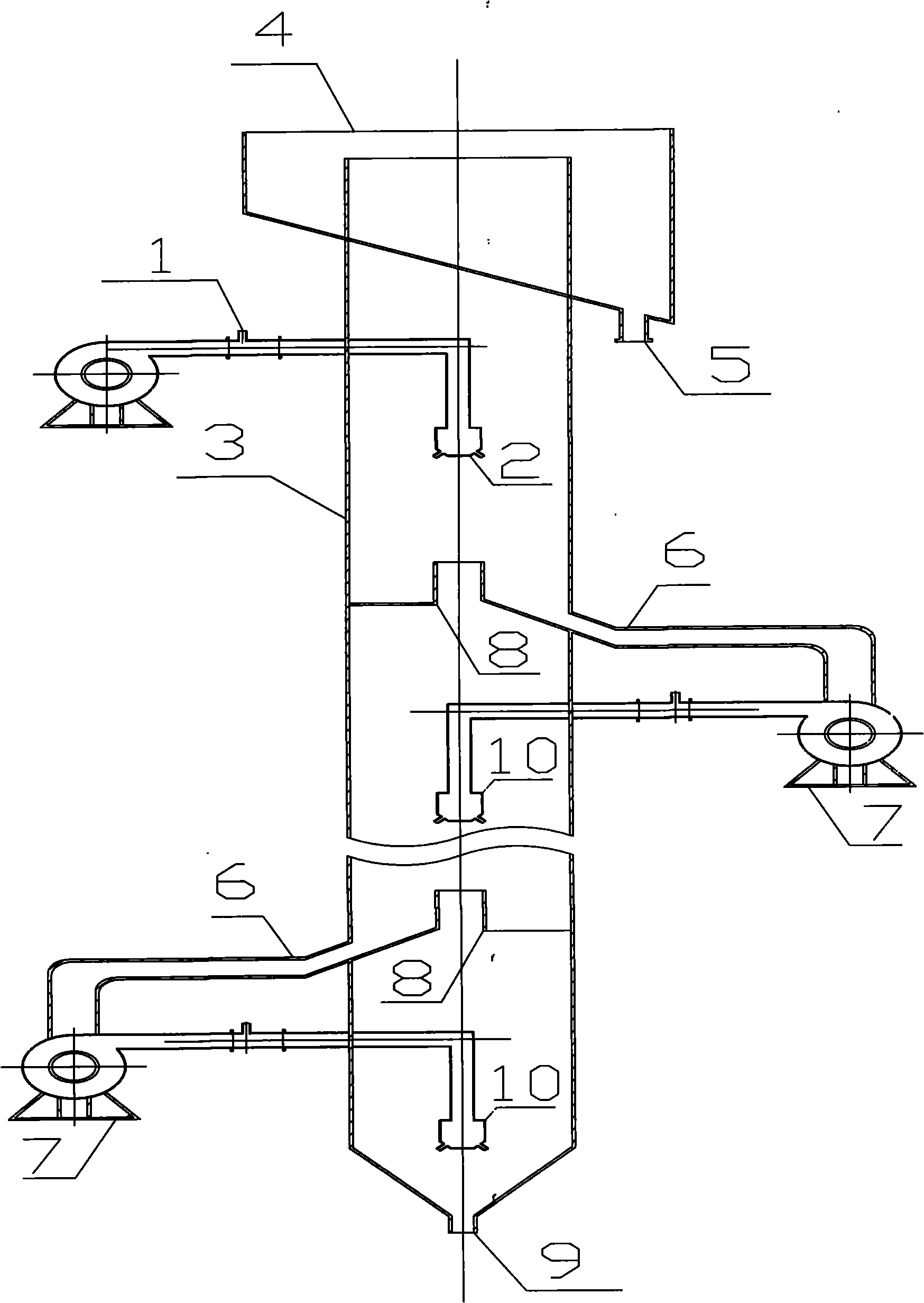

[0021] Under the condition that the fineness after grinding is -0.074mm, accounting for 55%-95%, the raw ore pulp with a concentration of 20%-22% will directly enter the non-transmission cascade flotation column for flotation after the raw ore pulp mixing tank and the flotation agent are reacted. Choose desiliconization. Under the premise of sufficient mineralization and flotation, the concentrate foam overflows from the overflow weir at the upper end of the non-drive flotation tank, and the tailings are discharged from the underflow.

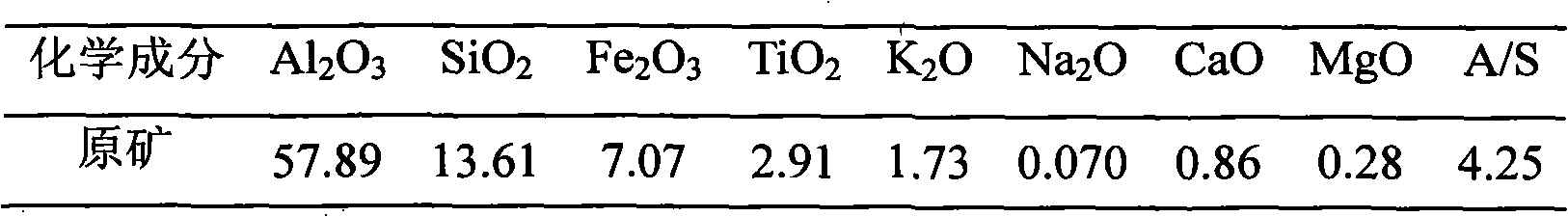

[0022] The industrial production of low-grade bauxite in Henan is used as raw material, and its chemical composition is shown in Table 1 below:

[0023] Table 1

[0024]

[0025] Grinding equipment: ball mill

[0026] Classification equipment: hydrocyclone

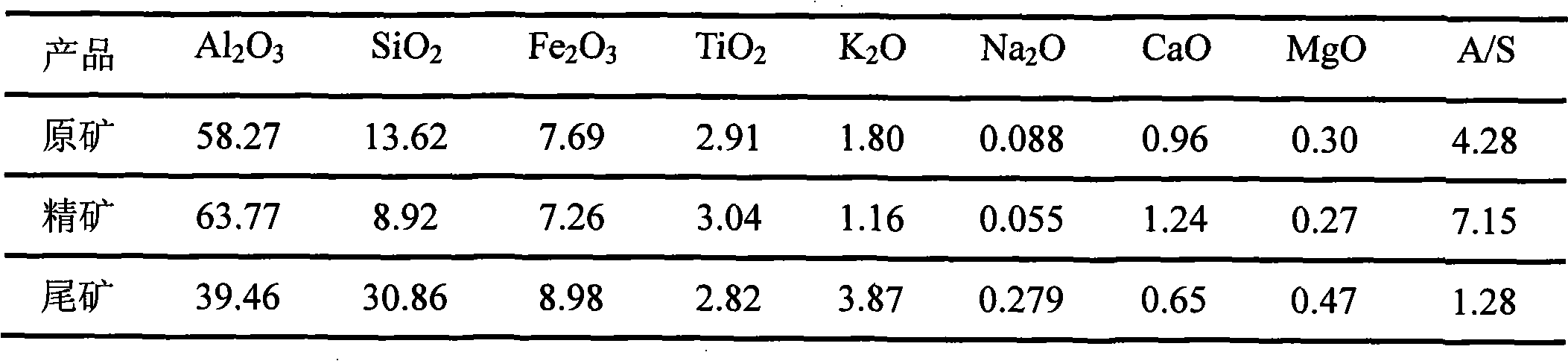

[0027] After a stage of closed-circuit grinding, the overflow fineness of the hydrocyclone -0.075mm accounts for 85.12%, and the pulp with a concentration of 22.5% acts on the raw pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com