Method for processing pine needle semi-finished product and application thereof

A processing method and a technology for semi-finished products, applied in the field of pine needles, can solve the problems of unguaranteed product quality, unfavorable mass production, complex production process, etc., and achieve the effects of protecting pine resources, not easy to break the shelf life, and simple in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of processing method of pine needle semi-finished product of the present invention and utilize this pine needle semi-finished product to make insole, steps are as follows:

[0028] (1) Harvest mature pine needles that are more than two years old in the middle and lower part of the branches of adult pine trees over 5 years old;

[0029] (2) the mature pine needles without deadness of picking are cleaned and dedusted, and then dried;

[0030] (3) drying the pretreated pine needles in an oven at a temperature of 42°C until the moisture content of the pine needles is 10%, to obtain a product;

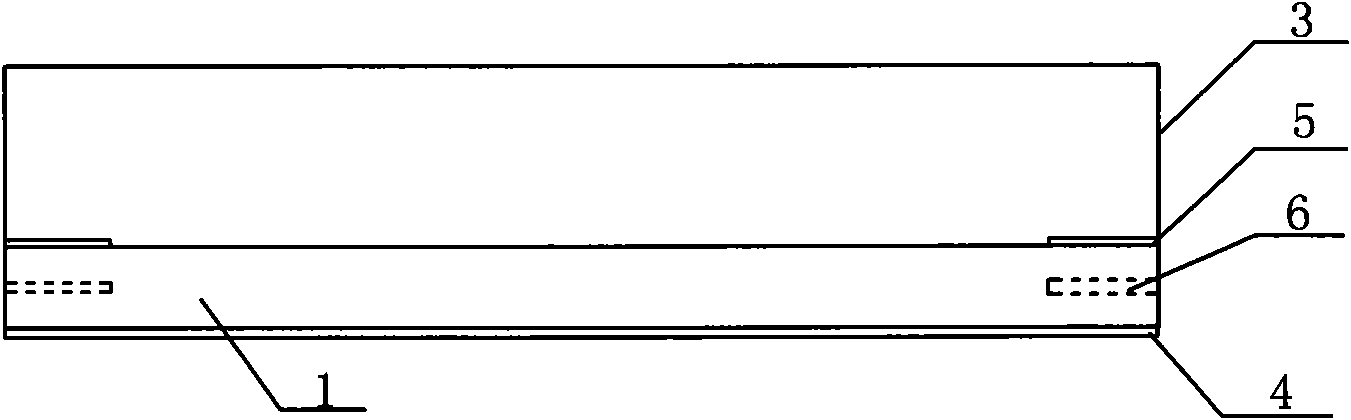

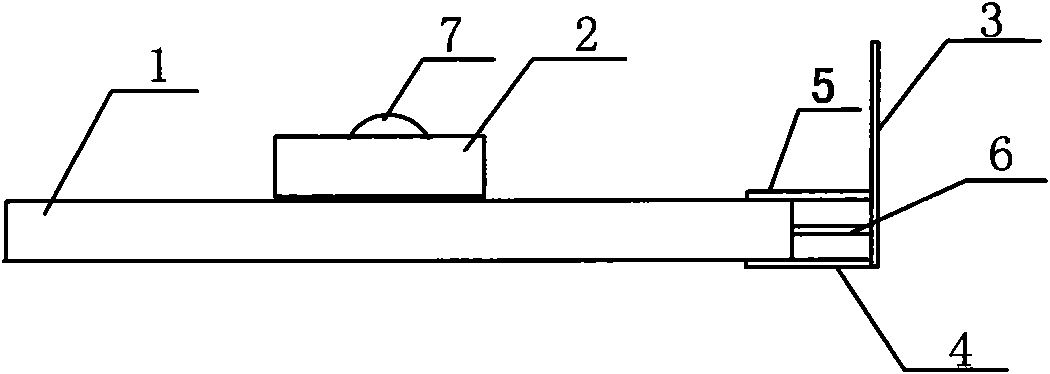

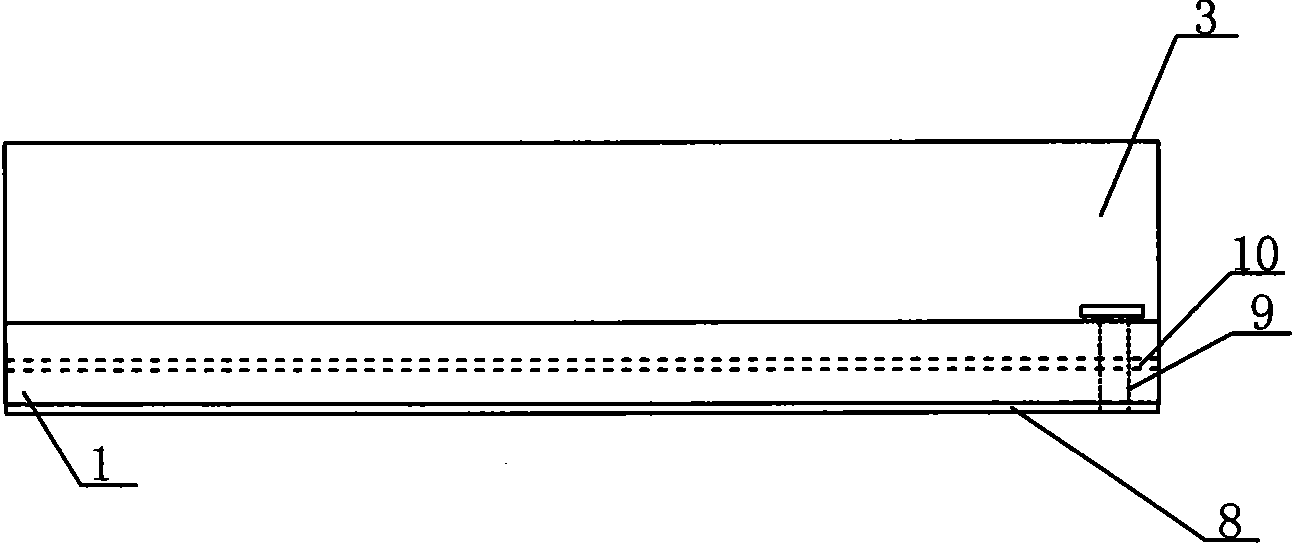

[0031] (4) When the pine needles obtained after the dehydration treatment in step (3) are placed on the base plate 1 of the wire separator, the pine needles are rubbed by the washboard 2 to form a thin layer of evenly distributed pine needles, and then the wire separator is provided with a movable baffle 3 One side of the thin layer of pine needles is tilted so that one end o...

Embodiment 2

[0035] A kind of processing method of pine needle semi-finished product of the present invention and utilize this pine needle semi-finished product to make insole, steps are as follows:

[0036] (1) Harvest mature pine needles that are more than two years old in the middle and lower part of the branches of adult pine trees over 5 years old;

[0037] (2) the mature pine needles without deadness of picking are cleaned and dedusted, and then dried;

[0038] (3) Naturally drying the pretreated pine needles at a temperature of 35°C until the moisture content of the pine needles is 8%, to obtain the product;

[0039] (4) When the pine needles obtained after the dehydration treatment in step (3) are placed on the base plate 1 of the wire separator, the pine needles are rubbed by the washboard 2 to form a thin layer of evenly distributed pine needles, and then the wire separator is provided with a movable baffle 3 One side of the thin layer of pine needles is tilted so that one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com