Frame type direct copper-ceramic bonding plate and manufacturing method thereof

A technology of ceramic copper clad laminate and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of complex installation procedures, easy aging and deterioration of bonding agent, and aging and deterioration of bonding agent, and achieves a simple process. Convenience, avoid aging deterioration, durable bonding and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

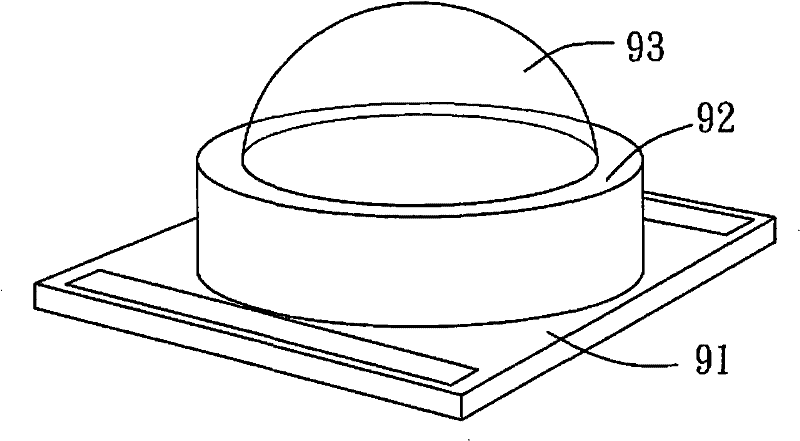

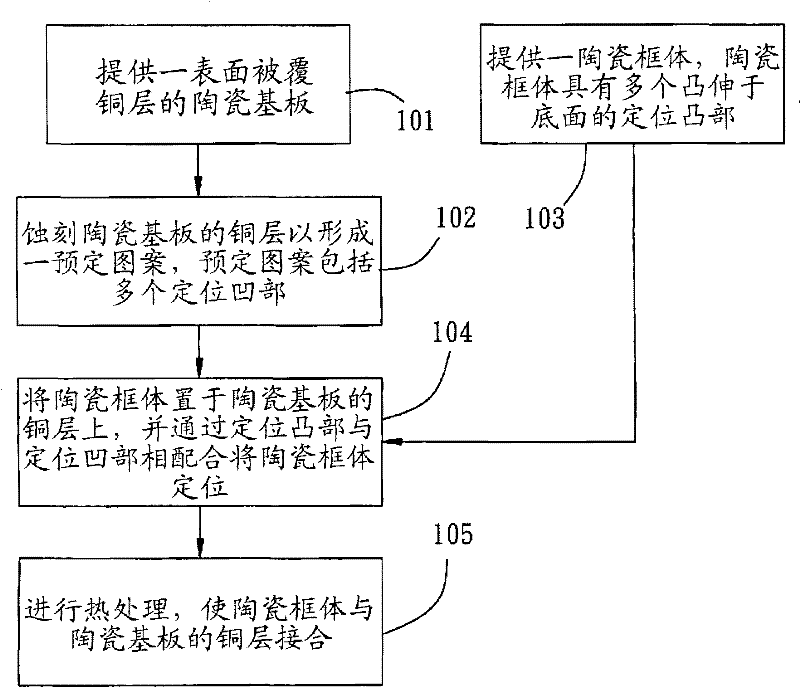

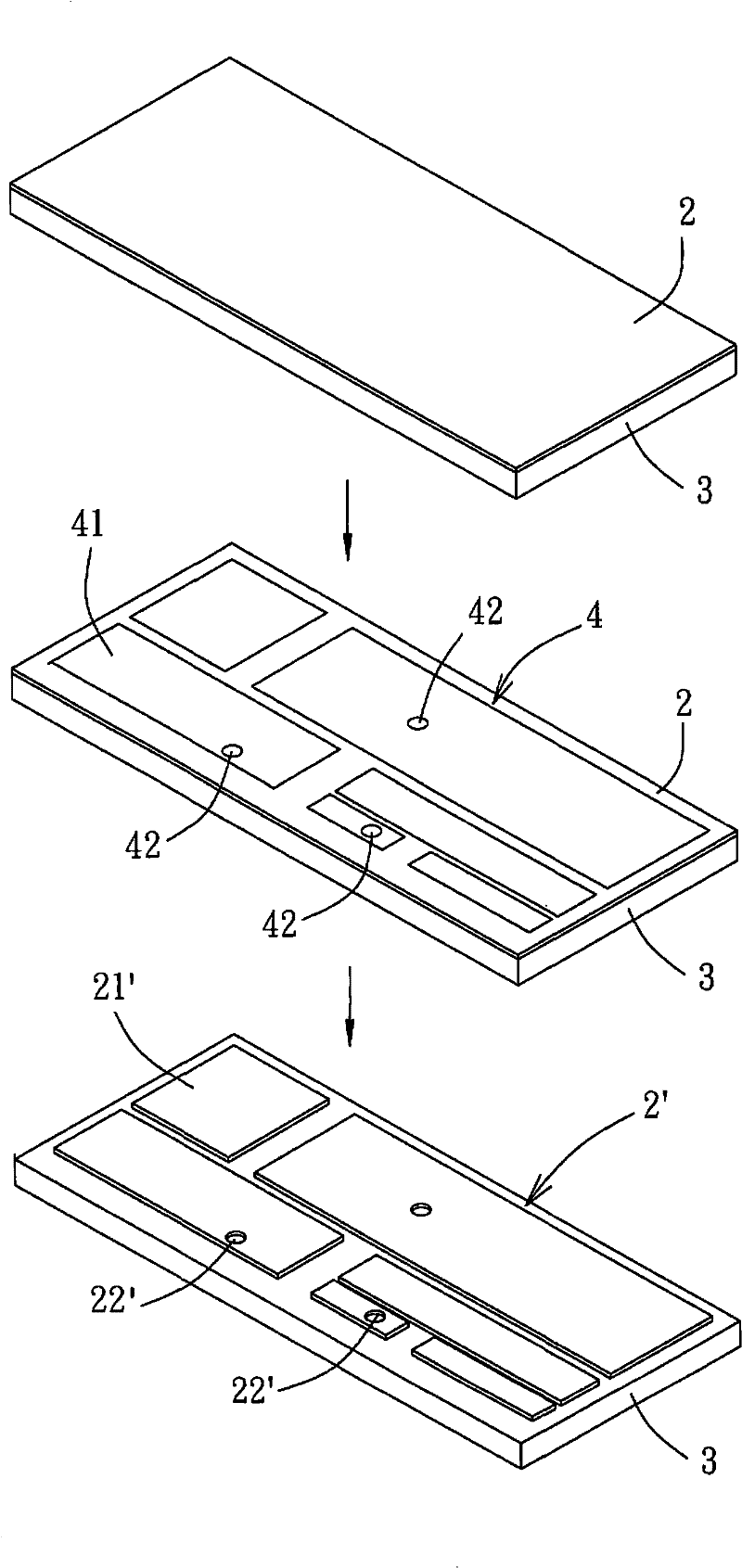

[0030] refer to Figure 2 to Figure 5 , illustrating a method for manufacturing a frame-type ceramic copper-clad laminate and a preferred embodiment of the frame-type ceramic copper-clad laminate of the present invention.

[0031] figure 2 Shown is to make frame-type ceramic copper-clad laminate 100 (such as Figure 5 Shown) is a flow chart of the implementation steps, detailed as follows:

[0032] Cooperate with reference image 3 , as described in step 101, a ceramic substrate 3 whose surface is coated with a copper layer 2 is firstly provided. In this embodiment, the material of the ceramic substrate 3 is alumina, and the copper layer 2 is bonded to the ceramic substrate 3 by direct copper bonding (DBC) , although this embodiment cites a ceramic substrate 3 with a single-sided copper layer 2, a ceramic substrate with a double-sided copper laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com