Fast recovery diode and manufacturing method thereof

A recovery diode and manufacturing method technology, applied in the field of microelectronics, to achieve the effect of ensuring uniformity and solving the problem of uniformity of switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention provide a fast recovery diode and a manufacturing method thereof, which can solve the problem of DIE-to-DIE and WAFER-to-WAFER switching speed uniformity.

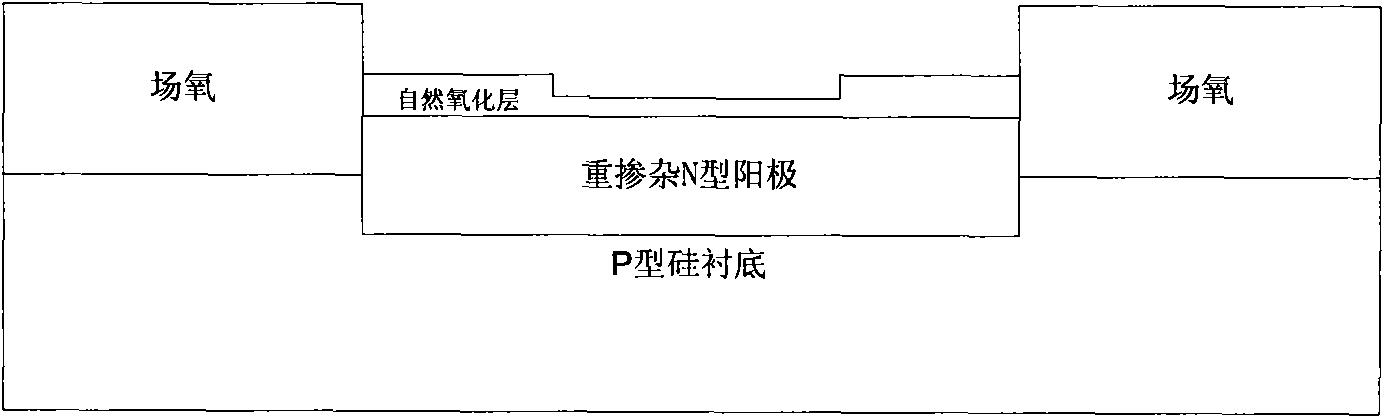

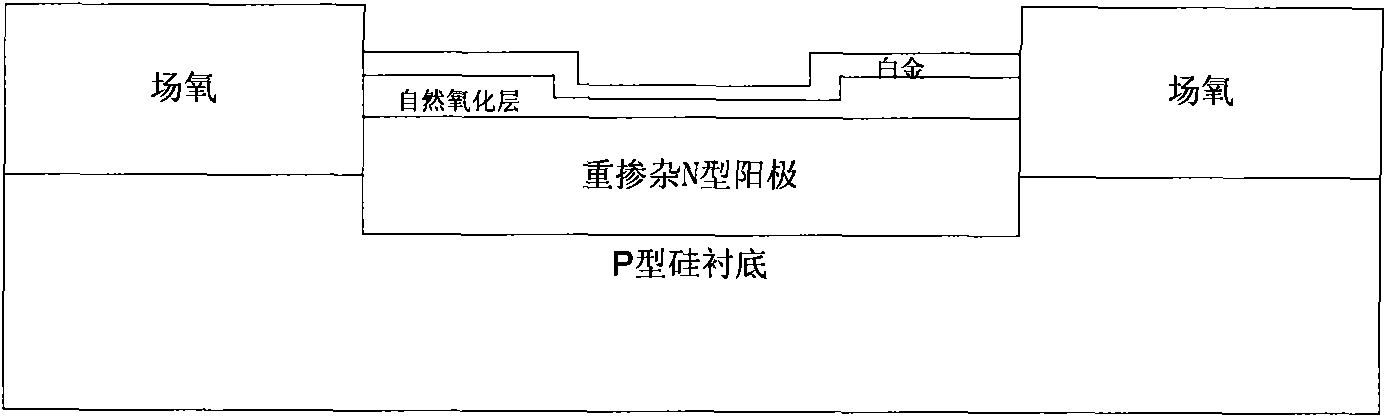

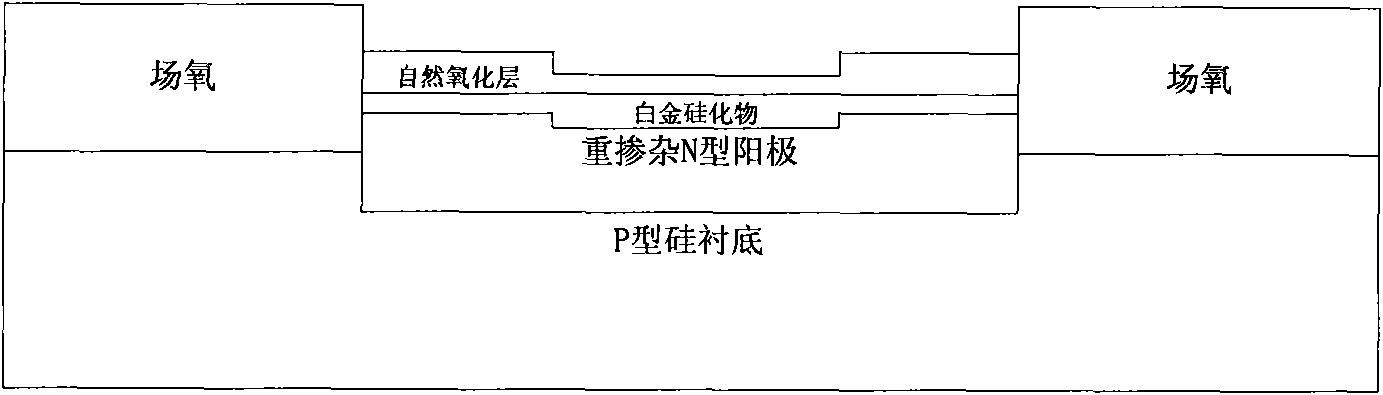

[0020] The fast recovery diode of the embodiment of the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

[0021] figure 2 It is a structural schematic diagram of an FRD embodiment of the present invention, such as figure 2 As shown, the fast recovery diode of the embodiment of the present invention includes: a silicon substrate, a heavily doped anode deposited on the silicon substrate, and field oxygen deposited on the silicon substrate and on both sides of the heavily doped anode, It also includes: a platinum silicide layer formed on the heavily doped anode and a uniform silicon dioxide layer formed on the platinum silicide layer.

[0022] In the fast recovery diode provided by the embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com