Process for de-coloring feather/feather meal degradation product and application of de-colored product

A technology of degradation products and feather powder, applied in applications, animal feed, animal feed, etc., can solve the problems of poor palatability of feed, water pollution, black appearance, etc., achieve the effect of removing bitterness, simple process, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation process of feather or feather meal degradation product is:

[0018] Prepare feather or feather meal degradation product by alkaline hydrolysis alone: add feather or commercially available feather meal to alkali solution with a mass concentration of 3% or less according to the ratio of 20% (according to mass / volume; g / ml) to the alkali solution, 30- Shake and degrade in a water bath at 90°C for 5-6 hours, centrifuge at 5000rpm for 10 minutes, collect the supernatant containing soluble protein, which is the feather powder alkaline hydrolysis solution, that is, the alkaline hydrolysis method to prepare feathers or feather meal degradation products;

[0019] Separate enzymatic hydrolysis method to prepare feather or feather meal degradation products: feather or commercially available feather meal, add single protease or compound protease at a mass ratio of 1 / 100-1 / 200, and add 20% (according to mass / volume; g / ml) Next, add distilled water to adjust the pH ...

Embodiment 1

[0033] 1. Take 500mL feather powder alkaline hydrolyzate, and slowly adjust its pH to 6.0 with 0.5mol / L sulfuric acid solution. Centrifuge at 5000rpm for 10min to collect the precipitate.

[0034] 2. Continue to slowly adjust the pH of the centrifuged supernatant in step 1 to 4.0 with 0.5 mol / L sulfuric acid solution. Centrifuge at 5000rpm for 10min to collect the precipitate.

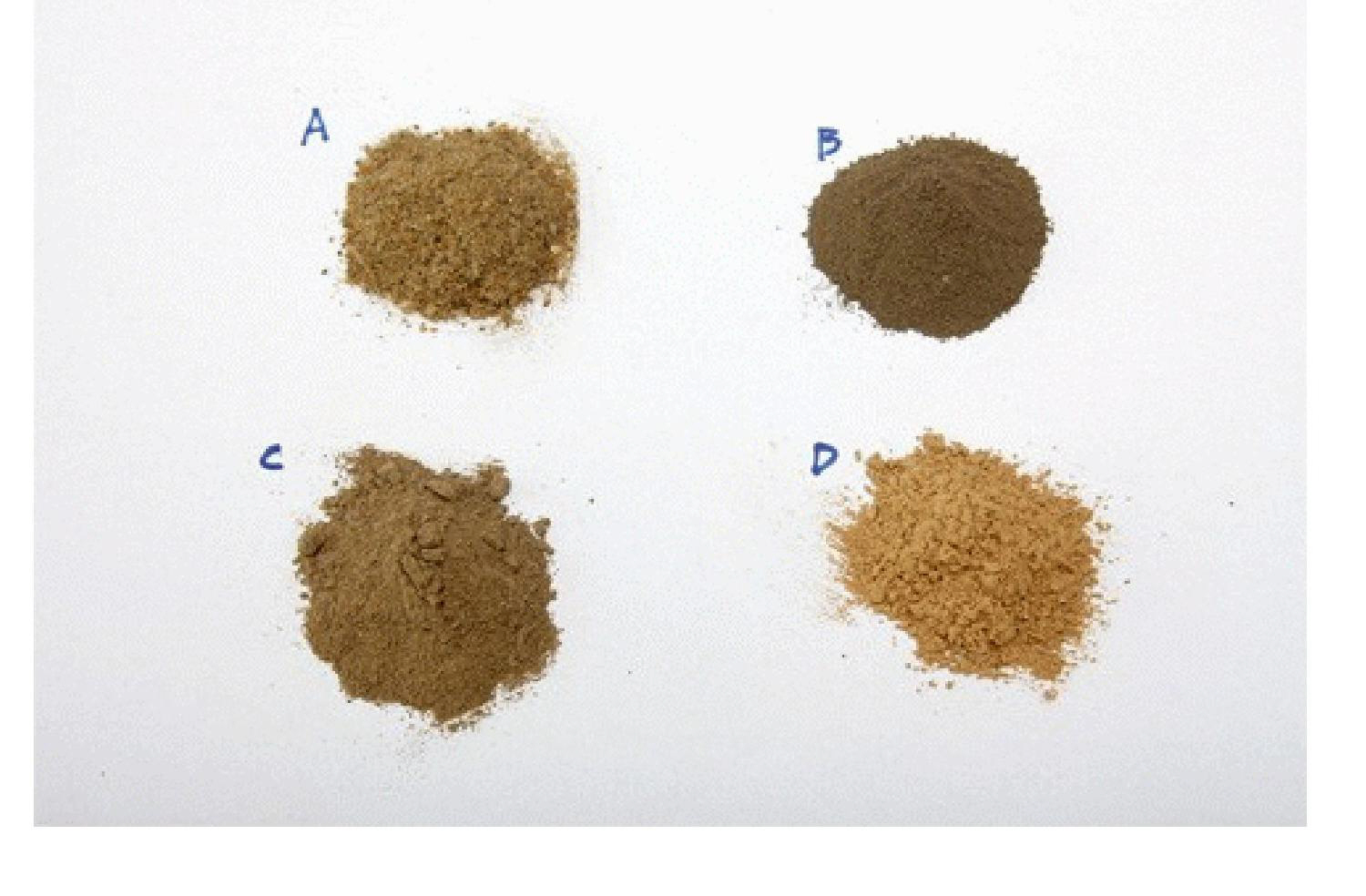

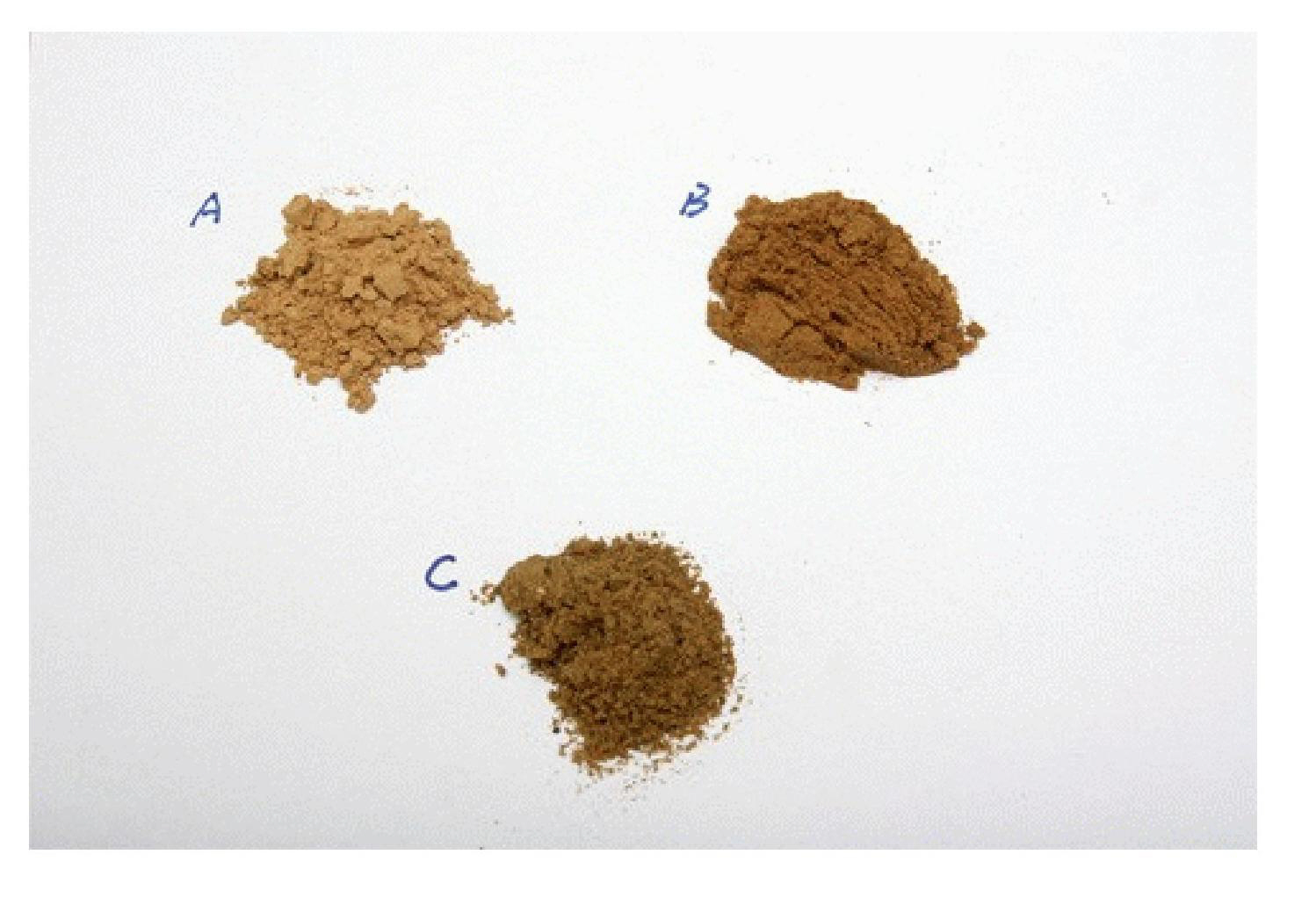

[0035] 3. Dry the two precipitates separately at 70°C.

[0036] 4. Use the cyclone mill to crush the dried samples into powder to obtain different grades of finished products.

Embodiment 2

[0038] 1. Take 500mL of feather powder enzymatic hydrolysis solution, and slowly adjust its pH to 6.0 with 0.5mol / L sulfuric acid solution. Centrifuge at 5000rpm for 10min to collect the precipitate.

[0039] 2. Continue to slowly adjust the pH of the centrifuged supernatant in step 1 to 4.0 with 0.5 mol / L sulfuric acid solution. Centrifuge at 5000rpm for 10min to collect the precipitate.

[0040] 3. Precipitate the two parts separately and dry them at 70°C.

[0041] 4. Use the cyclone mill to crush the dried samples into powder to obtain different grades of finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com