Fire-proof oven doors and fire-proof oven door frame walls of a coke oven battery

A technology for coke oven clusters and coke ovens, which is applied to doors/closures of coke ovens, heating of coke ovens, coke ovens, etc., can solve problems such as difficult operation of coke oven chambers, coke oven operation problems, and environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

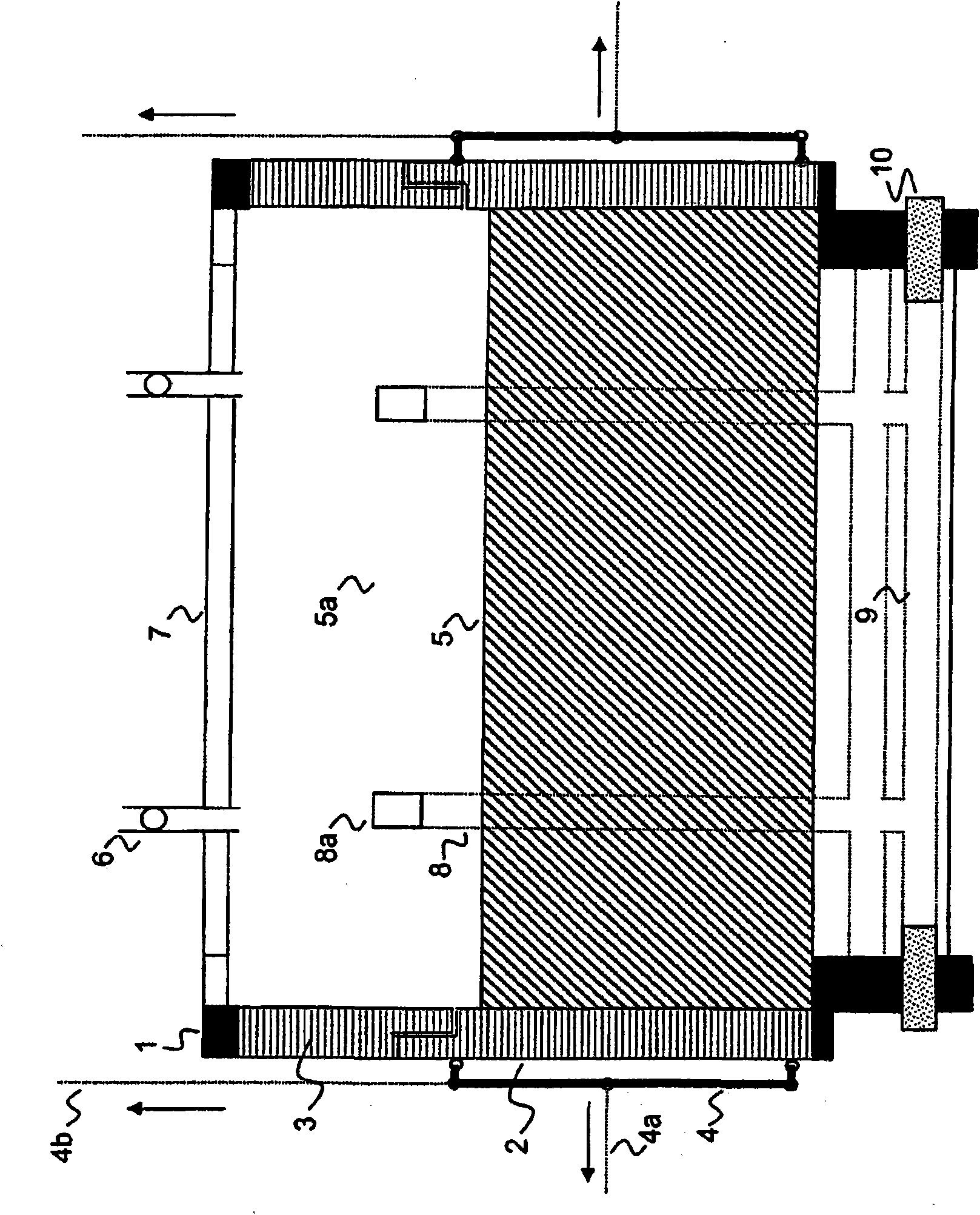

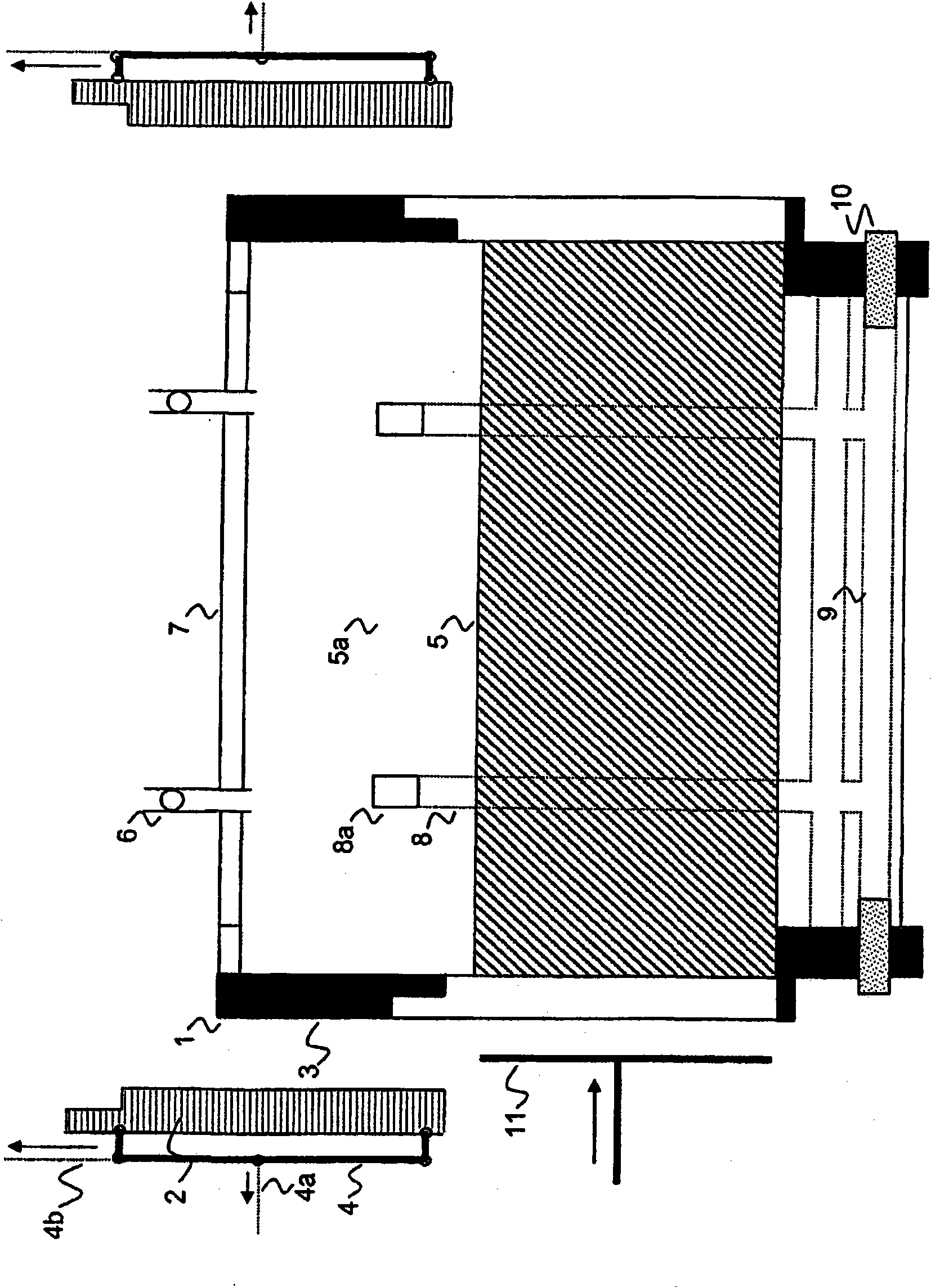

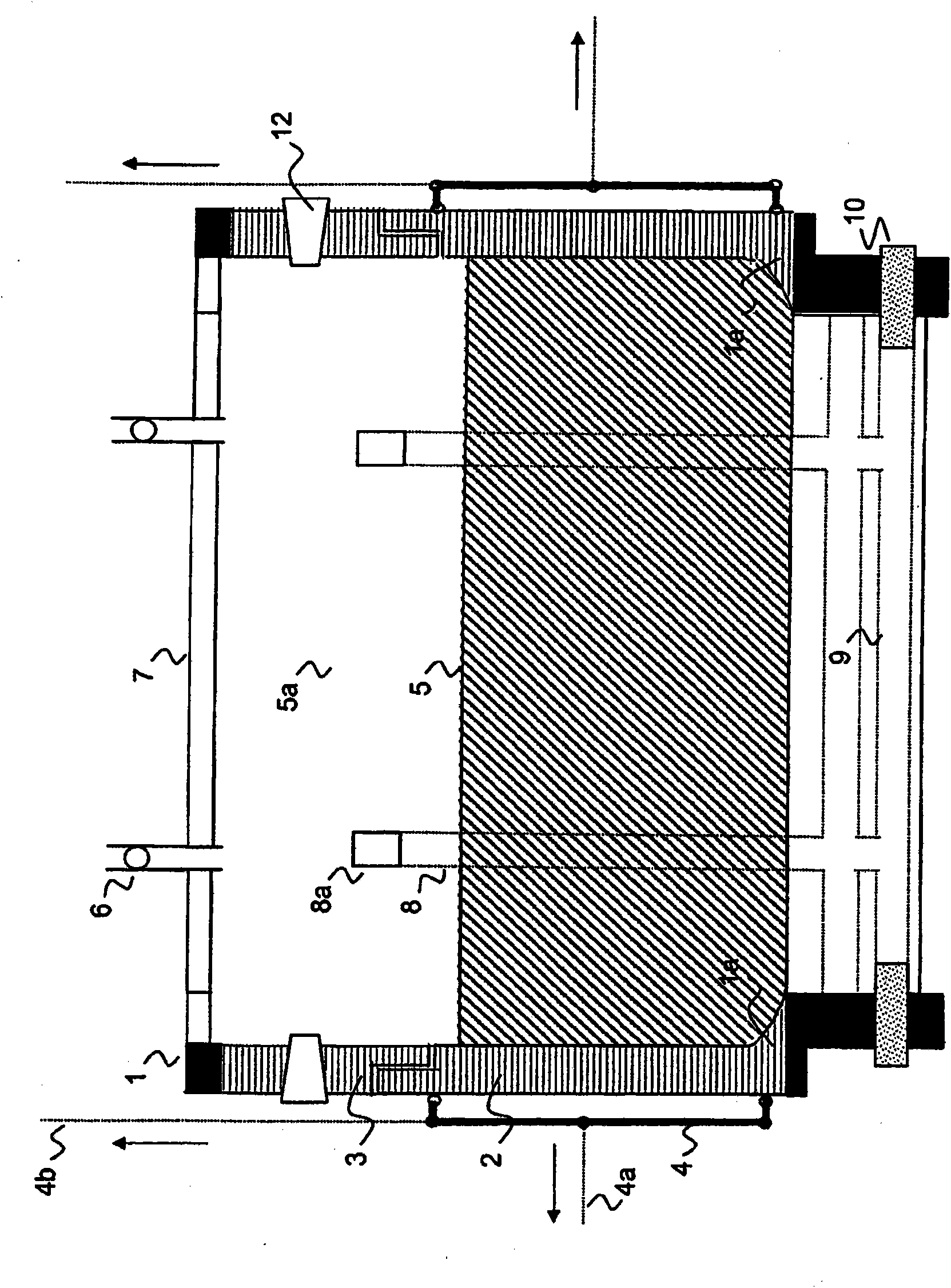

[0056] figure 1 : The coke oven chamber (1) is loaded with coal and closed with a door (2) made of refractory material. Preferably, materials containing silica or containing silica and alumina are suitable as the refractory material. The horizontally oriented wall ( 3 ) surrounding the furnace door is likewise made of this material, so that the door cannot be distorted due to the same coefficient of thermal expansion. The door is suspended from a support frame (4) on which a coupling (4a) to the drive mechanism is fixed for pulling out the door. On this support frame there is likewise a connecting piece ( 4 b ) for the lift gate. Access to the coke oven (1) can thus be obtained. In the coke oven there are coke cakes ( 5 ), which are not filled all the way to the top of the coke oven, but only up to a defined filling level. Above the coke cake there is a gas collection chamber (5a). Ventilation openings (6) are located on the coke oven roof (7), through which the primary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com