Production method of sprouting brown rice nutritious biscuit

A technology of germinated brown rice and its production method, which is applied in dough processing, baking, baked food, etc., can solve the problems of insufficient dietary fiber and trace elements, incomplete surface of green body, and influence on the quality of finished biscuits, etc., to improve the brain function, nerve calming, beneficial effects of gastrointestinal peristalsis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

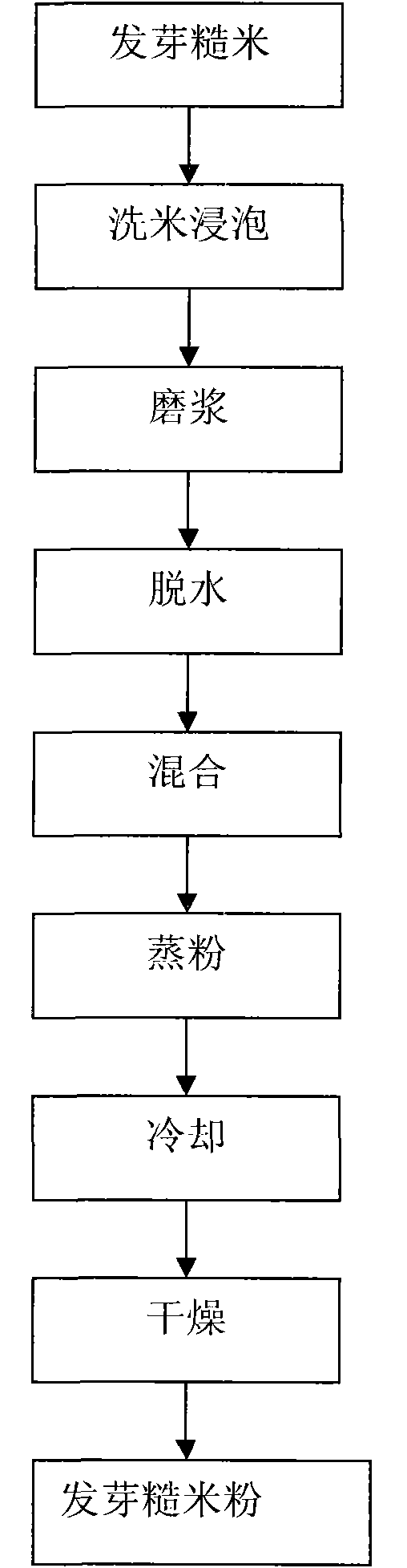

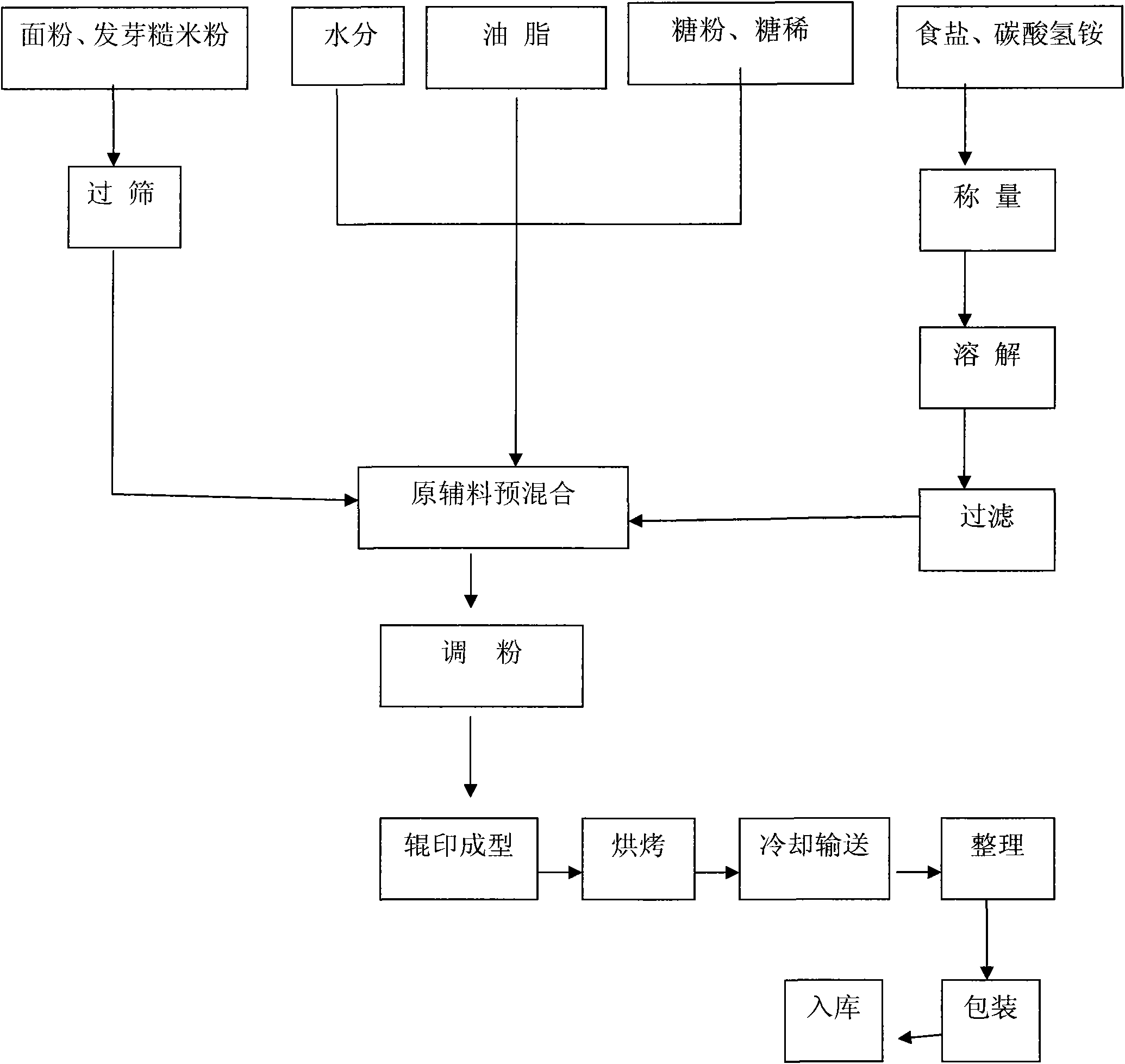

[0021] Soak the germinated brown rice and use a refiner to grind it into a slurry. After dehydration and mixing, put it in a steaming room to steam the flour, cool and dry to obtain germinated brown rice flour, weigh ammonium bicarbonate and mix with warm water at 30°C in parts by weight, and continuously Stir until the ammonium bicarbonate is fully hydrolyzed, take the materials as listed below, all in parts by weight: 50 parts of germinated brown rice flour, 30 parts of powdered sugar, 20 parts of palm flour, 50 parts of flour, 10 parts of starch, 2 parts of starch syrup, carbonic acid 2 parts of ammonium hydrogen, 4 parts of water. Mix germinated brown rice flour, palm oil, starch syrup, hydrolyzed bicarbonate and other raw materials with a dough mixer, then add flour, and make a dough in the dough mixer until the dough is mature and not sticky, let it stand for 15 Minutes later; the prepared dough is laminated, calendered, and shaped to obtain a biscuit embryo; and then th...

Embodiment 2

[0023] Soak the germinated brown rice and use a refiner to grind it into a slurry. After dehydration and mixing, put it into the steaming room to steam the powder, and cool and dry to obtain the germinated brown rice flour. Stir until the ammonium bicarbonate is fully hydrolyzed, take the materials as listed below, all in parts by weight: 100 parts of germinated brown rice flour, 40 parts of powdered sugar, 30 parts of palm powder, 50 parts of flour, 15 parts of starch, 2 parts of starch syrup, carbonic acid 3 parts of ammonium hydrogen, 6 parts of water. Mix germinated brown rice flour, palm oil, starch syrup, hydrolyzed bicarbonate and other raw materials with a dough mixer, then add flour, and make a dough in the dough mixer until the dough is mature and not sticky, let it stand for 15 Minutes later, the prepared dough is laminated, rolled, and shaped to obtain raw biscuit embryos; the raw embryos are baked in an oven to obtain mature biscuits, and the finished product is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com