LED light source using fluorescence conversion device with transparent base material

A technology of LED light source and conversion device, which is applied to the parts of lighting devices, optical elements used to change the spectral characteristics of emitted light, lighting devices, etc. Precise control is difficult and other problems to achieve the effect of simple preparation method, improved consistency, and avoidance of thermal aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

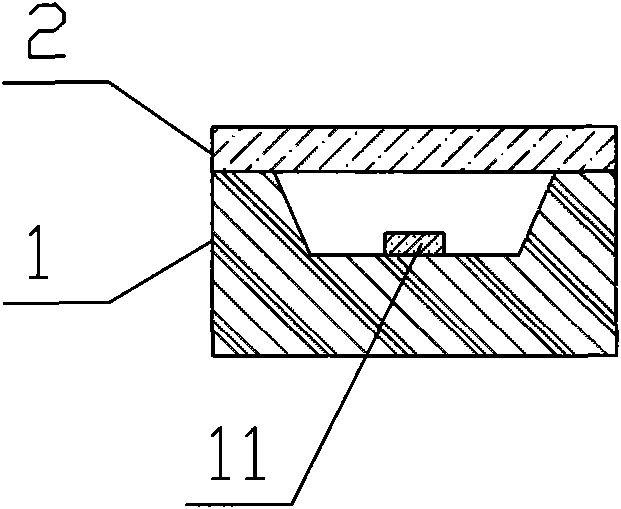

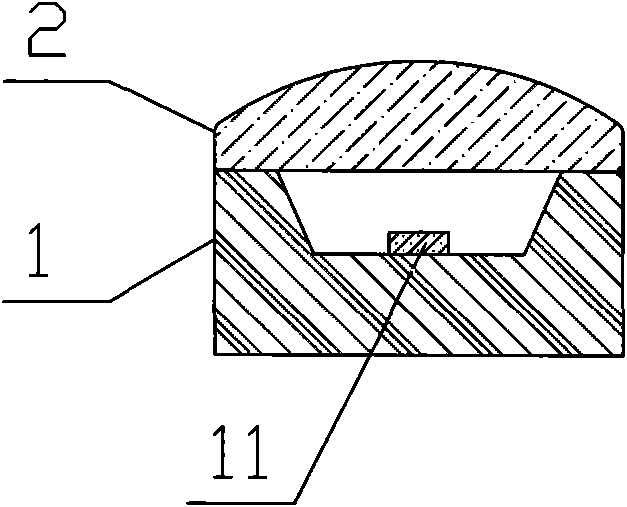

[0059] see figure 1 , an LED device 1, in which an LED chip 11 is packaged, and a fluorescent conversion device 2 is located above the LED chip 11 and fixed.

[0060] When working, the light emitted by the LED chip 11 must pass through the fluorescent conversion device 2 before it can be emitted to the outside. The blue light excites the phosphor film layer on the fluorescent conversion device, and the light emitted by the chip under electric drive excites the phosphor to produce visible light in other bands. , each part mixes colors to form white light.

[0061] The main wavelength emitted by the LED chip 11 generally ranges from 420nm to 480nm, and the composition of the phosphor film layer on the phosphor conversion device is aluminate YAG phosphor that can excite yellow light. The blue light emitted by the LED chip passes through the fluorescent conversion device and excites the phosphor film layer on the fluorescent conversion device, and part of the blue light is conver...

Embodiment 2

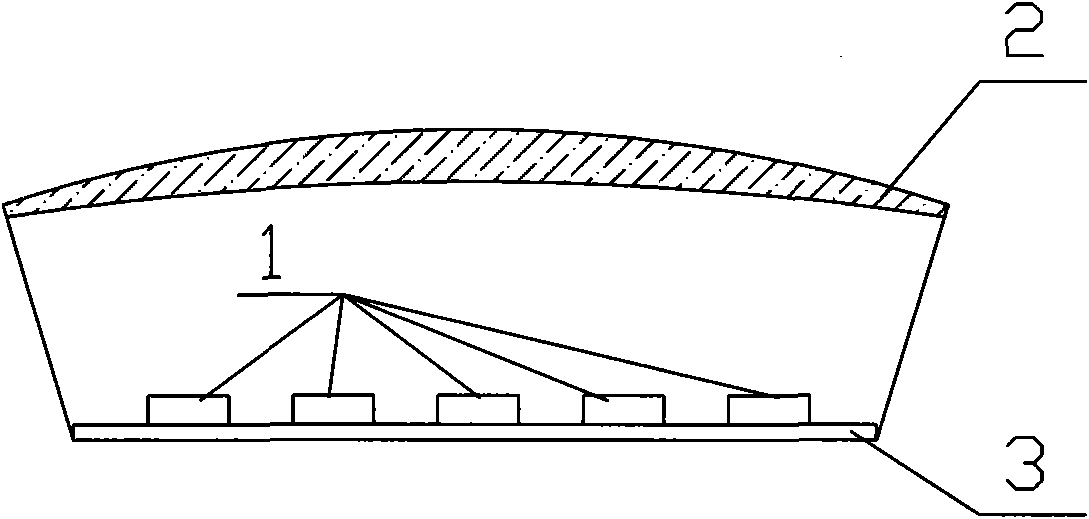

[0072] It is basically the same as Embodiment 1, except that the transparent base material of the fluorescent conversion device is formed into a circular lens curved surface, such as image 3 shown; or shaped into a square lens surface, and then cleaned and coated.

Embodiment 3

[0074] It is basically the same as the first embodiment, the difference is that multiple LED chips with the same wavelength are packaged in one LED device, for example, two blue light chips are packaged together, and the main emission wavelength range is generally 420nm-480nm.

[0075] The blue light emitted by the LED chip passes through the fluorescent conversion device and excites the phosphor film layer on the fluorescent conversion device, and part of the blue light is converted into yellow light; the mixture of blue light and yellow light produces white light, and the color coordinates and color temperature depend on the ratio of blue light and yellow light . The spectral composition of LED light sources such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com