Alcohol-soluble printing ink and preparation method thereof

A printing ink and alcohol-soluble technology, which is applied in the field of alcohol-soluble printing ink and its preparation, can solve the problems that water-based printing ink has not yet been industrialized, and achieve the effects of easy cleaning, easy availability of raw materials, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

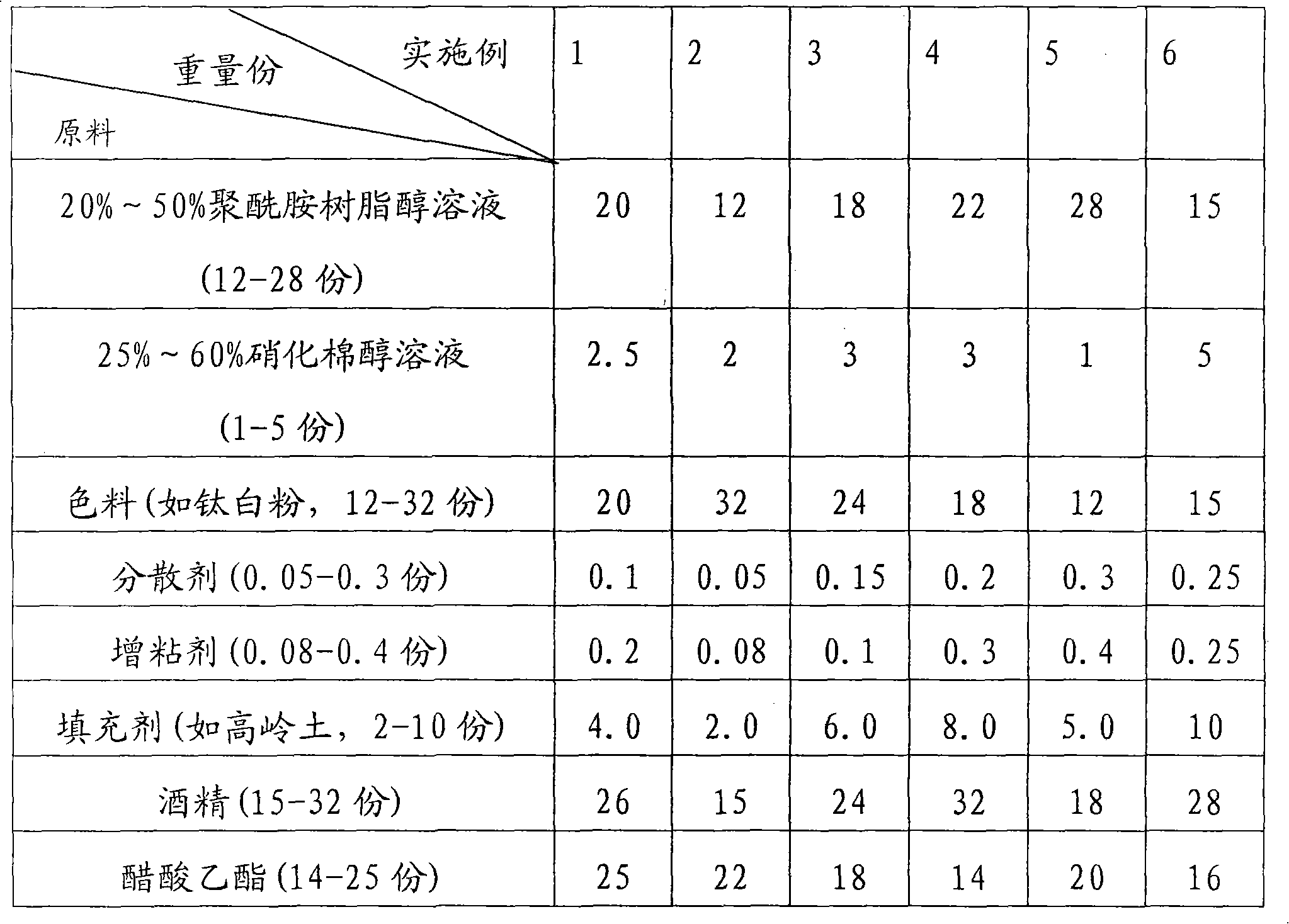

[0022] As shown in Table 1, 20 parts of 35% polyamide resin alcohol solution and 2.5 parts of 45% nitrogossy alcohol solution were prepared with ethanol, and 20 parts of pigment (titanium dioxide), 0.1 part of dispersant, and tackifier were added. 0.2 parts of filler and 4.0 parts of filler (kaolin), stir well in the container, and take 5 / 6 of the measured amount of alcohol solvent: 26 parts of ethanol and 25 parts of ethyl acetate, and add them to the container to adjust the viscosity of the mixture. And mix uniformly, then disperse in a high-speed disperser for 30 minutes at high speed, transfer to a sand mill to grind to a particle size of less than 20μm, and then transfer the mixture to a high-speed disperser for high-speed dispersion for 10 minutes to obtain alcohol-soluble white ink, sample for inspection , Its fineness is 20μm, viscosity is 25s (20℃, 4 cups), adhesion is 100%, solid content is 25.3%, pH=8.5, color fastness ≥6 grade, pure white color.

Embodiment 2

[0024] As shown in Table 1, 12 parts of 50% polyamide resin alcohol solution and 2 parts of 45% nitrosospinal alcohol solution were prepared with isopropanol, and 32 parts of colorant (golden red), 0.05 part of dispersant, 0.08 parts of thickener, 2.0 parts of filler (heavy calcium carbonate), stir well in the container, take the measured amount of 5 / 6 alcohol solvent 15 parts of ethanol and 22 parts of ethyl acetate, add them to the container to adjust the mixing The viscosity of the material is mixed uniformly, and then dispersed in a high-speed disperser for 30 minutes at high speed, transferred to a sand mill to grind to a particle size of less than 12μm, and then transferred to the high-speed disperser for high-speed dispersion for 12 minutes to obtain alcohol solubility The red ink is sampled and tested. The fineness is 12μm. Take 1 / 6 of the remaining amount of the alcohol solvent, that is, 2.5 parts of ethanol and 3.7 parts of ethyl acetate to rinse the container. After m...

Embodiment 3

[0026] As shown in Table 1, 18 parts of 32% polyamide resin alcohol solution and 3 parts of 28% nitrogossy alcohol solution were prepared with ethanol. 24 parts of colorant (permanent yellow), 0.15 part of dispersant, and Viscosity 0.1 part, filler (kaolin) 6.0 parts, stir evenly in the container, take 5 / 6 of the measured amount of alcohol solvent: 24 parts of ethanol, 18 parts of ethyl acetate, add to the container to adjust the viscosity of the mixture, And mix uniformly, then disperse in a high-speed disperser for 25 minutes at high speed, transfer to a sand mill to grind to a particle size of less than 10μm, and then transfer the mixture to a high-speed disperser for high-speed dispersion for 14 minutes to obtain alcohol-soluble yellow ink, sample Inspection shows that its fineness is 11μm, viscosity is 24s (25°C, coating 4 cups), adhesion is 100%, solid content is 26%, pH=9.5, color fastness ≥6, and color is yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com