Nitrogen supplementing device of spandex spinning channel and process thereof

A technology of spinning tunnel and nitrogen, which is applied in the field of nitrogen supplementation device for spandex spinning tunnel, which can solve the problems of environmental pollution, high energy consumption of nitrogen, etc., achieve huge economic benefits, reduce the amount of waste gas evacuation, and reduce the consumption.

Active Publication Date: 2010-10-06

浙江四海氨纶纤维有限公司

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in actual production, in order to reduce the oxygen content in the recycled gas, it is necessary to consume a large amount of nitrogen for replacement, and the energy consumption for preparing nitrogen is very large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

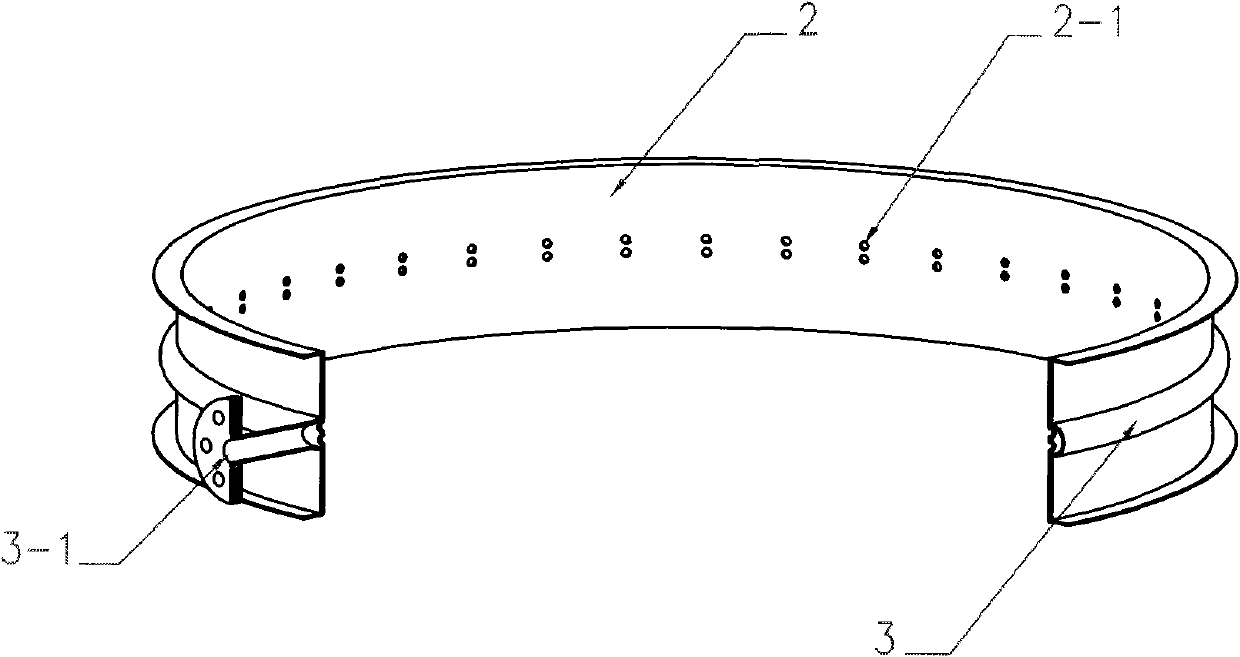

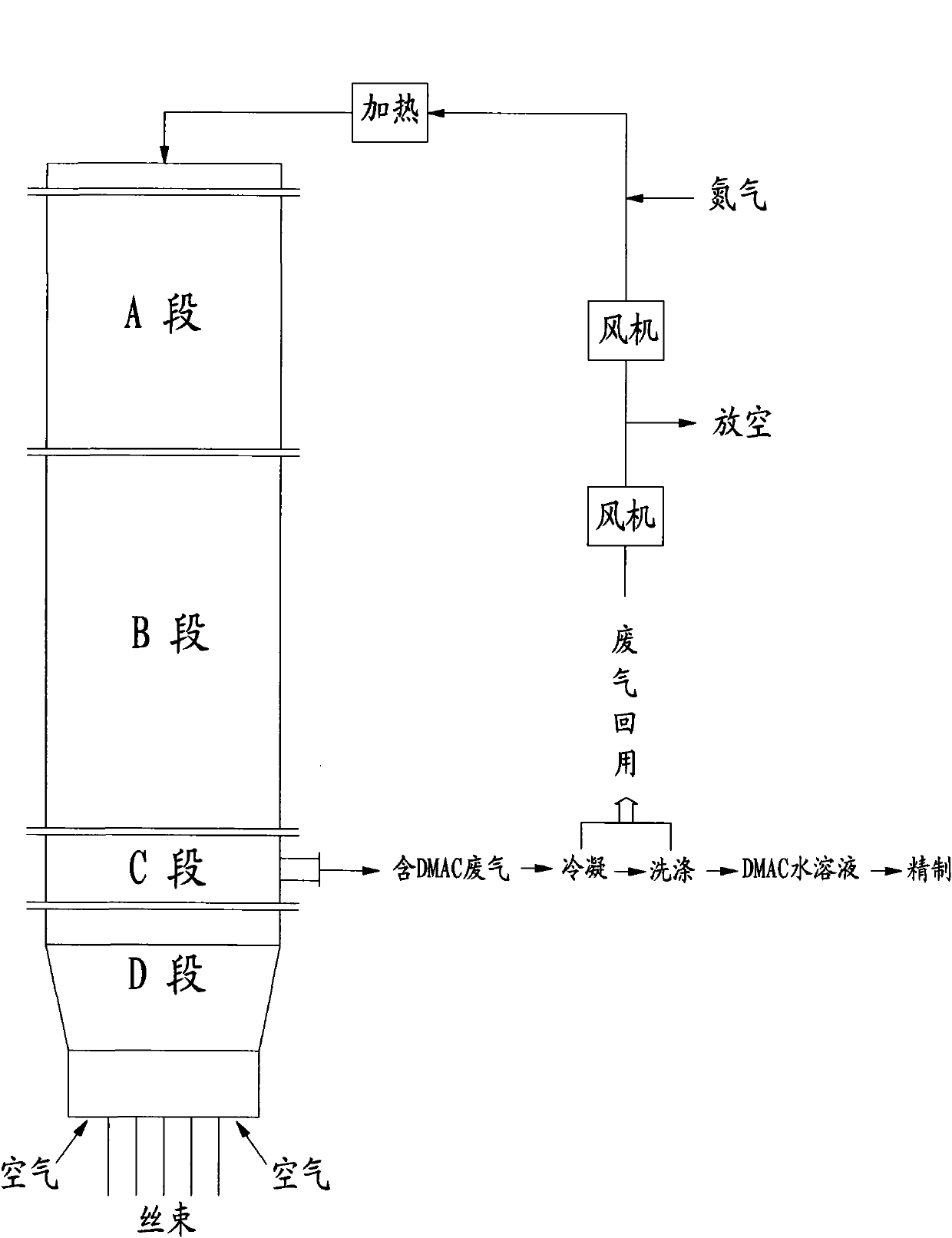

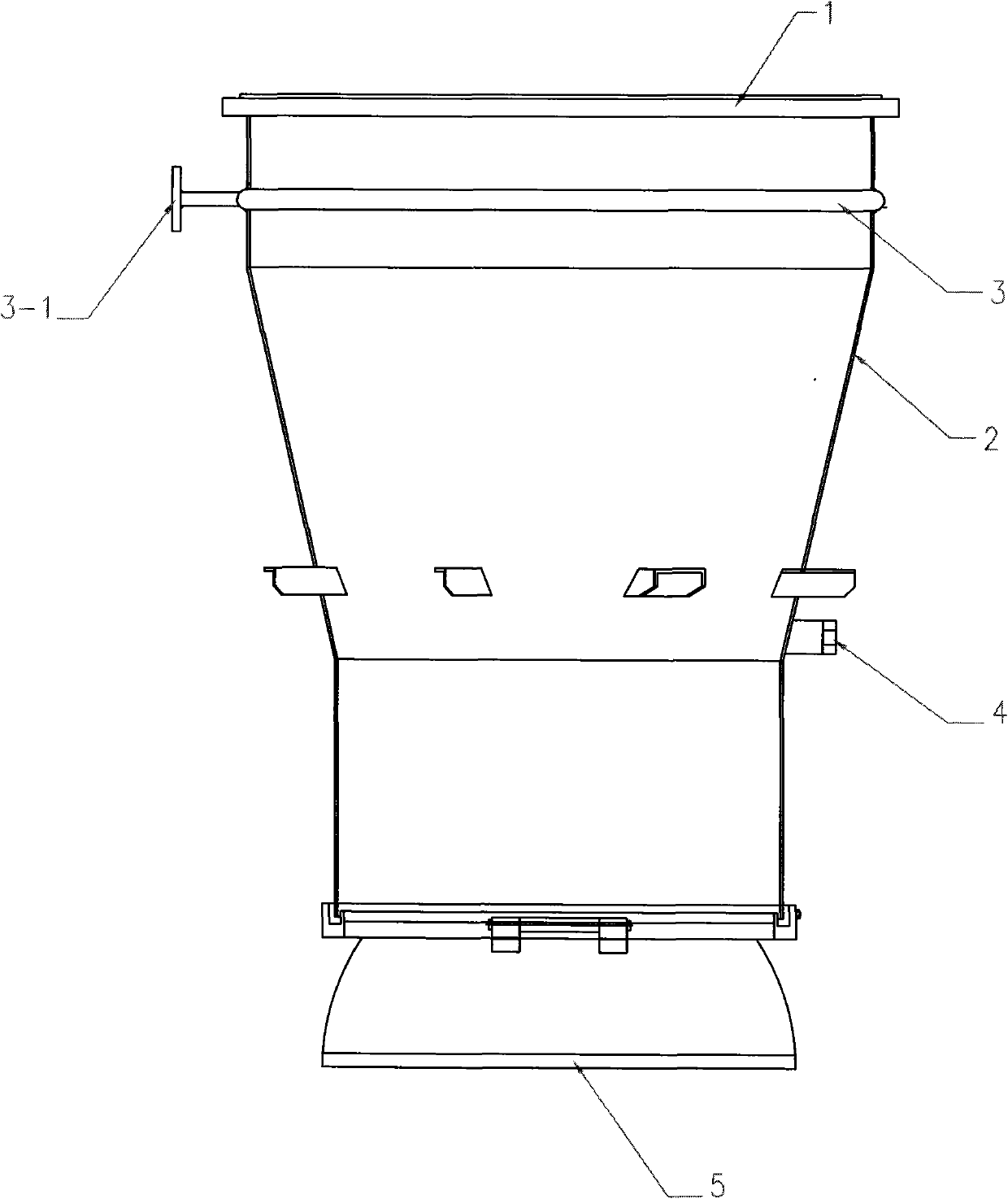

The invention discloses a nitrogen supplementing device of a spandex spinning channel and a process thereof, which reform the traditional Nisshinbo process, and adds a nitrogen supplementing procedure. A nitrogen supplementing device is additionally arranged at a section D of the spinning channel. Due to the filling of the nitrogen, the suction quantity of the air at the bottom of the shaft is reduced, the oxygen-containing quantity inside the shaft is reduced, the waste emission quantity is reduced, and the contents of harmful substances in the process of waste emission is reduced with consumption reduction, energy saving and enormous effect of low carbon environment protection. The nitrogen supplementing device comprises a channel cylinder, an annular pipe, a nitrogen inlet pipe and distributing holes, wherein an airtight annular channel is formed by the annular pipe and the shaft cylinder wall arranged on an outer wall of the shaft cylinder, and a cylinder wall encircled by the annular pipe is provided with a plurality of rows of distributing holes which are arranged along the circumference direction. The nitrogen is input from the nitrogen inlet pipe into the annular pipe, and enters the shaft cylinder through the distributing holes. Because the supplemented nitrogen uniformly inrushes at low pressure and low speed, the waving of tows cannot occur.

Description

technical field The invention relates to chemical fiber spinning equipment and a process thereof, in particular to a nitrogen supplementing device for a spandex spinning tunnel and a process thereof. Background technique The Nisshinbo dry spinning used by our company belongs to the more advanced spandex spinning process in the world today. The spandex yarn has unique advantages in heat resistance and elongation, and its silk quality is better, which has been generally recognized by users. The disadvantage is that the equipment investment is large, the nitrogen consumption is high, and the waste gas discharged from the spinning process contains a small amount of DMAC volatiles (DMAC has certain damage to the human liver). The traditional spandex production process is: the spinning stock solution containing DMAC solvent is accurately metered by a metering pump, spun from the spinning head, the DMAC solvent evaporates in the spinning tunnel, and the polymer is cooled at a cert...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D5/04D01D10/00

Inventor 林红卫

Owner 浙江四海氨纶纤维有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com