Isocyanuric ring-containing terminal hydrogenpolysiloxane

A technology of hydrogen polysiloxane and isocyanuric acid, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of inconvenience, general products and methods without suitable structures and methods, and easy to adhere to dust, etc. Achieve excellent optical properties

Active Publication Date: 2010-11-17

SHIN ETSU CHEM IND CO LTD

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, such a curable silicone rubber composition has a siloxane bond unique to silicone, so due to its ion binding property, there is a phenomenon that it is used under extremely severe conditions such as high temperature humidification. In the environment of use, the excellent characteristics of silicone such as chemical resistance, water resistance, and gas permeability cannot be exerted

Moreover, there are also the following disadvantages: the surface of the cured product is sticky, and it is easy to adhere to dust, etc.

This shows that the above-mentioned existing curable silicone rubber composition obviously still has inconvenience and defects in product structure and use, and needs to be further improved urgently

In order to solve the above-mentioned problems, the relevant manufacturers have tried their best to find a solution, but no suitable design has been developed for a long time, and there is no suitable structure and method for general products and methods to solve the above-mentioned problems. This is obviously a problem that relevant industry players are eager to solve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

example 1

example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

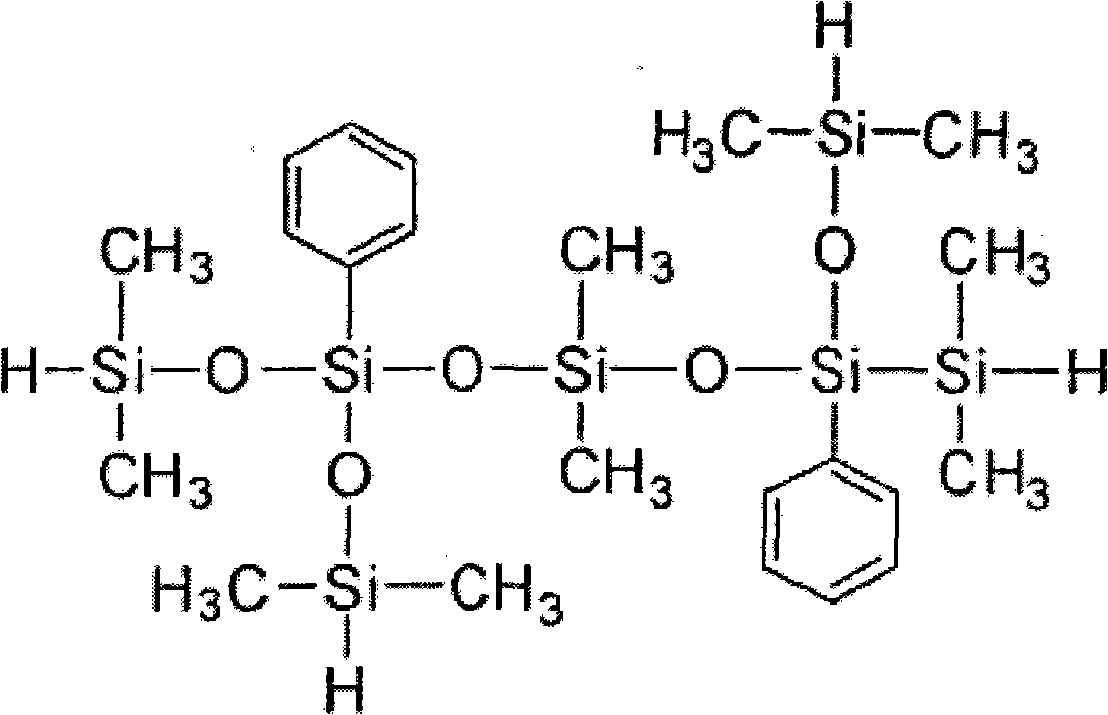

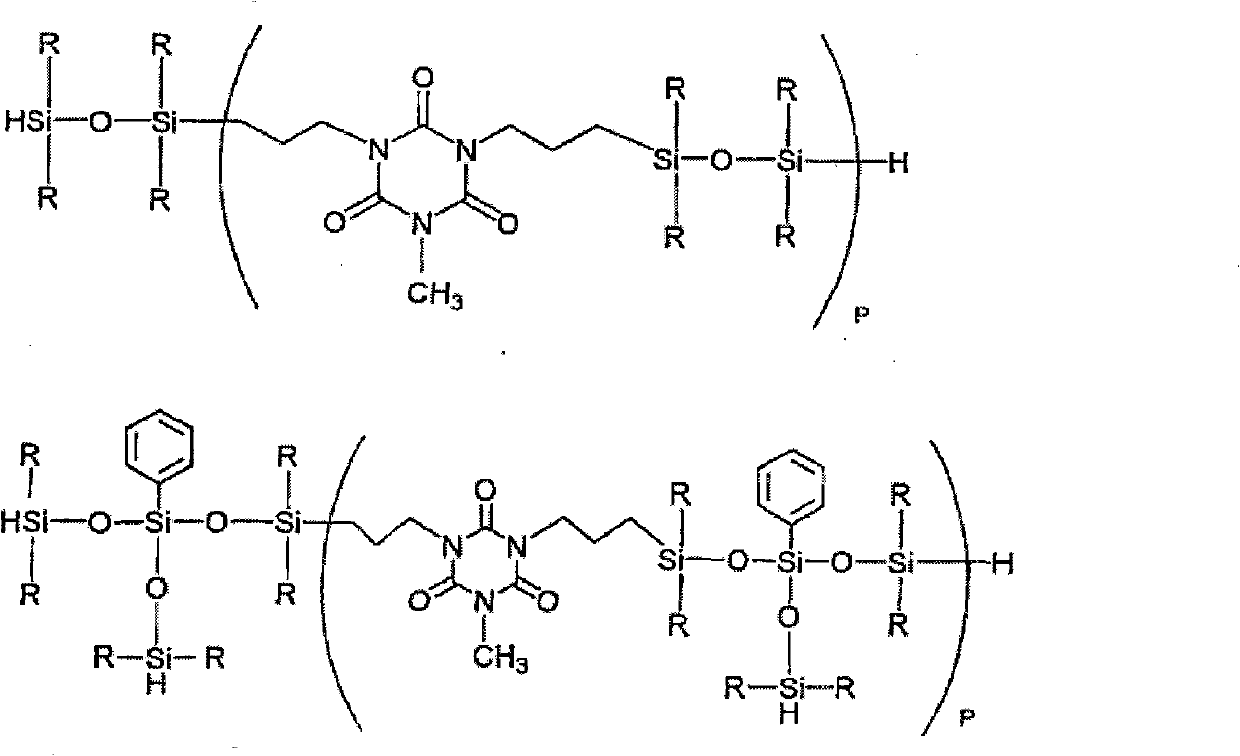

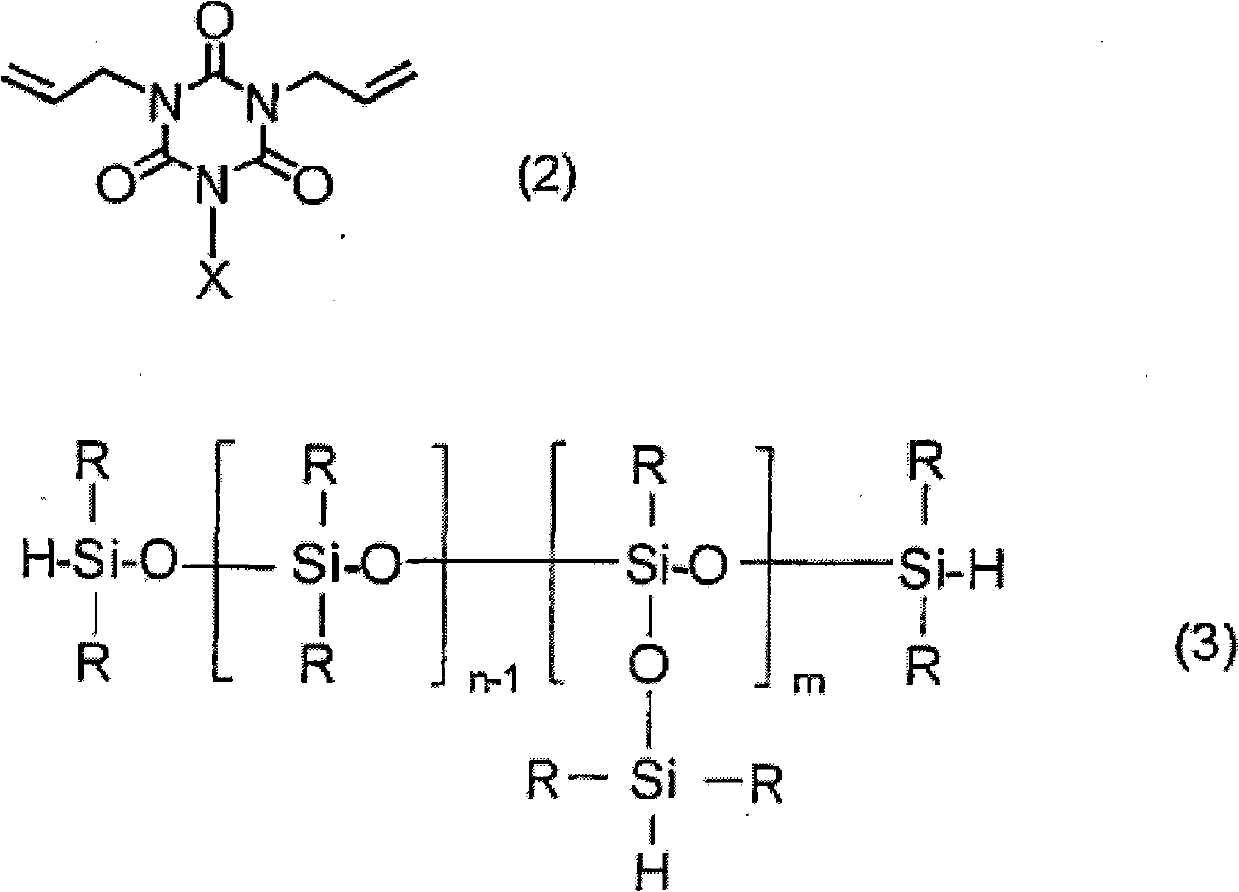

The invention relates to a hydrogenpolysiloxane, shown as the formula (1), having isocyanuric ring, and has at least two terminal hydrogensiloxy: (X are mutually independent univalence organic group not containing unsaturated bonds, R are mutually independent methyl or phenyl, n is an integer from 1 to 50, m is an integer from 0 to 5, and P is an integer from 1 to 10). As the present invention is an isocyanuric ring-containing terminal hydrogenpolysiloxane having at least two hydrogensiloxys at ends, thus it is suitable for use in optical semiconductor sealants and the like agent.

Description

technical field The present invention relates to an organopolysiloxane having a hydrogen polysiloxane moiety at the terminal, capable of producing electrical properties such as heat resistance, mechanical strength, electrical insulation, gas permeability such as water vapor permeability resistance, and transparency. A hardened product with excellent optical properties such as optical properties, chemical resistance, and water resistance. Background technique Hitherto, hardening silicone rubber (siliconerubber) compositions using an addition curing reaction have been widely used. This curable silicone rubber composition is excellent in weather resistance, heat resistance, and electrical insulation, and is widely used as gasket materials, potting materials, and coatings for electrical and electronic parts. Molding materials such as coating materials, roll materials, and impression materials, materials for wire coating, and automotive parts materials. In addition, the optical...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G77/54H01L23/29

Inventor 田中隼人盐原利夫柏木努

Owner SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com