Laser power detection device and detection method thereof

A technology for optical power detectors and detection devices, applied in measuring devices, photometry, optical radiation measurement, etc., can solve the problem of not being able to measure the number of laser pulses at the same time, continuous working time not being too long, and damage to the carbon bucket detection surface and other problems, to achieve the effect of convenient and fast measurement, stable work and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

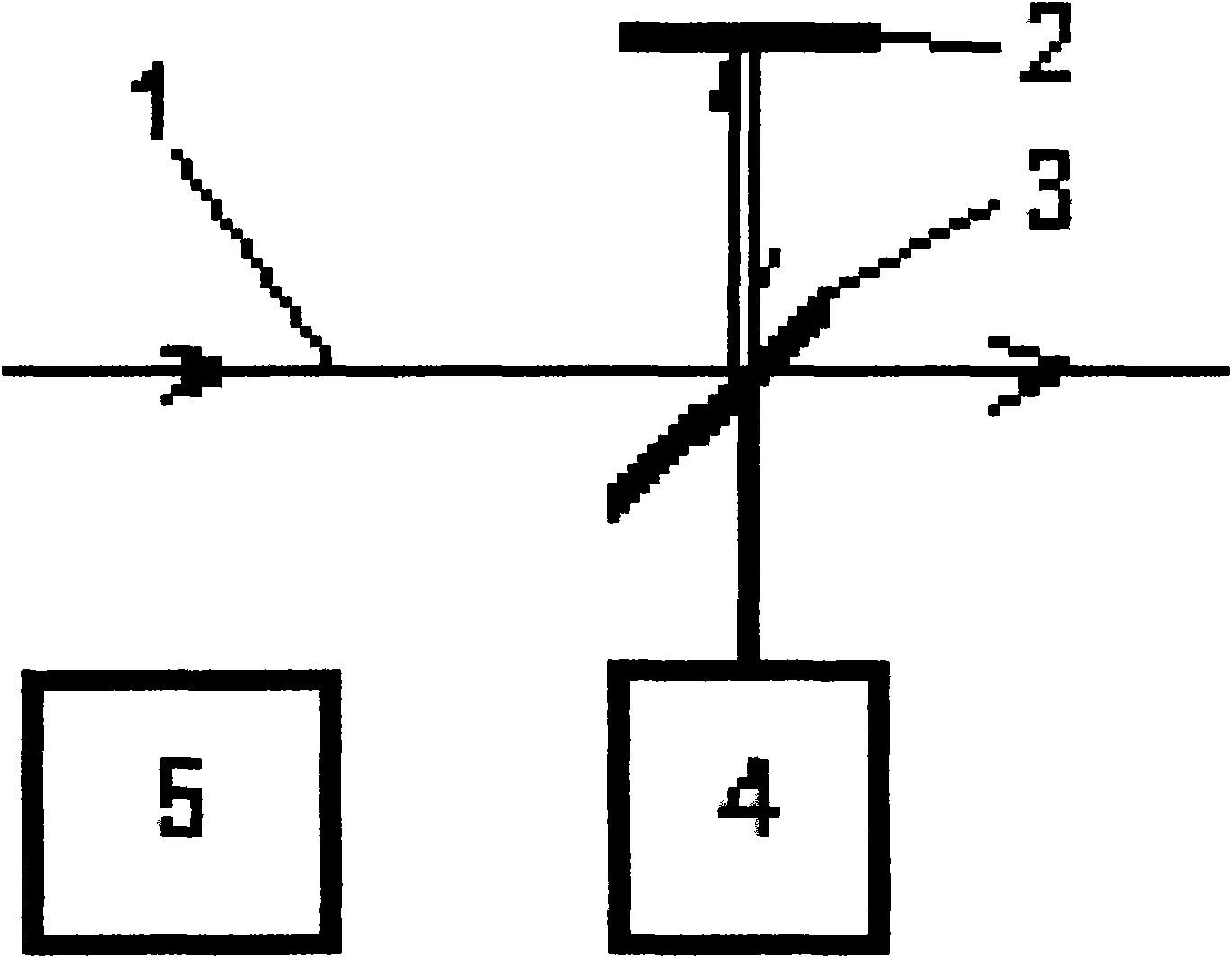

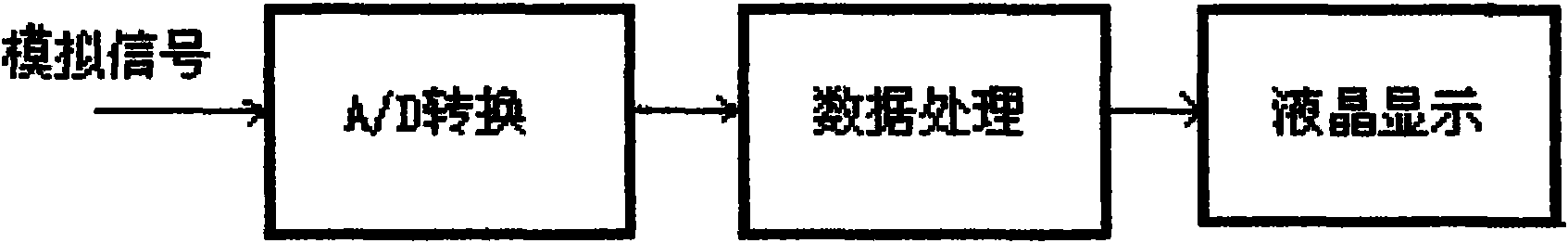

[0018] see figure 1 An attenuator composed of two white sapphire glass lenses is interposed between the laser light 1 to be measured and the light detection component 4 . The first white sapphire glass lens 3 in the attenuator is located on the optical path of the laser light 1 to be measured, and is set at an angle of 45 degrees to the optical path of the laser light 1 to be measured, and the second white sapphire glass lens 2 is located on the optical path of the first white sapphire glass lens 3 The reflected optical path, and its mirror surface is parallel to the optical path of the laser to be measured 1; wherein, the thickness of the first white sapphire glass lens 3 and the second white sapphire glass lens 2 are both 3mm. The photodetector 4 is located on the reflected light path of the second white sapphire glass lens 2 on the back of the first white sapphire glass lens 3 . Optical detection part 4 is made up of optical power detector and optical pulse detector, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com