Process for preparing bupleurum chinense injection

A technology of injection and Bupleurum, applied in the field of preparation of Bupleurum injection, can solve problems such as low volatile oil content of Bupleurum, poor product stability, toxic and side effects, etc., and achieve the effects of avoiding toxic and side effects, improving stability, and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

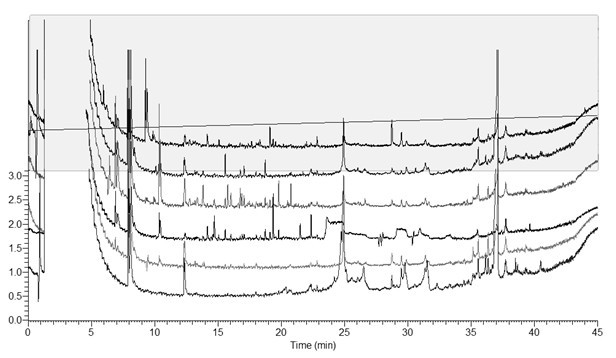

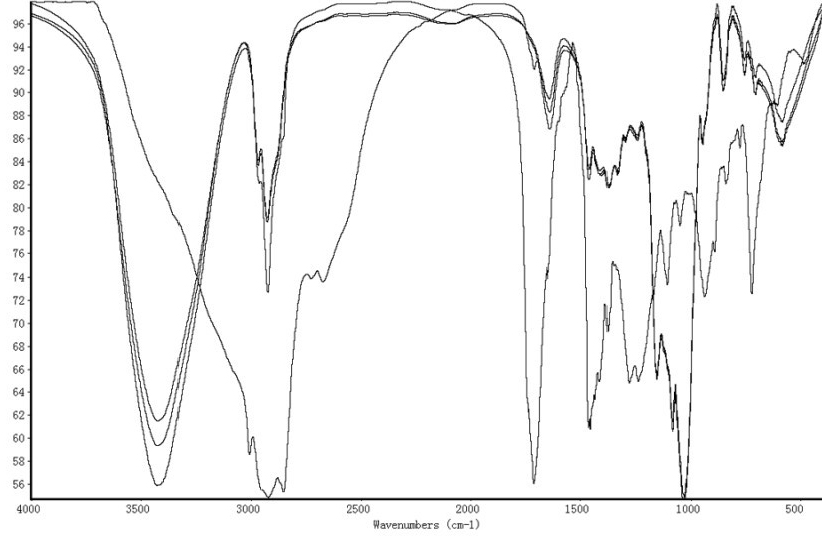

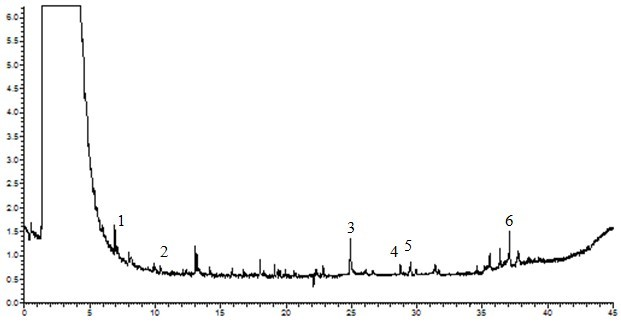

Image

Examples

Embodiment 1

[0047] Bupleurum injection in the present embodiment is prepared by the following method:

[0048] (1) Take 1000g of Bupleurum medicinal material, crush it to 20-60 mesh, and extract the volatile oil of Bupleurum with carbon dioxide supercritical extraction equipment:

[0049] Put the pulverized Bupleuri herb into the extraction kettle, and then pump the supercritical medical grade carbon dioxide fluid through the purifier, cooling system and high-pressure pump into the extraction kettle at a flow rate of about 20kg / h. Extraction under the condition of 20MPa pressure for 1.5h;

[0050] The extract is separated in two stages. The operating conditions of the separation kettle I are: pressure 12MPa, temperature 40°C, and the operating conditions of the separation kettle II are: pressure 6MPa, temperature 25°C; collected from the outlet of the two-stage separation kettle Bupleurum supercritical product;

[0051] (2) Distill the Bupleurum supercritical product extracted in step (...

Embodiment 2

[0055] The preparation method of the Bupleurum injection of the present embodiment is as follows:

[0056] (1) Take 1000g of Bupleurum medicinal material, crush it to 20-60 mesh, and extract the volatile oil of Bupleurum with carbon dioxide supercritical extraction equipment: the extraction process is the same as in Example 1, wherein the flow rate of the supercritical medical grade carbon dioxide fluid is 25kg / h, The extraction conditions are: 45°C, 25MPa, and the extraction time is 1h. The operating conditions of the separation tank I are: the pressure is 12MPa, the temperature is 35°C, the operating conditions of the separation tank II are: the pressure is 6MPa, the temperature is 30°C; The supercritical product with Bupleurum volatile oil as the main component is collected at the outlet of the fractional separation kettle;

[0057] (2) Distill the Bupleurum supercritical product extracted in step (1) with 80 times the amount of water for 3 hours to obtain about 2000 mL of ...

Embodiment 3

[0061] The preparation method of the Bupleurum injection of the present embodiment is as follows:

[0062] (1) Take 1000g of Bupleurum medicinal material, crush it to 20-60 mesh, and extract the volatile oil of Bupleurum with carbon dioxide supercritical extraction equipment: the extraction process is the same as in Example 1, wherein the flow rate of the supercritical medical grade carbon dioxide fluid is 25kg / h, The extraction conditions are: 35°C, 20MPa, the extraction time is 2h, the operating conditions of the separation tank I are: pressure 8MPa, temperature 35°C, the operating conditions of the separation tank II are: pressure 7MPa, temperature 30°C; The supercritical product of Bupleurum bupleuri is collected from the outlet of the fractional separation kettle ;

[0063] (2) Distill the Bupleurum supercritical product extracted in step (1) with 60 times the amount of water for 2 hours to obtain about 1500 mL of distillate.

[0064] (3) Add HP-β-CD to the supercritica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com