Bast fiber degumming preprocessor and bast fiber degumming preprocessing method

A technology of bast fiber and pretreatment machine, which is applied in the direction of fiber treatment, chemical post-treatment of fiber, and production of bast fiber by chemical method, which can solve the problem of high cost of degumming agent and equipment investment, unfavorable large-scale production, and enzyme activity rate Higher requirements and other issues, to achieve the effect of reducing the consumption of coal electricity and degumming agent, reducing the degumming treatment time, and shortening the treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

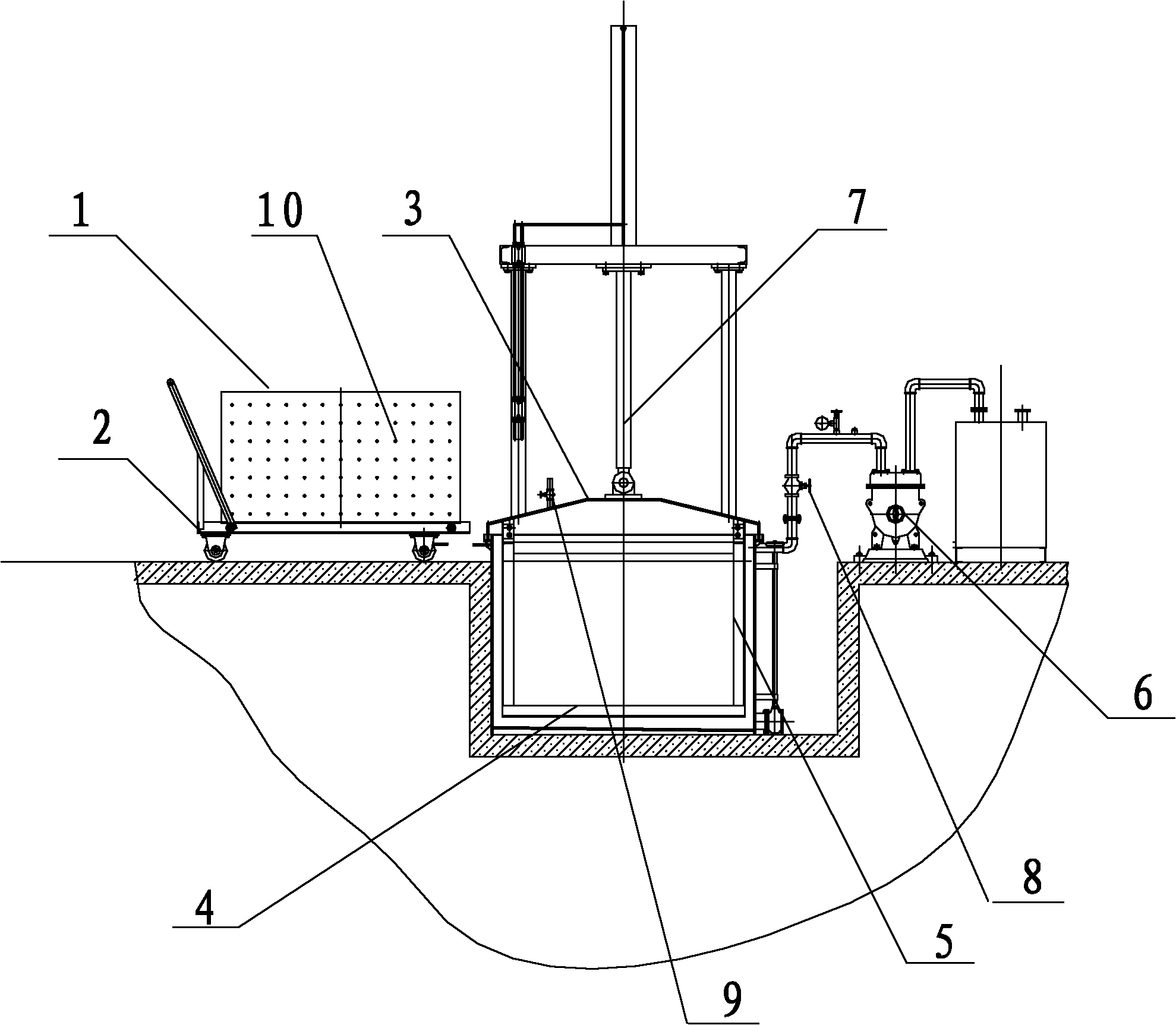

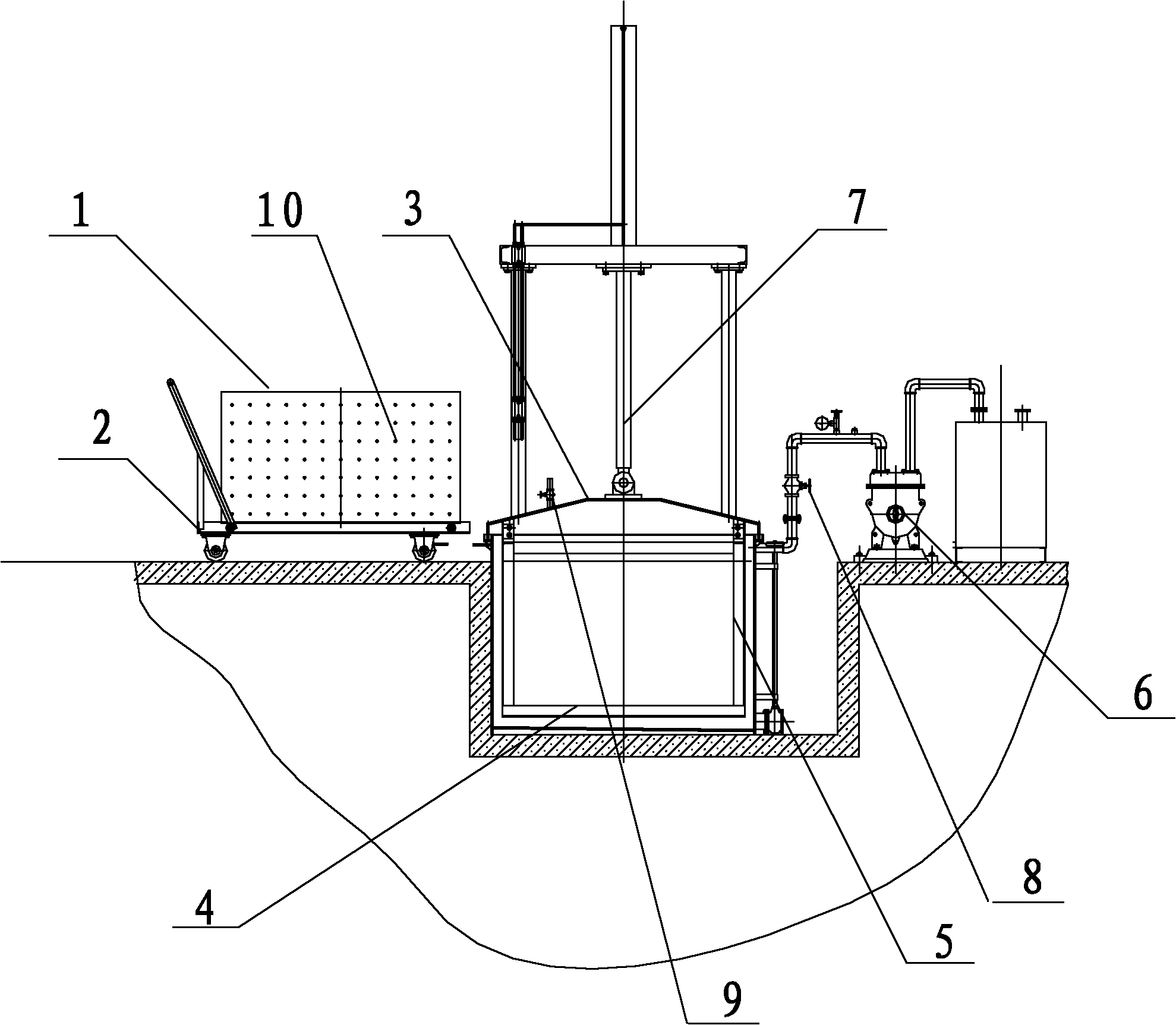

[0014] Such as figure 1 As shown, the bast fiber degumming pretreatment machine of the present invention comprises material box 1, machine cylinder 5, airtight machine cover 3, is provided with air valve 9 on airtight machine cover 3, is fixed on the electric hydraulic lifting device 7 above airtight machine cover 3 , the bottom of the airtight machine cover 3 is fixed with a material box frame 4, and the box wall of the material box 1 is provided with an eyelet 10, and the upper part of the material box can be opened for putting in and taking out raw materials; Vacuum pump 6 is installed, and pipeline is installed on the vacuum pump 6 and leads in the machine cylinder 5, has steam pipeline to lead into machine cylinder 5 outside machine cylinder 5, and steam valve 8 is installed on the steam pipeline. The device is made of stainless steel or other corrosion-resistant materials. The machine cylinder 5 is installed in the machine pit, and the machine edge is flush with the gro...

Embodiment 2

[0020] The bast fiber degumming pretreatment machine of this embodiment is the same as embodiment one, and the bast fiber degumming pretreatment method comprises the following steps:

[0021] 1) Put the ramie raw material into the material box 1, then put the material box 1 on the trolley 2, open the electro-hydraulic lifting device 7, raise the airtight cover 3 to the upper limit and stop the machine, and put it into the cylinder 5 at a temperature of 40C° , bath ratio 1: 3, pH value 3.5 by oxalic acid 1g / L and surfactant polyoxyethylene ether 1g / L preparation raw material treatment liquid, feed box 1 is pushed on the feed box frame 4 with trolley 2, Start the electro-hydraulic lifting device 7, close the airtight machine cover 3, make the machine cylinder 5 form an airtight machine cylinder, immerse the raw material in the material box 1 in the raw material treatment liquid, open the steam valve 8, feed steam for 25 minutes and keep the temperature at 40°C;

[0022] 2) Close...

Embodiment 3

[0025] The bast fiber degumming pretreatment machine of this embodiment is the same as embodiment one, and the bast fiber degumming pretreatment method comprises the following steps:

[0026] 1) Put the sisal raw material into the material box 1, then put the material box 1 on the trolley 2, open the electro-hydraulic lifting device 7, raise the airtight cover 3 to the upper limit and stop the machine, put the temperature in the cylinder 5 to 45C °, bath ratio 1:3, pH value 4 raw material treatment solution prepared by oxalic acid 2.2g / L and surfactant polyoxyethylene ether 2g / L, use trolley 2 to push material box 1 into material box frame 4 On, start the electro-hydraulic lifting device 7, close the airtight machine cover 3, make the machine cylinder 5 form an airtight machine cylinder, immerse the raw material in the material box 1 in the raw material processing liquid, open the steam valve 8, and pass in steam for 30 minutes to keep the temperature at 45°C ;

[0027] 2) Cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com