High-voltage side mutual inductance energy-acquiring device of high-voltage power transmission line

A high-voltage transmission line, mutual inductance energy harvesting technology, applied in the direction of circuit devices, output power conversion devices, circuits, etc., can solve the problems of difficult on-site maintenance, expensive laser source, low precision and accuracy of DC power supply, etc., to achieve Highly Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in more detail.

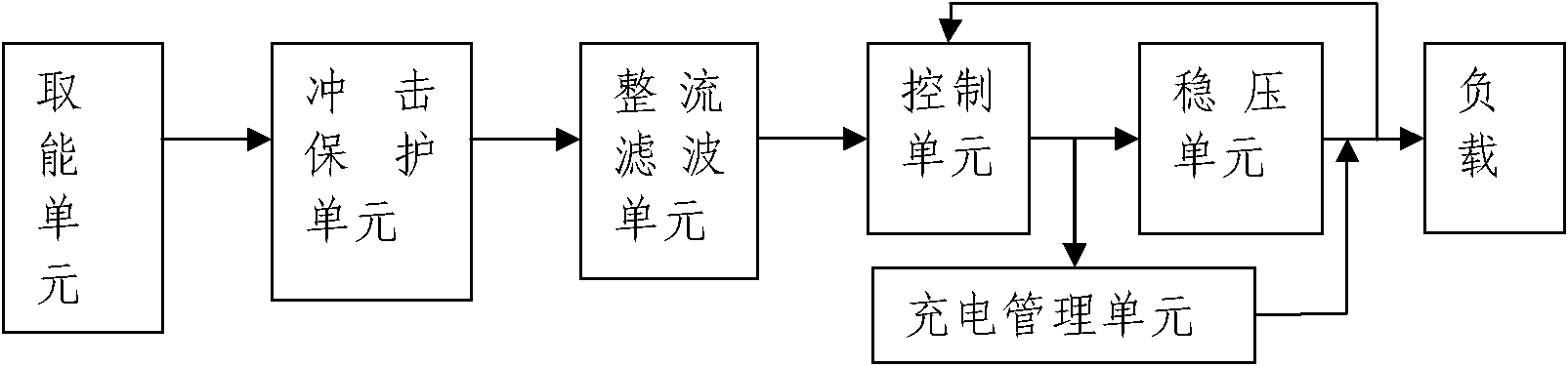

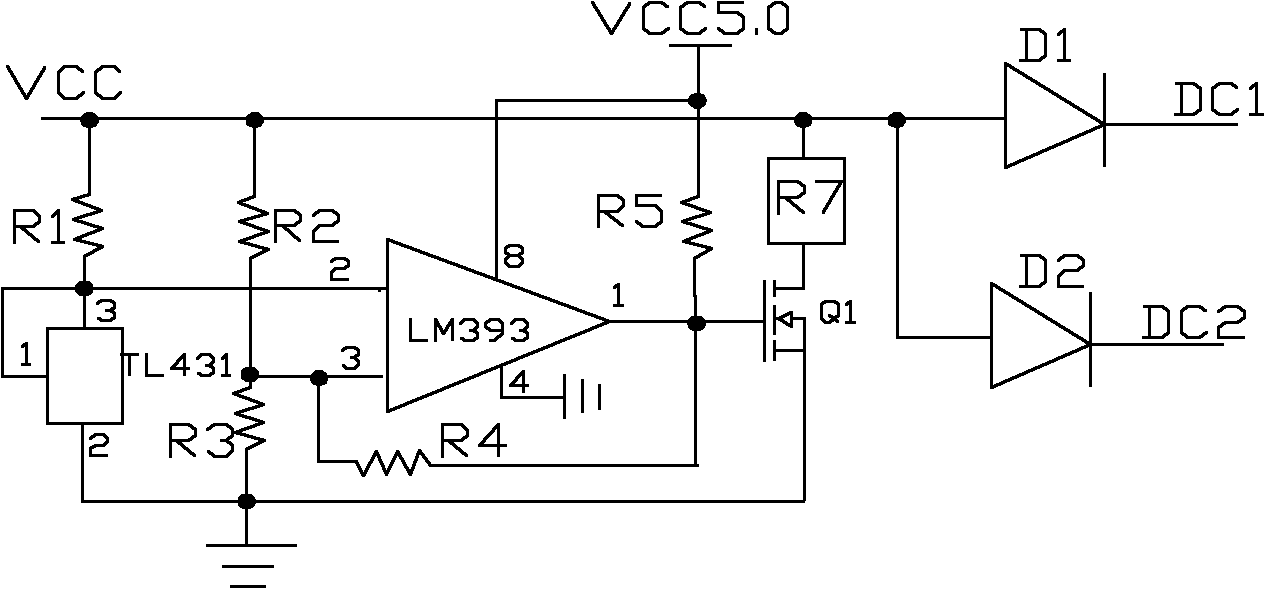

[0018] The present invention is composed of an energy-taking unit (mainly composed of an iron core (U-shaped or O-shaped) with an air gap and a coil), an impact protection circuit, a filter rectifier circuit, a control unit circuit, a voltage stabilizing circuit, a charging management circuit and load composition. Its specific circuit connection is mainly to handle the coordination relationship of the control, voltage stabilization, and lithium battery charging management circuits.

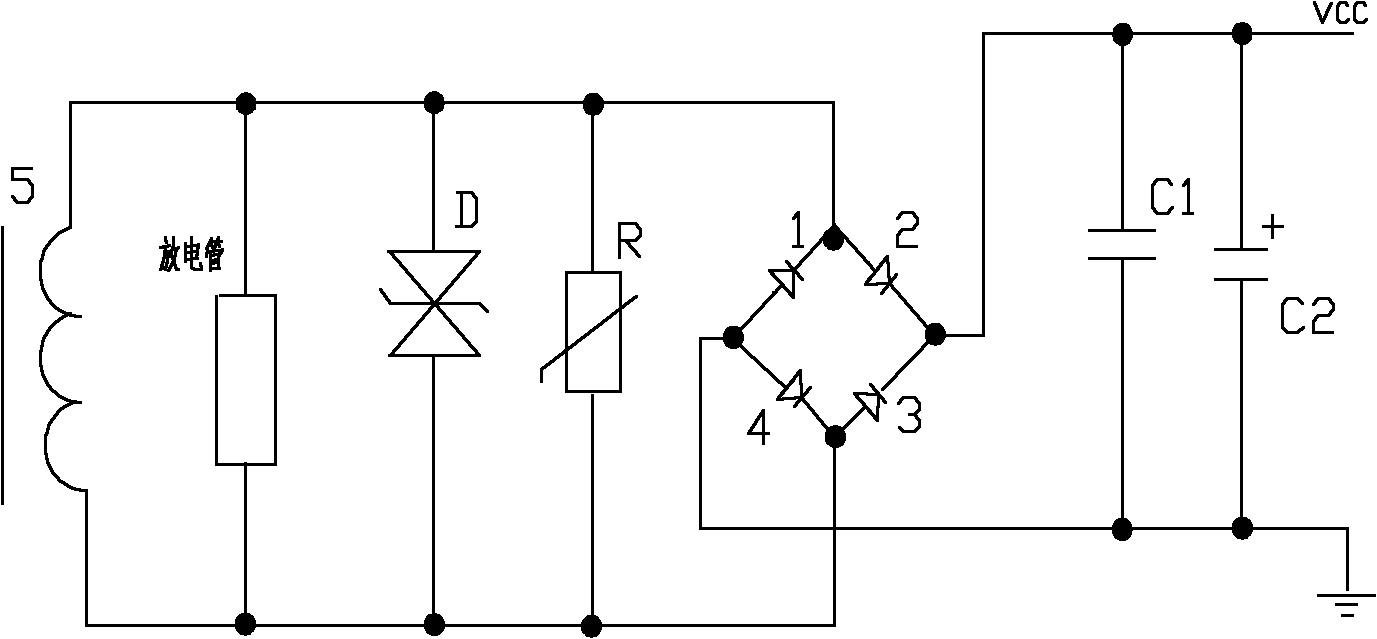

[0019] In the front part of the present invention, the iron core wound with enameled wire (that is, the composed coil) is placed on the high-voltage transmission line, so that the induced electromotive force is obtained at both ends of the coil. A bidirectional gas discharge tube, a bidirectional transient suppression diode (TVS) D and an adjustable varistor R are connected in parallel at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com