Orthotropic alternatively laminated composite damping material and damping modulation method thereof

A composite damping material, orthotropic technology, applied in the field of composite damping materials, to achieve the effect of improved structural damping value, strong designability, and light and thin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

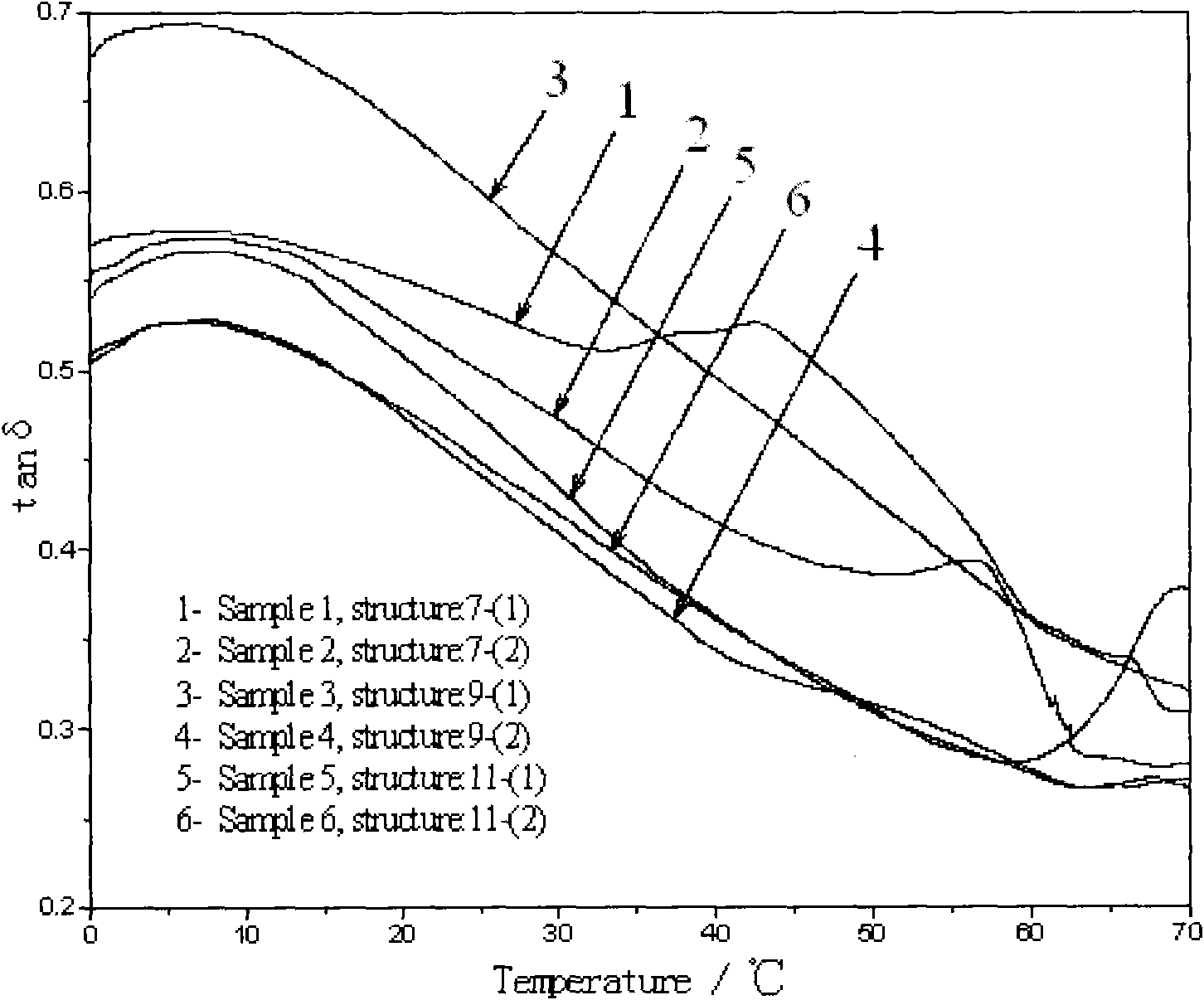

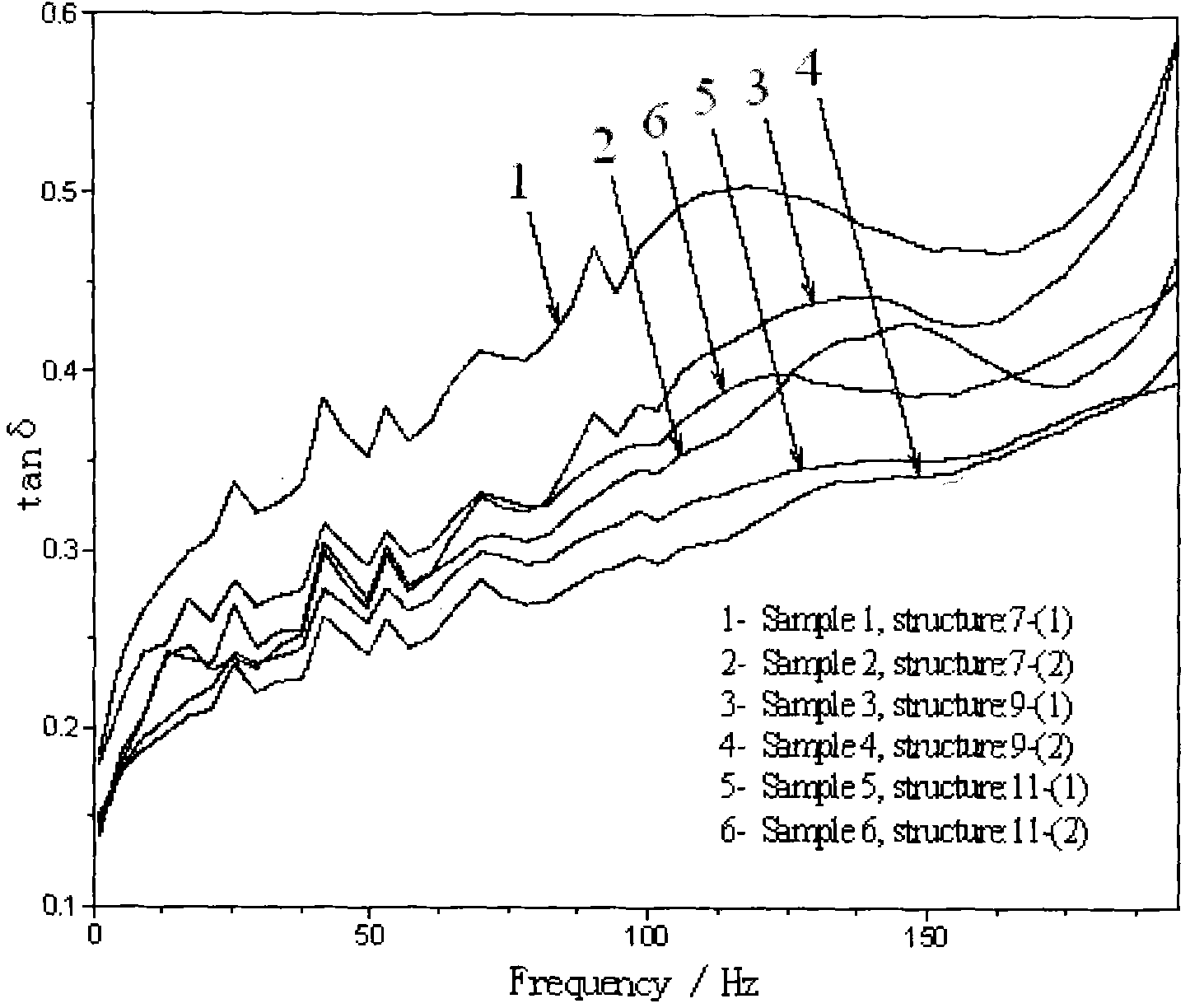

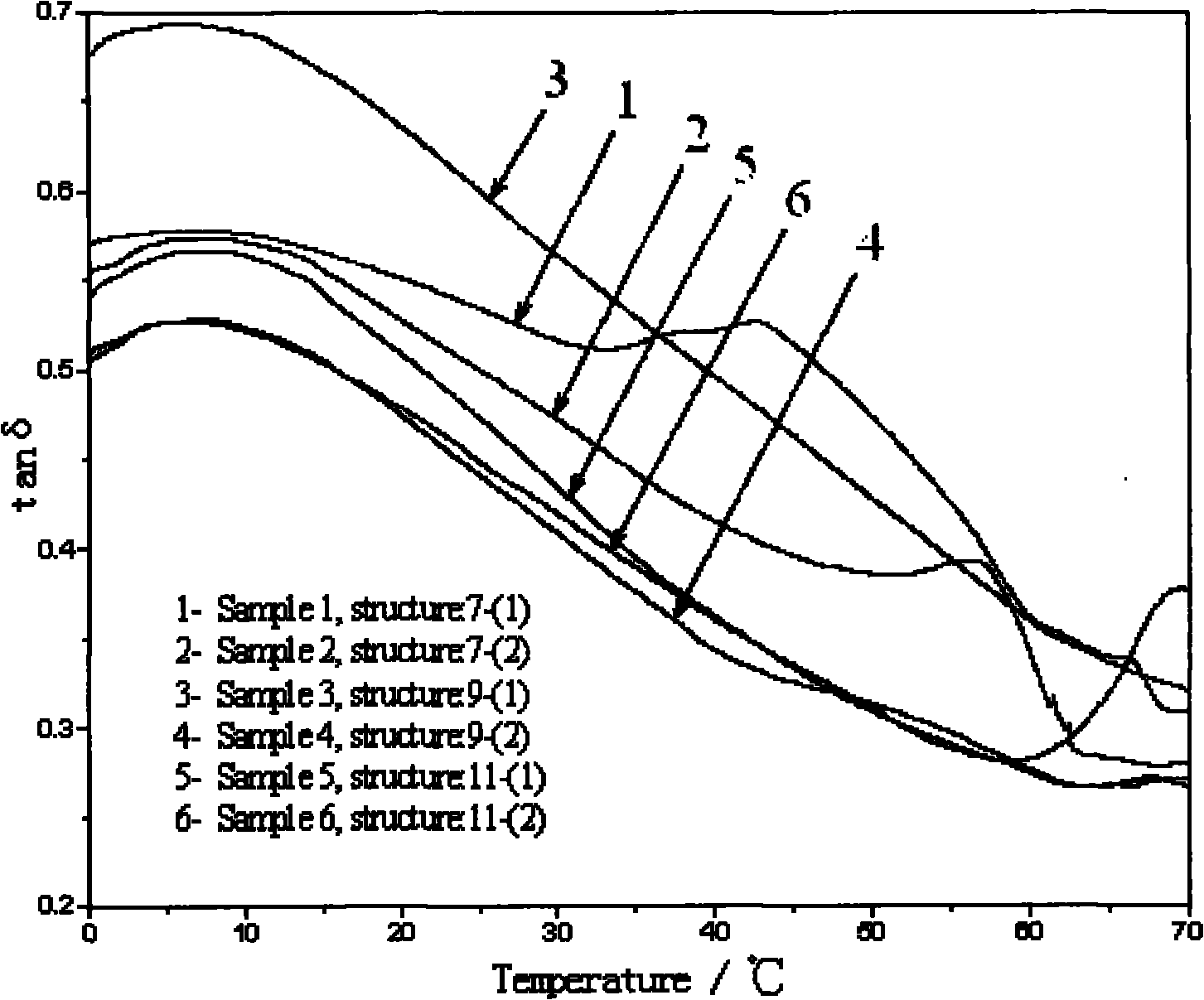

[0011] Example: 7 layers (3 damping layers 4 anisotropic layers) composite damping structural material

[0012] The specific structure is 0°(0.125) / 0.4 / 90°(0.075) / 0.3 / 90°(0.125) / 0.3 / 0°(0.125), and the structure representation is as follows: the anisotropic layer shows the fiber laying direction angle and thickness (in brackets), the damping layer only shows the thickness (in mm), and the layers are separated by the symbol " / ".

[0013] Raw materials:

[0014] The damping layer material of the test piece is made of pressure-sensitive viscoelastic damping material ZN-8 (domestic) with an interpenetrating network (IPN) structure, and the thickness is 0.3mm and 0.4mm. The material of the bonding layer is T54 / T60 modified epoxy resin for ships diluted with xylene (produced by Qingdao Ocean Chemical Research Institute of the Ministry of Chemical Industry, component ratio A:B=16:1). The anisotropic layer material is made of carbon fiber prepreg (produced in Shandong) scrape-coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com