Functional urea-based lubricating grease and preparation method thereof

A technology of urea-based grease and lubricating grease, which is used in lubricating compositions, petroleum industry, thickeners, etc., can solve the problems of poor oxidation resistance, high content of antioxidant additives, increase production cost, etc., and achieve high colloidal stability. , good anti-oxidation, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

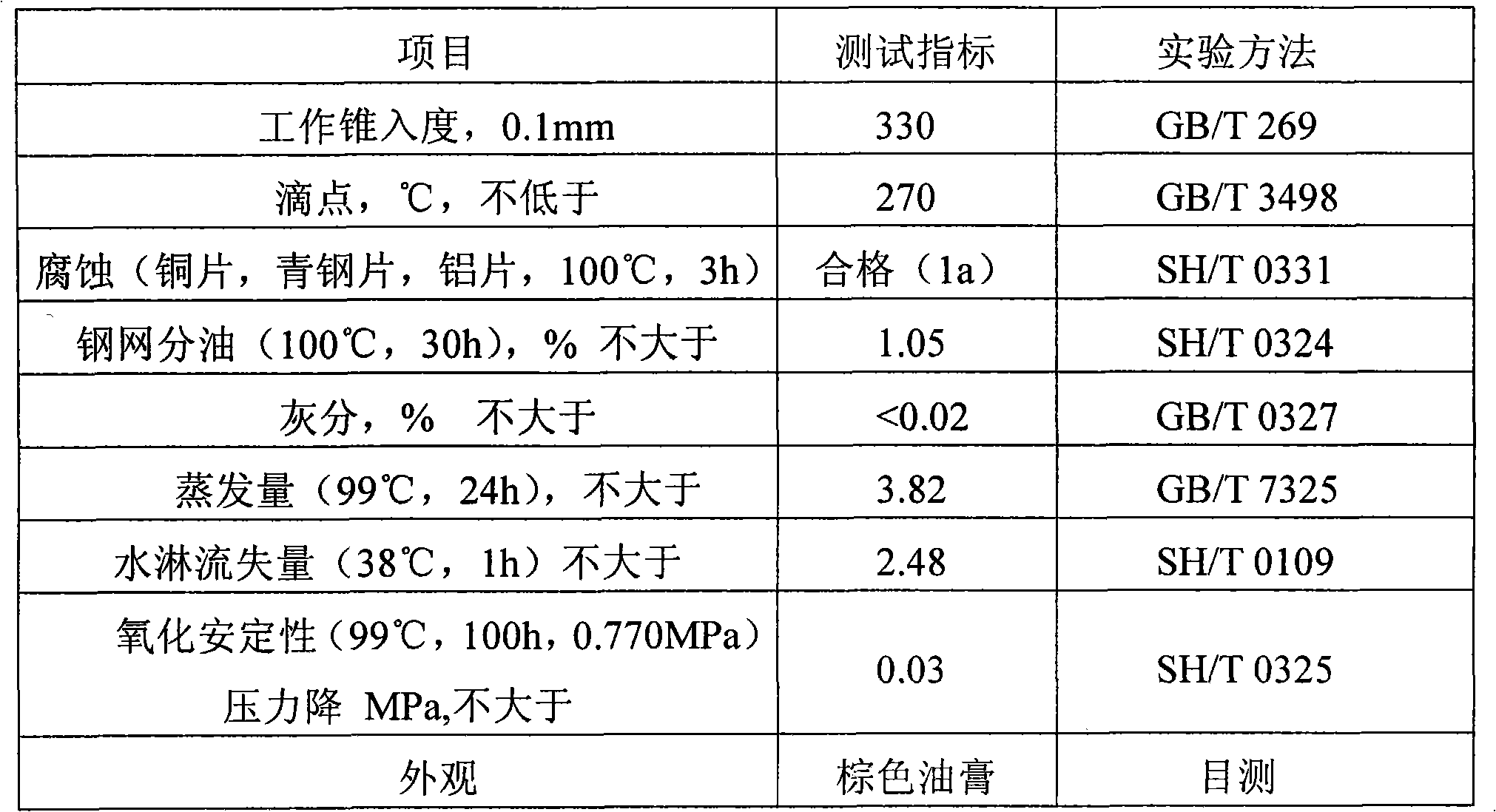

[0037] Embodiment 1, the preparation of the urea base grease that is made up of grease base oil and urea base thickener

[0038] Add 4.44g of octadecylamine and 1.76g of p-toluidine to 21g of furfural refined oil of naphthenic crude oil (viscosity of 7.92cst at 100°C), and raise the temperature to 90°C to completely dissolve and disperse the organic amine to obtain the organic amine- Oil. Add 2.42g of toluene-2,4-diisocyanate (TDI) to 21g of furfural refined oil of the same naphthenic crude oil, heat and stir evenly, quickly add to the organic amine-oil, fully stir and raise the temperature to 90°C to make the organic amine Reacts completely with TDI. After the reaction was complete, 3-8 mL of water was added to remove excess TDI in the system. Raise the temperature of the system to 160-180°C for dehydration, then raise the temperature to 210-230°C for puffing, and finally grind and cool to obtain urea-based grease composed of furfural refined oil of naphthenic crude oil and...

Embodiment 2

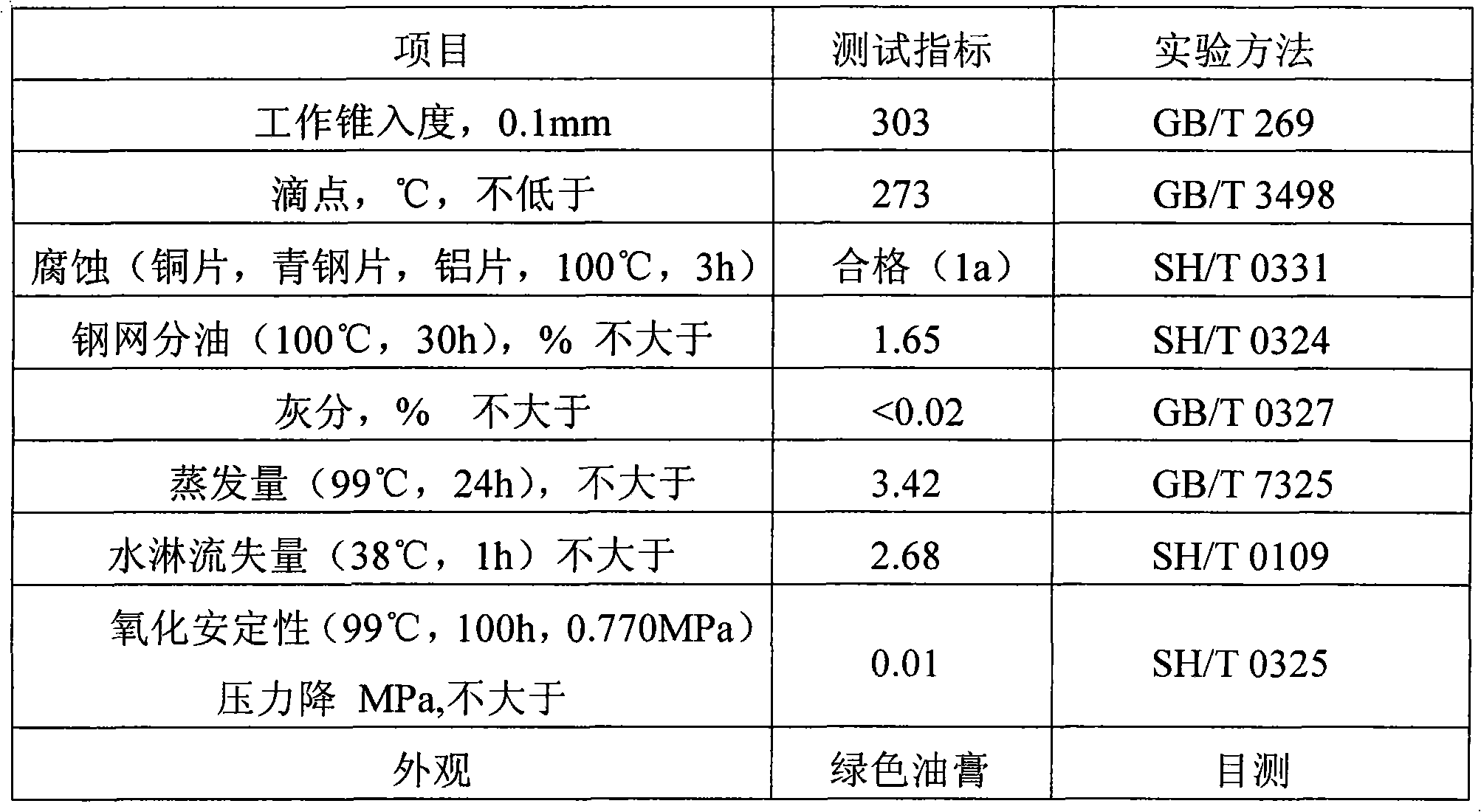

[0039] Embodiment 2, preparation of the urea-based grease composition composed of grease base oil, urea-based thickener and antioxidant

[0040]Add 15.56g of octadecylamine and 6.18g of p-toluidine to 84g of furfural refined oil of naphthenic crude oil (viscosity of 7.92cst at 100°C), and raise the temperature to 50°C to completely dissolve the organic amine and disperse it evenly. Add 10.26g of TDI to 64g of furfural refined oil of the same naphthenic crude oil, heat and stir evenly, then quickly add to the organic amine-oil, fully stir and raise the temperature to 80°C to completely react the organic amine and TDI. After the reaction is complete, excess water is added. Raise the temperature of the system to 170°C for dehydration, then raise the temperature to 230°C for puffing, cool down to 110°C, add furfural refined oil of 20g of naphthenic crude oil containing 1.20g of 4,4'-diisooctyldiphenylamine In the system, the urea-based grease composed of furfural refined oil of n...

Embodiment 3

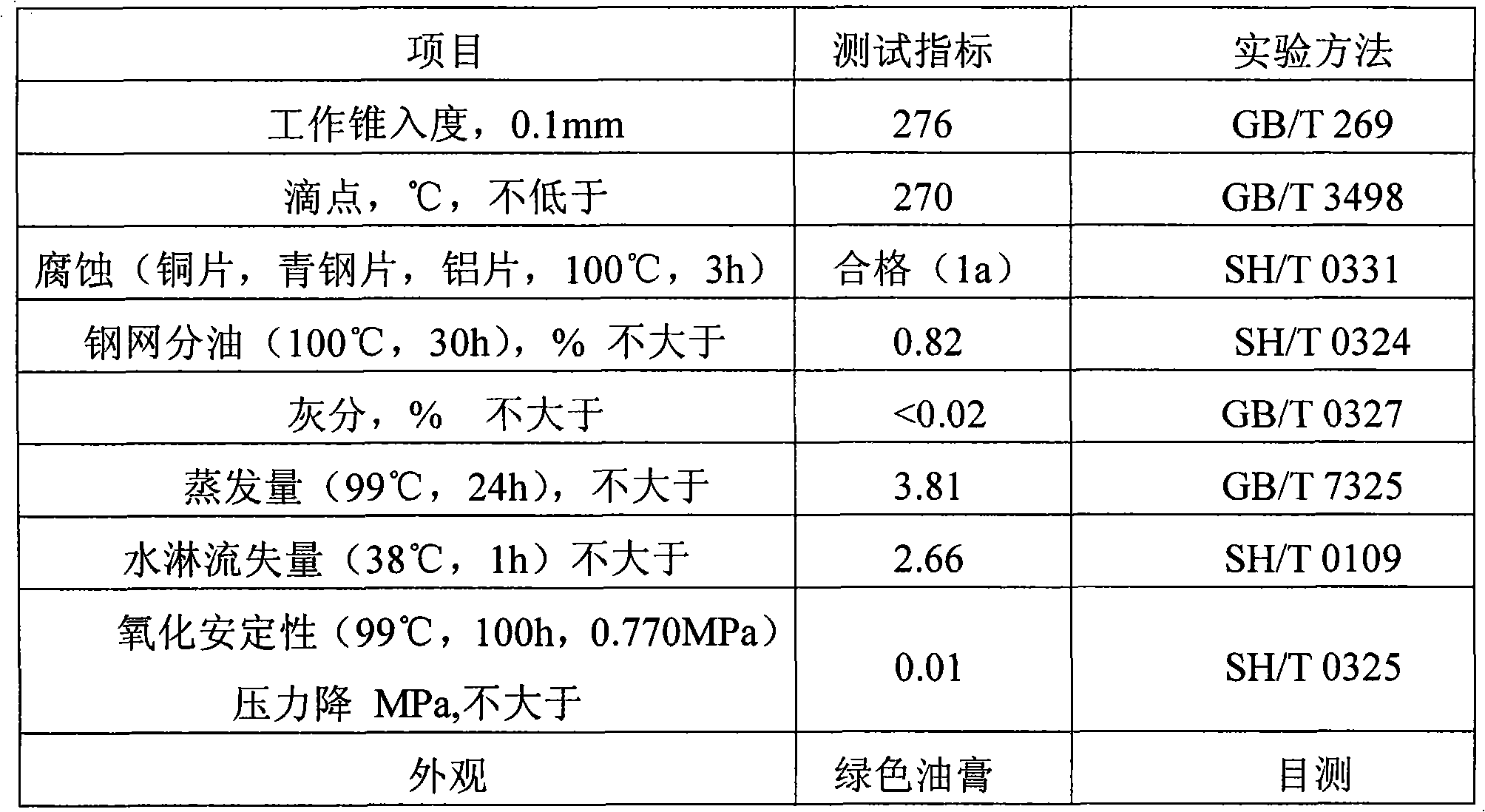

[0041] Embodiment 3, the preparation of the urea base grease that is made up of grease base oil, urea base thickener, antioxidant and pigment

[0042] Add 15.56g of octadecylamine and 6.18g of p-toluidine to 84g of furfural refined oil of naphthenic crude oil (viscosity at 100°C: 7.92cst), and raise the temperature to 90°C to completely dissolve the organic amine and disperse it evenly. Add 10.26g of TDI to 64g of furfural refined oil of the same naphthenic crude oil, heat and stir evenly, then quickly add to the organic amine-oil, fully stir and raise the temperature to 100°C to completely react the organic amine and TDI. After the reaction is complete, excess water is added. Raise the temperature of the system to 150°C for dehydration, then raise the temperature to 220°C for puffing, cool down to 100°C, and add 20g of naphthene containing 1.20g of 4,4'-diisooctyldiphenylamine and 1.00g of naphthol green B The furfural refined oil of base crude oil is added into the system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com