Ammonia synthesis process

A synthetic ammonia and process technology, applied in the field of synthetic ammonia process, can solve the problems of environmental pollution, large coal consumption and high cost, and achieve the effects of significant economic benefits, environmental protection and energy saving, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

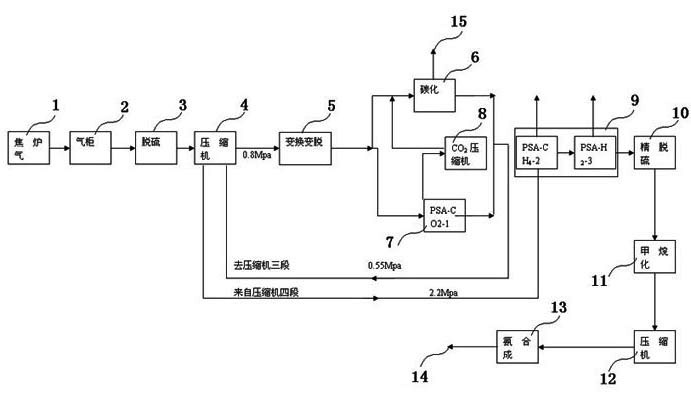

[0021] Such as figure 1 As shown, when preparing ammonia, put the coke oven gas 1 (raw coal gas) in the gas cabinet 2, and convert the coke oven gas through the pressure swing adsorption method removal of naphthalene and tannin extract method desulfurization process device 3 in the gas cabinet 2. Naphthalene removal by pressure adsorption method and desulfurization by tannin extraction method; coke oven gas desulfurized by pressure swing adsorption method and tannin extraction method is sent to reciprocating compressor 4, and then sent to the first and second stages of compression in reciprocating compressor 4 to 0.8Mpa, the compressed gas is shifted and desulfurized by the shift gas desulfurization process device 5, and CO is converted into CO 2 and H 2 , and then divided into two parts, one part is directly carbonized by the carbonization device 6; 2 gas, via CO 2 The compressor 8 is pressurized to 0.8 MPa and then enters the carbonization device 6 together with the shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com