Lithium-ion secondary battery and manufacturing method thereof

A secondary battery and lithium ion technology, which is applied in secondary battery, electrolyte storage battery manufacturing, battery electrodes, etc., can solve the problems of high production cost, limited selection and application of battery materials, etc., and achieve the effect of excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

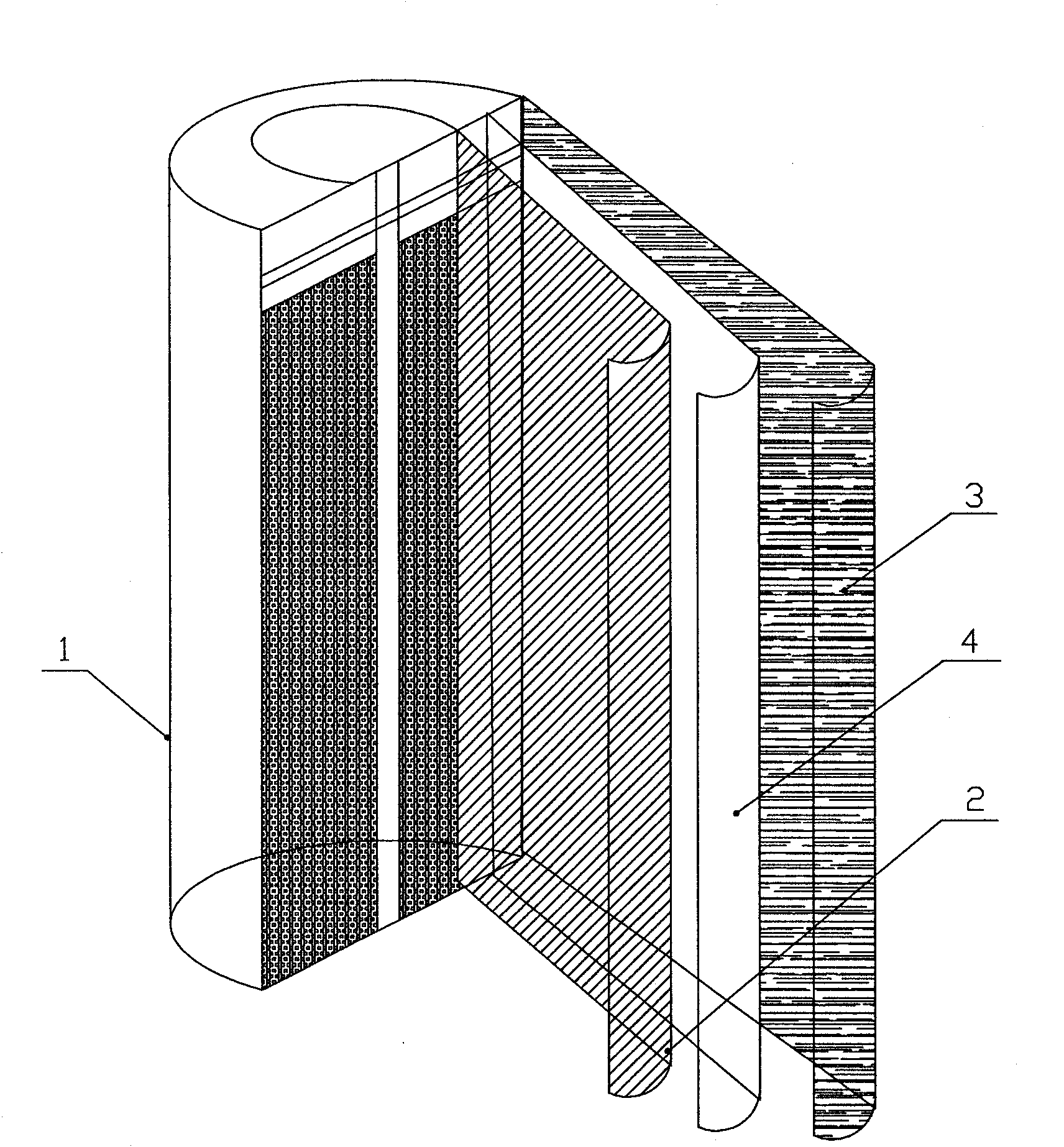

[0032] The lithium-ion secondary battery of the present invention comprises a positive electrode material 2 coated in a metal casing 1, a negative electrode material 3, a diaphragm 4 arranged between the positive electrode material 2 and the negative electrode material 3, and a filling therein. Electrolyte, the positive electrode material 2 is made by mixing nickel-cobalt-manganese ternary material and lithium manganate material in parts by weight of 1-9:9-1 (preferably 2:8); the negative electrode material 3 is graphite powder; The electrolyte is formed by mixing ethylene carbonate (EC), dimethyl carbonate (DMC), and ethyl methyl carbonate (EMC) in a volume ratio of 1:1:1; the diaphragm 4 is porous polypropylene (PP) or polyethylene (PE).

[0033] The electrolyte salt in the electrolyte can be lithium iodide (LiI), lithium perchlorate (LiCIO 4 ), the electrolyte solvent can be cyclic esters such as ethylene carbonate (EC), propylene carbonate (PC), chain esters such as dimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com