Inorganic hydrated salt silica phase-change material and preparation method thereof

A technology of inorganic hydrated salt and silica, applied in chemical instruments and methods, materials for heat exchange, etc., can solve problems such as supercooling and phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

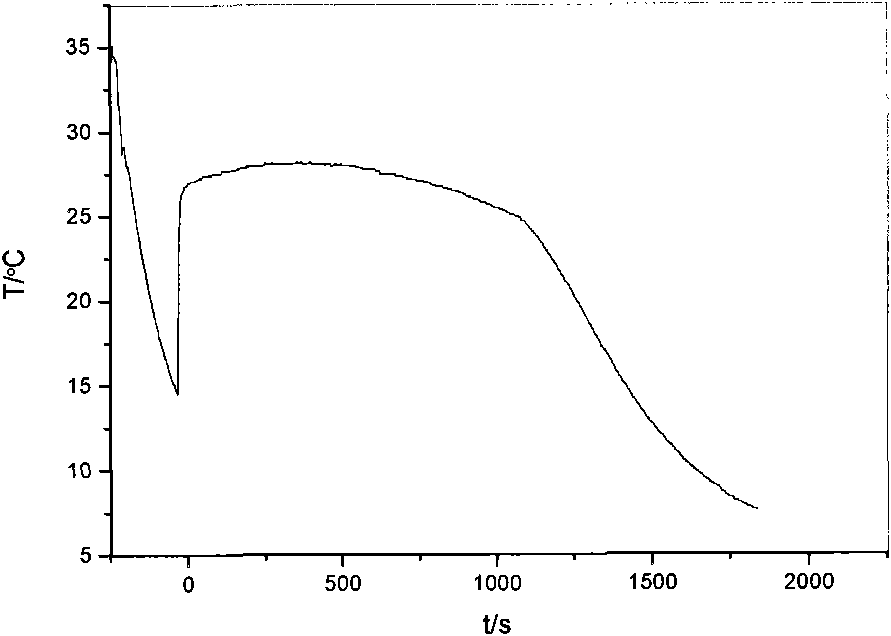

Embodiment 1

[0026] Proceed according to the scheme given in Table 1:

[0027] A, add 18 grams of anhydrous sodium sulfate particles in 40 grams of water, stir evenly under 45 ℃ of conditions, make sodium sulfate inorganic hydrated salt saturated solution, then the inorganic hydrated salt saturated solution that makes is equally divided into two parts.

[0028] B. Slowly add 2ml of 98wt% concentrated sulfuric acid solution dropwise to one of the inorganic hydrated salt solutions, and magnetically stir evenly at 45°C to obtain an inorganic hydrated salt sulfuric acid solution.

[0029] C. Add 10 grams of sodium metasilicate nonahydrate particles to another inorganic hydrated salt solution, and stir at 45°C until the sodium metasilicate nonahydrate is completely dissolved to obtain an inorganic hydrated sodium metasilicate solution.

[0030] D, under the condition of magnetic stirring at 45°C, slowly add 5ml of cyclohexane and 0.1ml of sorbitan monooleate (span80) dropwise to the inorganic h...

Embodiment 2

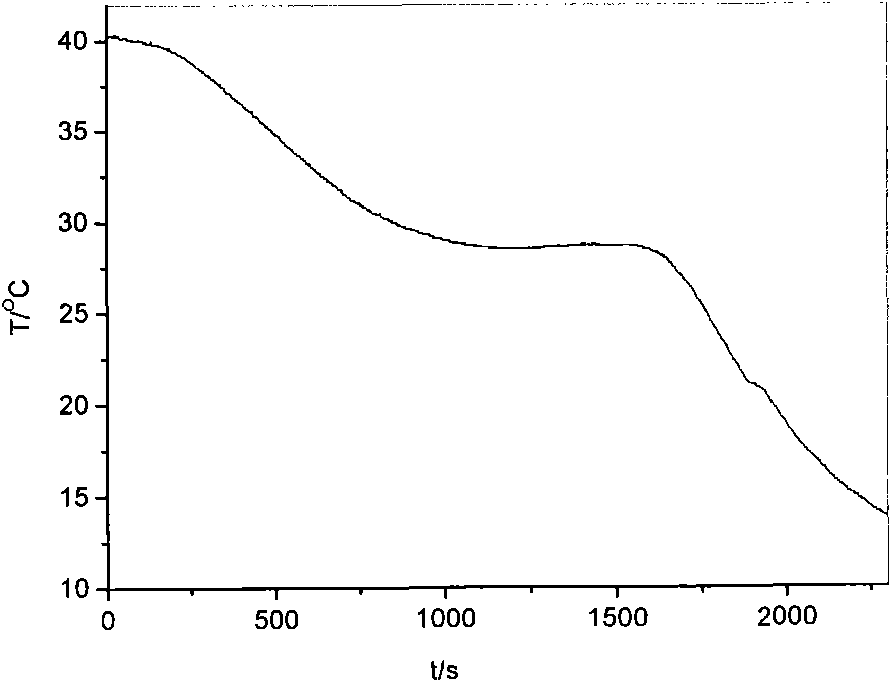

[0036] Repeat the experimental steps in Example 1 according to the scheme given in Table 1, but after mechanical stirring to obtain a uniform suspension of colloidal particles, it is transferred to a suitable container and placed in the air at a temperature of 10 to 20 ° C. After standing for 1-3 hours, and sealing the upper surface with dimethyl silicone oil, an inorganic hydrated silicon dioxide phase-change material with a stable porous microstructure can be prepared.

[0037] The step cooling curve figure of this embodiment is as Figure 2b shown.

Embodiment 3

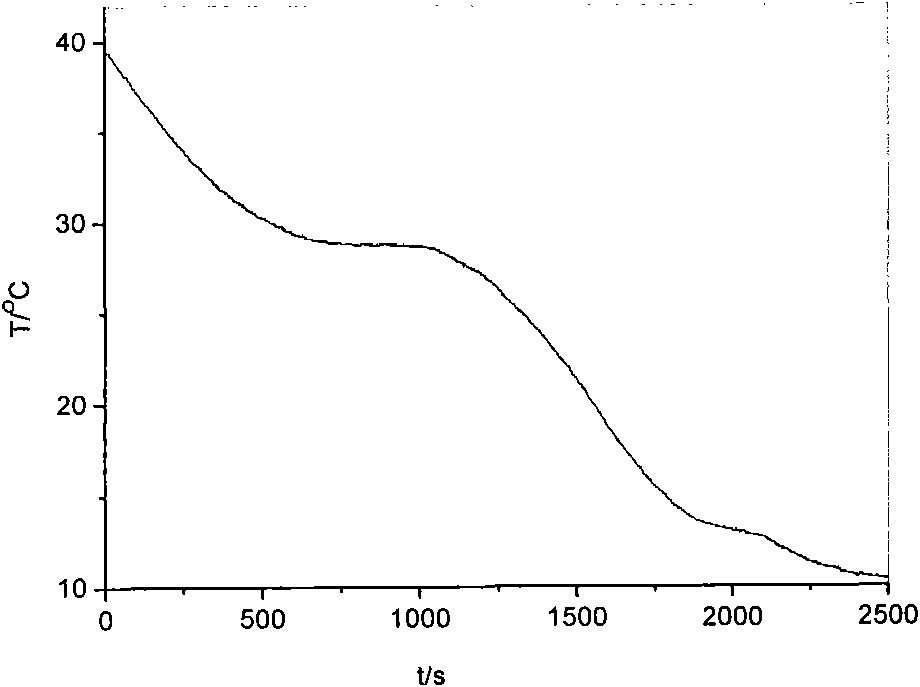

[0039] Repeat the experimental steps in Example 2 according to the scheme given in Table 1, but the volume of the 98% concentrated sulfuric acid added dropwise in step B is 3mL, the quality of the sodium metasilicate nonahydrate added in step C is 15g, and the colloidal particles The time for the suspension to stand in the air is 1 to 2 hours.

[0040] The step cooling curve figure of this embodiment is as Figure 2c shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com