Method for improving online roll grinding rate of finishing mill

A finishing mill and grinding rate technology, which is applied in the control field of improving the online grinding rate of the work rolls of the hot-rolled strip finishing mill, can solve the problem of reducing the rolling amount of the same width of the strip, affecting the surface quality of the hot-rolled plate, and the surface quality of the work rolls. Roughness and other problems, to achieve the effect of improving surface quality, reasonable program design, and improving surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

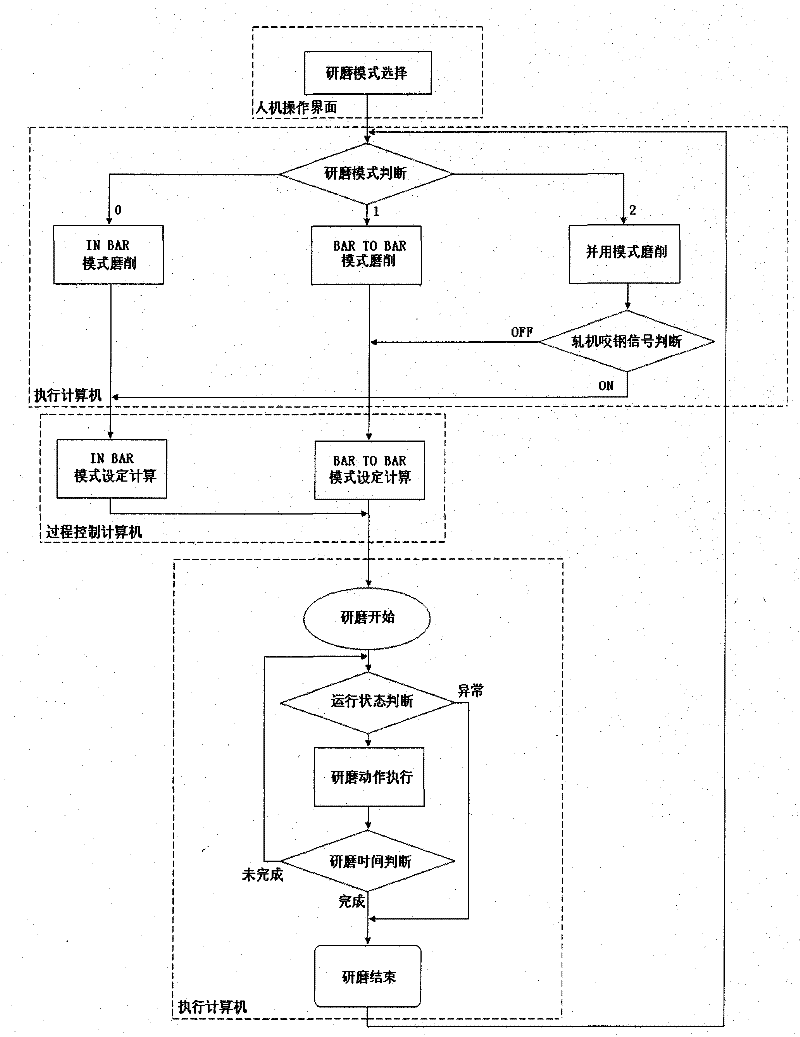

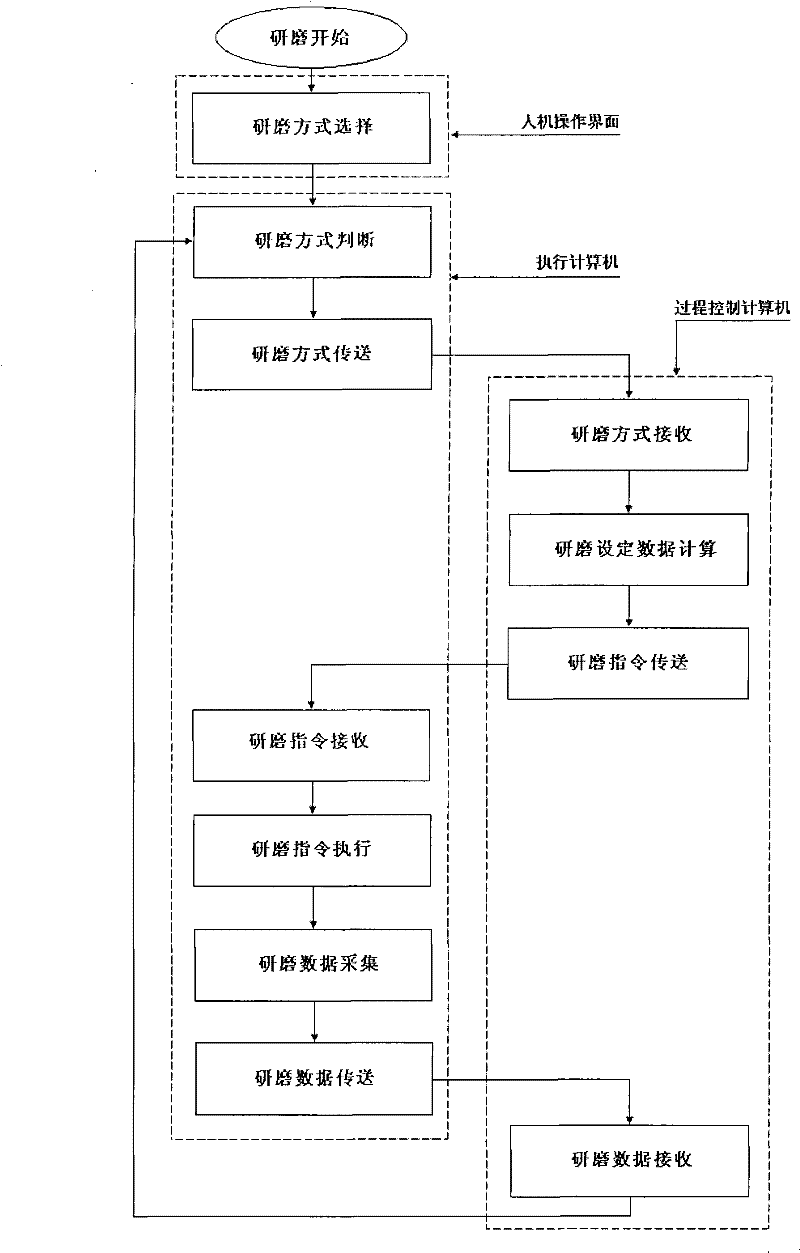

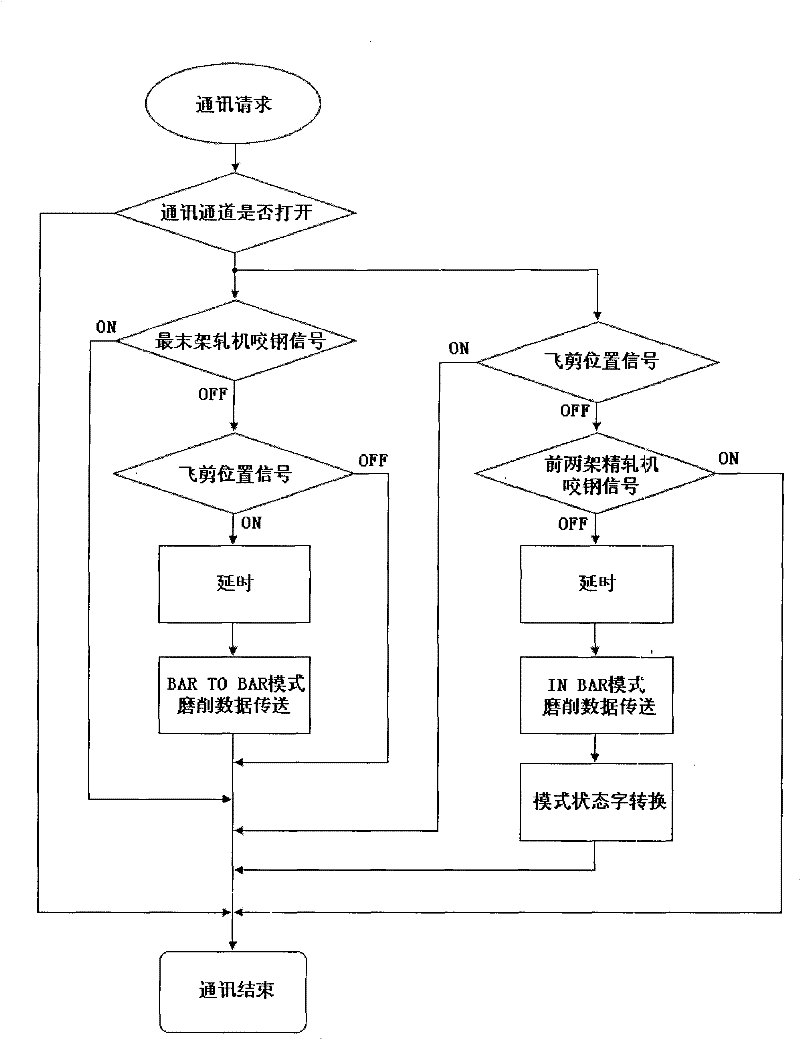

[0022] The method for improving the on-line roll grinding rate of the finishing mill in the present invention is to adopt two grinding heads active on-line roll grinding (ORG) devices, and the application of ORG in the rolling process is mainly based on the process control computer setting method, through the implementation of the computer. On-site rolling data collection, including the collection and feedback of rolling force, rolling material temperature, material, rolling speed, rolling width, rolling volume of the same width, and the grinding data of the last rolling rhythm ORG, through process control The mathematical model of the computer predicts and calculates the wear of the roll, and sets the grinding time based on the calculated data, and controls the execution computer to select the grinding method according to the needs within a rolling rhythm, and can implement IN BAR or BAR alone TO BAR two grinding methods, respectively, after the steel is bitten or thrown in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com