Ultrahigh-concentration beer brewing strain and culture medium for screening same

An ultra-high concentration, medium technology, applied in beer brewing, beer fermentation methods, fungi, etc., can solve problems such as difficult flavor, yeast autolysis, and cell morphology and cell activity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Breeding of ultra-high concentration yeast.

[0025] Randomly select three beer yeast strains from the brewery as the starting yeast strains to carry out mutagenesis through the above method. These three yeast strains are respectively: YJ, F, 36, and undergo the following selection steps:

[0026] 1. Activation of the starting strain

[0027] The bacteria were inoculated into the wort with the addition amount of 3%, and cultured on a shaker at 25°C for 24 hours until the logarithmic growth phase of the yeast, at which time the bacteria had the best vigor and were suitable for mutagenesis.

[0028] 2 Cell Suspension Preparation

[0029] Centrifuge the activated bacterial liquid at 3500r / min for 10min, collect the bacterial cells, wash once with sterilized normal saline, shake with a vortex mixer for 10min, count the number of bacterial cells with a hemocytometer, and then adjust the cell concentration with normal saline to make it become 10 6 cells / ml of bac...

Embodiment 2

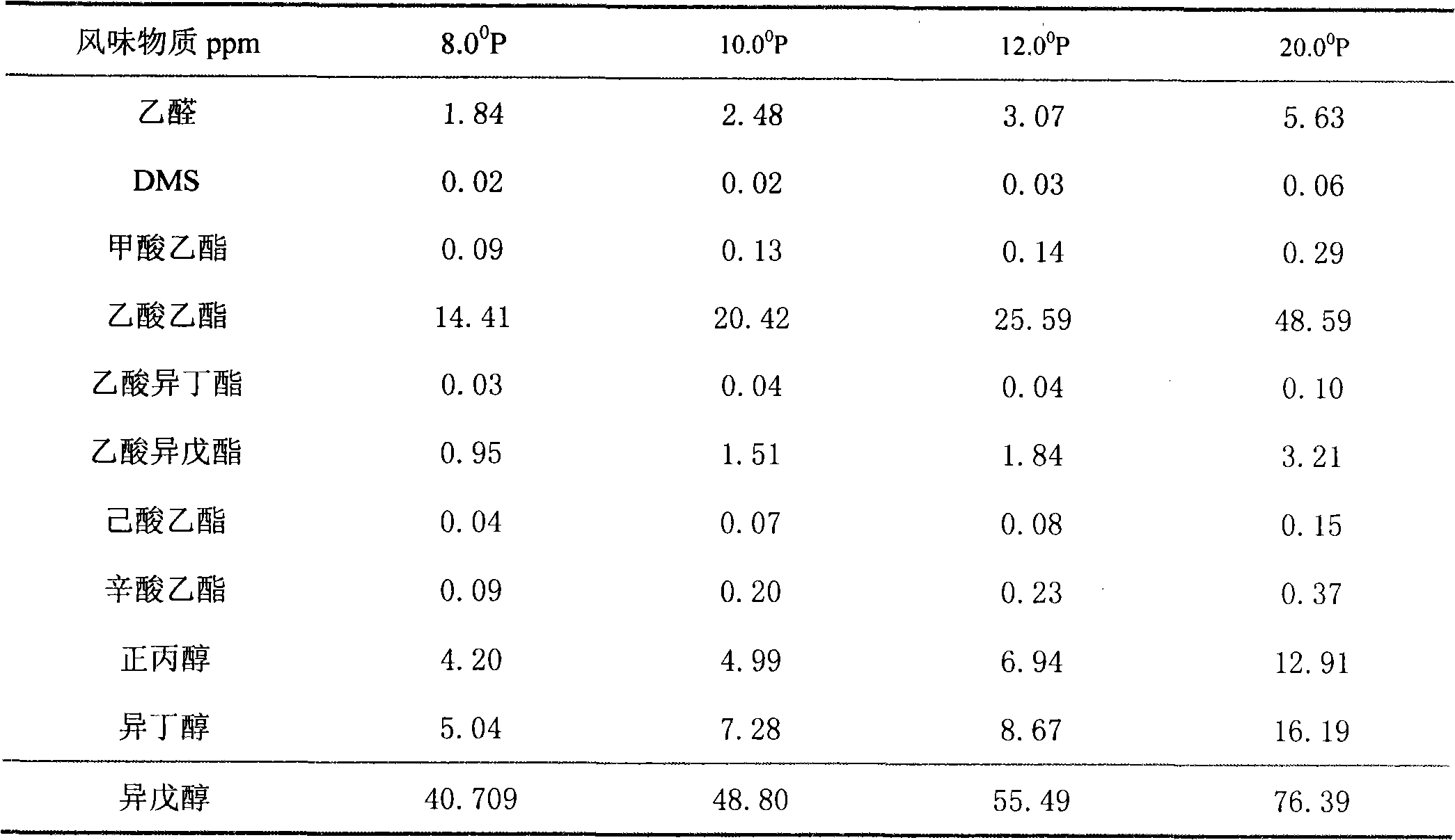

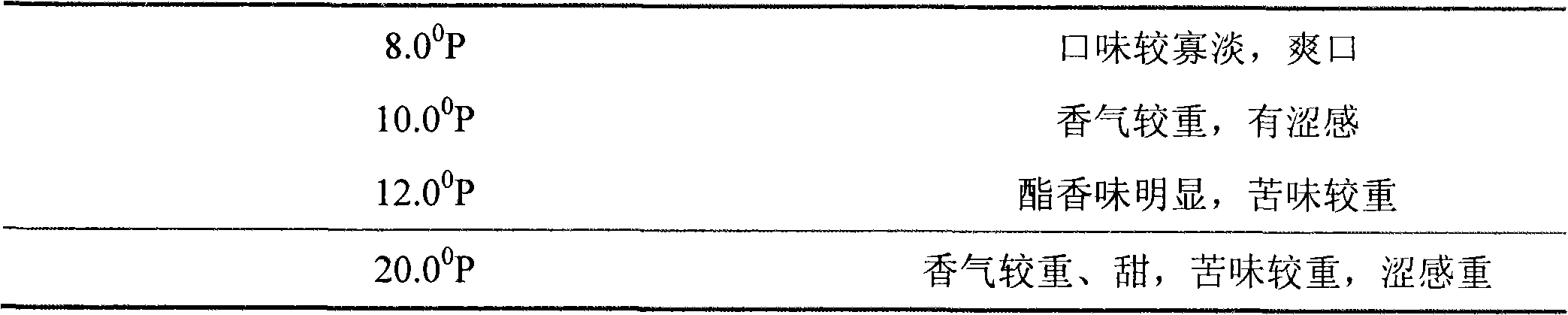

[0052] The fermentation of embodiment 2 ultra-high-strength beer

[0053] Use the above strains 1, 2, A, B to ferment through the following fermentation steps:

[0054] 1) Saccharification, using 60-70% malt and 30-40% rice to make the original wort with a concentration of 16°P, adding syrup to the boiling pot, and adjusting the concentration of the wort to 20°P;

[0055] 2) Fermentation, after the wort is cooled, the oxygenation amount is 10-12ppm, and the inoculum is inoculated, and the inoculation amount is controlled at 1.5-1.8*10 7 per ml, the fermentation temperature is 14°C, and the sugar content of the booster is controlled at 6-7°P;

[0056] 3) Dilution, the dilution ratio of the high-concentration dilution process is 80-100%.

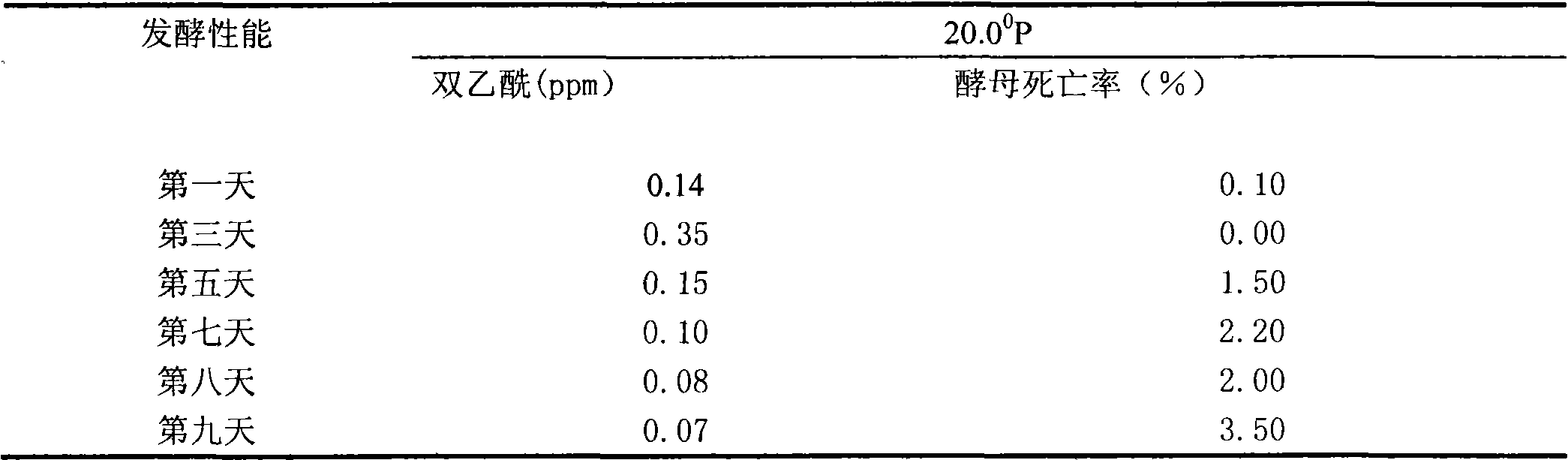

[0057] Fermentation performance index

[0058]

Embodiment 3

[0059] Embodiment 3 brewery implements

[0060] For a 200,000-ton brewery (all producing 12°P beer), if the ultra-high-concentration fermentation technology is adopted and the original wort concentration is 20°P, it can be compared with the traditional 12°P fermentation process without increasing equipment investment. Compared with that, the production capacity is increased by (20-12) / 12×100=75%, which greatly improves the equipment utilization rate and reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com