Simulation method of upflow biological hydrogen production reactor flow field

A technology of biological hydrogen production and simulation method, which is applied in the fields of instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as unfavorable mass transfer and biological fermentation degradation, achieve convenient design and optimization, save time and cost, Avoid blindness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

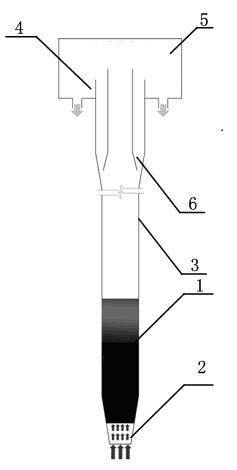

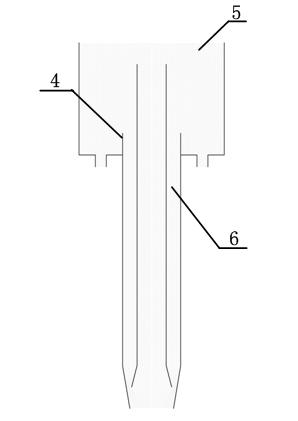

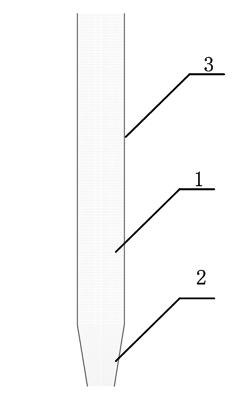

[0018] Specific implementation mode one, to combine figure 1 and figure 2 In this embodiment, the method for simulating the flow field of an upflow biohydrogen production reactor is a simulation of an upflow biohydrogen production reactor. The upflow biohydrogen production reactor consists of a reaction zone 1, a water inlet zone 2. The side wall 3, the overflow tank 4, the gas collection area 5 and the three-phase separation area 6 are composed, the side wall 3 is a cylindrical hollow body, the bottom of the side wall 3 is the water inlet area 2, and the water inlet area 2 The bottom is provided with a water inlet, the reaction zone 1 is inside the side wall 3 and is set above the water inlet zone 2, and the three-phase separation zone 6 is set inside the side wall 3 and on the upper part of the side wall 3, above the three-phase separation zone 6 A gas collection area 5 is provided, and the three-phase separation area 6 communicates with the gas collection area 5. An ove...

specific Embodiment approach 2

[0028] Specific implementation mode two, to combine figure 2 Describe this embodiment. This embodiment is a further description of Step 1 in Embodiment 1. In Step 1, the grid unit is a quadrilateral grid unit, and the influent area 2 and the three-phase separation area 6 are dense grids.

[0029] That is, the grids of the water inlet area 2 and the three-phase separation area 6 are denser than those of the reaction area 1 , the overflow tank 4 and the gas collection area 5 .

specific Embodiment approach 3

[0030] Specific implementation mode three, This embodiment is a further description of Step 2 in Embodiment 1. In Step 2, a two-dimensional computational domain Eulerian-Eulerian three-phase fluid model of the upflow biohydrogen production reactor profile is established to obtain the mass conservation equation and momentum Conservation equation, specifically:

[0031] Wastewater is a continuous flow of liquid phase, sludge is a continuous flow of solid phase, and fermentation gas is a continuous flow of gaseous phase; the three-phase continuous flow of gas, liquid, and solid shares the pressure field according to their respective volume fractions; the movement of each phase is determined by its corresponding The momentum conservation equation and mass conservation equation control;

[0032] The mass conservation equations of each phase, that is, the continuity equation, are as follows:

[0033] The mass conservation equation for the liquid phase is: ;

[0034] The mass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com