Non-linear taper inverted cone coupler structure

A coupler and non-linear technology, applied in the field of integrated optics, can solve the problems of unfavorable size and high manufacturing process requirements, and achieve the effect of reducing the difficulty of process manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

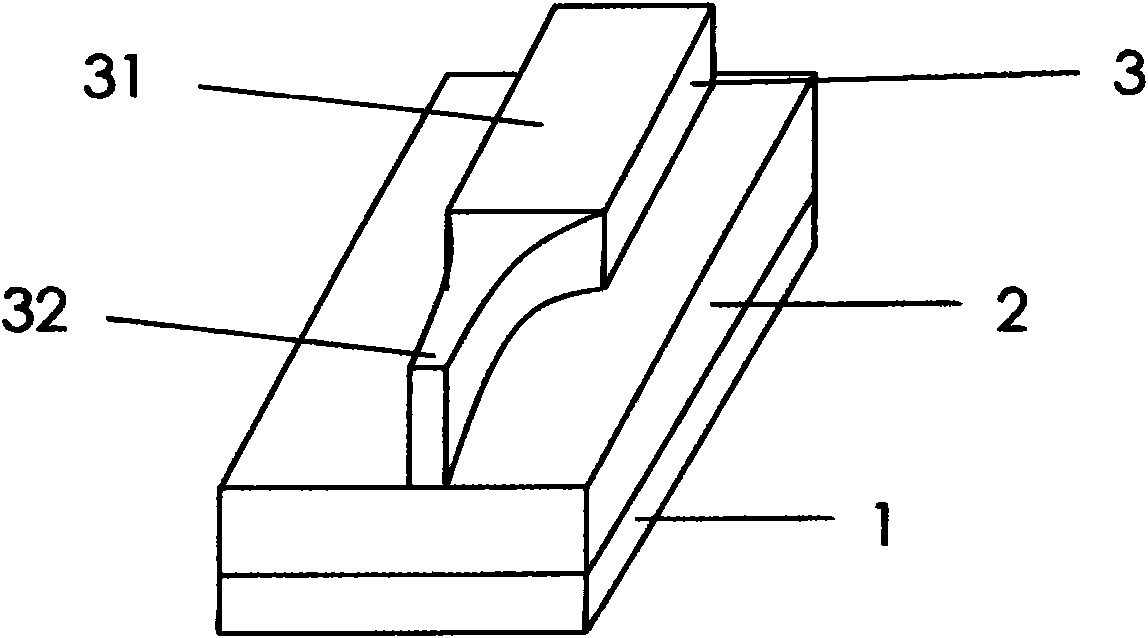

[0028] see figure 1 As shown, the present invention provides a non-linear tapered inverted cone coupler structure, comprising:

[0029] A substrate 1. The material of the substrate 1 is silicon, and its function can not only provide the substrate, but also play the role of an effective heat conducting layer.

[0030] A buried oxide layer 2, the buried oxide layer 2 is made on the substrate 1, the material of the buried oxide layer 2 is silicon dioxide; the buried oxide layer 2 can be used as an electromagnetic and radiation blocking layer, and can also be used as an etching As of now. The buried oxide layer 2 is obtained by thermal oxidation.

[0031] A top layer of silicon 3, the top layer of silicon 3 is fabricated on the buried oxide layer 2, which can effectively prevent light from leaking into the substrate 1, and the top layer of silicon 3 is bonded by Smart Cut technology. One end of the top layer of silicon 3 is a strip waveguide 31, which is used to transmit the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com