Treatment method of stainless steel pickling waste water

A technology for pickling wastewater and a treatment method, which is applied in the field of chemical treatment to achieve the effects of reducing treatment costs, not increasing equipment investment, and achieving good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

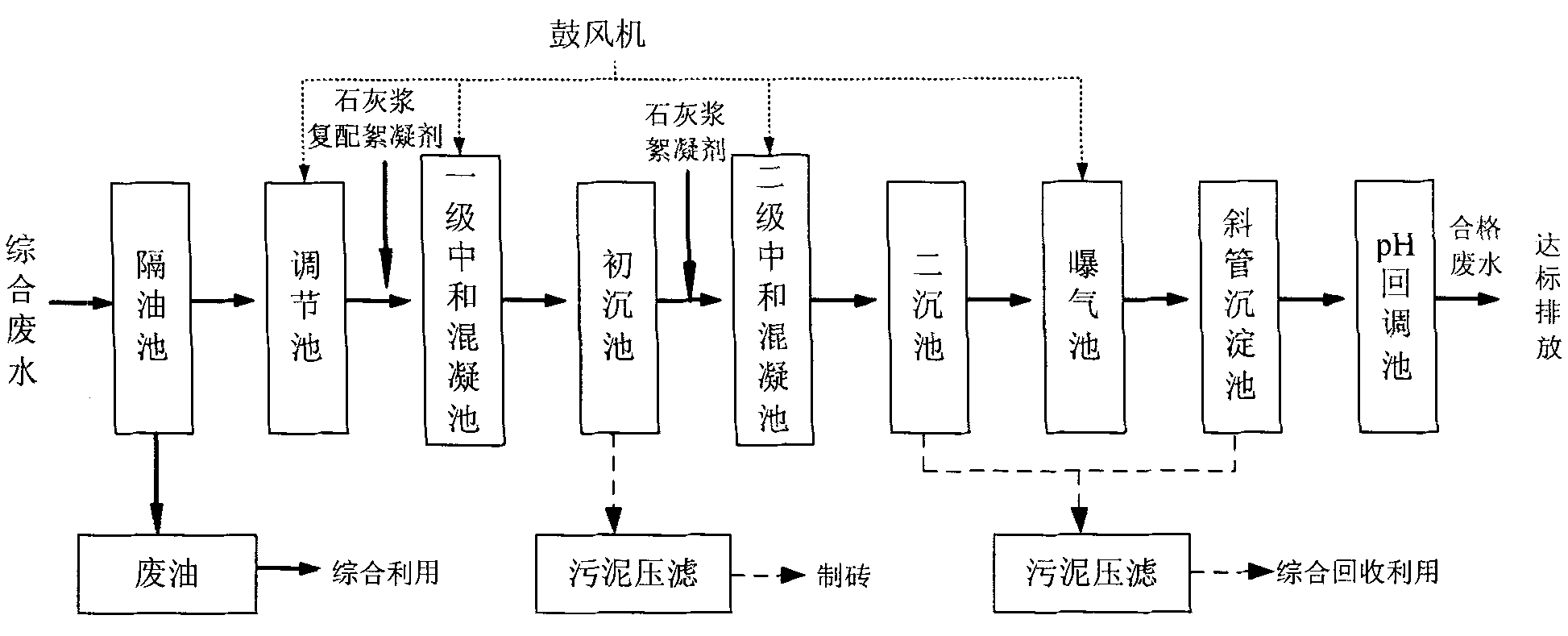

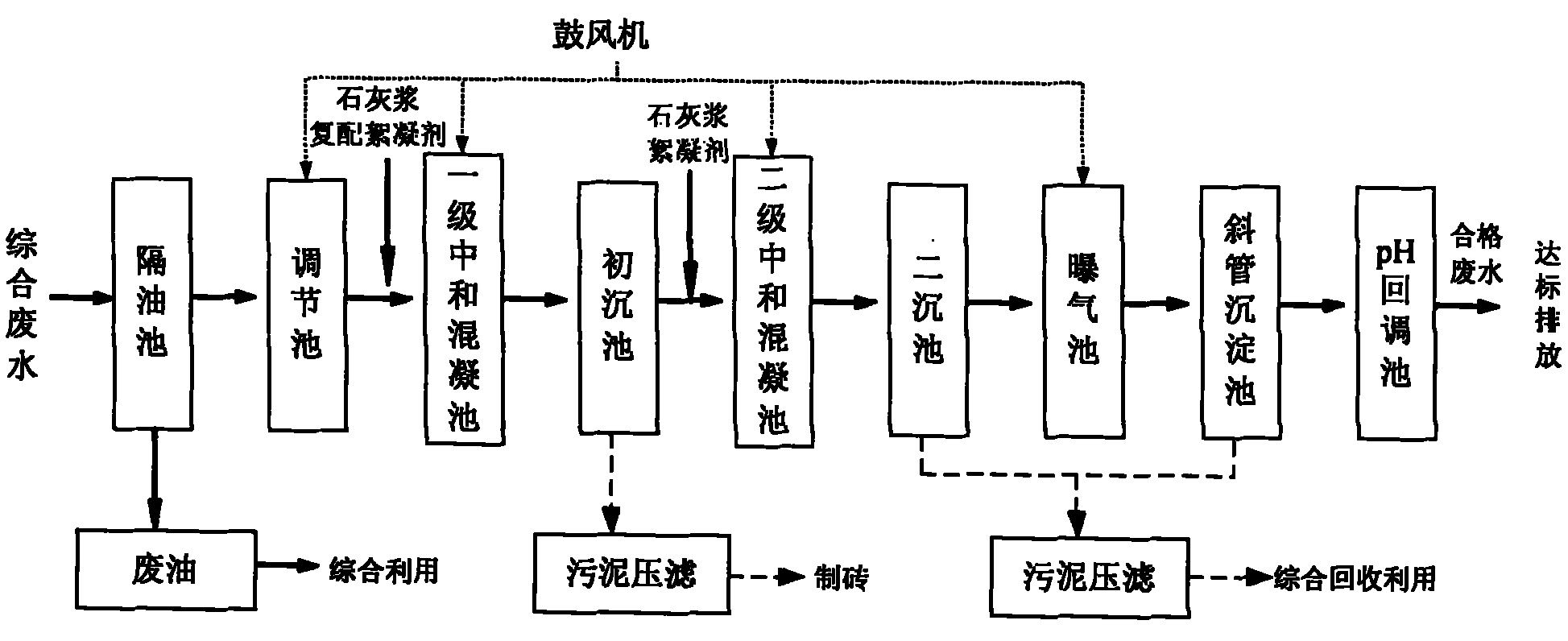

Method used

Image

Examples

Embodiment 1

[0036] The 100 tons of pickling wastewater collected, the stainless steel acid wastewater that entered the comprehensive wastewater treatment station, was sent to the grease trap to remove the oil in the wastewater; then it flowed into the adjustment pool and stayed in the adjustment pool for 6 hours; The waste water is sent to the primary neutralization coagulation tank, and lime milk is added to the tank, and the amount of lime milk used is 650kg; and the amount of compound flocculant is 2-3kg (the ratio of PAM cationic flocculant: non-ionic flocculant is 2 : 1), then adjust the pH of the waste water to 3.6; send the waste water into the pre-sedimentation tank, carry out natural settlement treatment, press filter to remove suspended solids and sand in the waste water; generate about 2.8 tons of sludge in total, of which the priceless waste 1.3 tons of mud (nickel dry basis content 2 , adjust the pH to 9.5, and then add 1kg of PAM non-ionic flocculant to generate alum flowers;...

Embodiment 2

[0038] In the same steps as in the embodiment, the collected 100 tons of pickling waste water is removed in the grease trap to remove the oil in the waste water; then stay in the regulating pond for 4 hours; the regulated waste water is sent to the first-level neutralization coagulation pond , add lime milk to the pool, the amount of lime milk used is 680kg; and the amount of compound flocculant is 2-3kg (the ratio of PAM cationic flocculant: non-ionic flocculant is 1: 1), and then adjust the pH of wastewater to 3.9; then send the wastewater into the pre-sedimentation tank for natural sedimentation treatment, press filtration to remove suspended solids and sand in the wastewater; a total of about 2.7 tons of sludge is produced, of which 1.4 tons of priceless sludge (nickel dry basis content 2 , the pH to 9.7, and then add 1.4kg of PAM non-ionic flocculant to generate alum flowers; then enter the secondary settling tank, and then remove iron, chromium, nickel, etc. ~1.6 tons (ni...

Embodiment 3

[0040] In the same steps as in the embodiment, the collected 100 tons of pickling waste water is removed in the grease trap to remove the oil in the waste water; then stay in the regulating pond for 5 hours; the regulated waste water is sent to the primary neutralization coagulation pond , add milk of lime to the pond, the amount of milk of lime used is 600kg; and the amount of compound flocculant is 3.5kg (the ratio of PAM cationic flocculant: non-ionic flocculant is 1: 1.2), and then adjust the pH of wastewater to 3.9 ;Then the waste water is sent to the pre-sedimentation tank for natural settlement treatment, press filtration to remove suspended solids and sand in the waste water; a total of about 2.7 tons of sludge is produced, of which 1.4 tons of priceless sludge (nickel dry basis content 2 , the pH to 9.7, and then add 1.2kg of PAM non-ionic flocculant to generate alum flowers; then enter the secondary sedimentation tank, and then remove iron, chromium, nickel, etc. ~1.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com