Non-magnetic metal ceramic mould and preparation method thereof

A metal ceramic and mold technology, applied in the field of metal ceramic materials, can solve the problems of insufficient wear resistance, low performance of non-magnetic hard alloy molds, etc., and achieve the effects of improving strength, good promotion and application prospects, and strong high temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

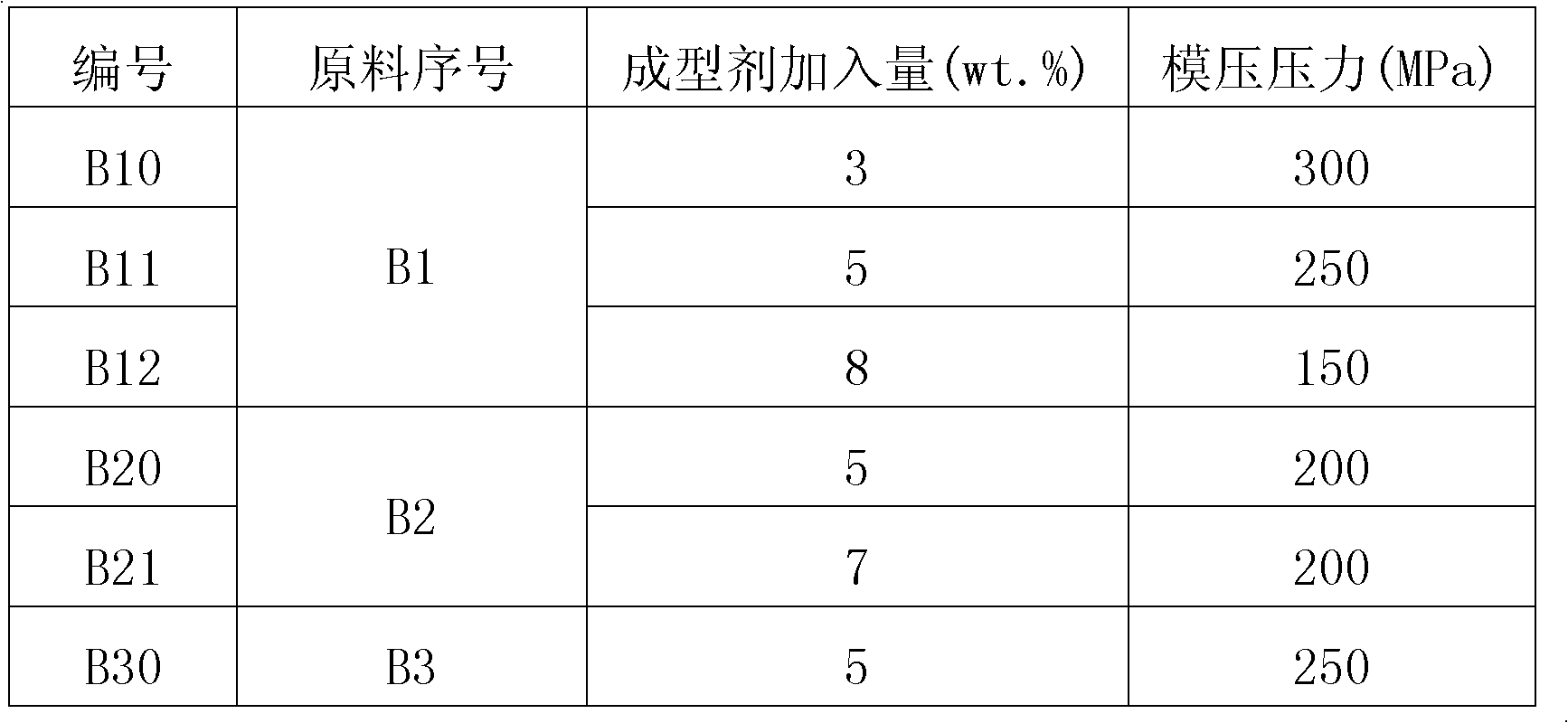

[0017] 1. Pre-solid solution treatment: Mix Ni powder, W powder, Cr powder and Mo powder, and the weight ratio of each component is: Ni-22, W-16, Cr-6, Mo-6, and prepare 6 groups of equal amounts The raw material powders were put into ball milling tanks and carried out dry milling on a planetary ball mill. According to the specific process parameters shown in Table 1, a total of 6 groups of Ni-W-Cr corresponding to A1, A2, A3, A4, A5 and A6 were obtained. - Mo pre-solid solution powder;

[0018] Table 1 Binder phase pre-solid solution process

[0019] Numbering

[0020] A6

[0021] 2. Raw material mixing: the obtained A1, A2, A3, A4, A5, A6 total 6 groups of Ni-W-Cr-Mo pre-solid solution powders were respectively mixed with (W, Ti, Ta, Nb) (C, N) solid solution The powders are mixed, wherein the weight percentage of each component is: Ni-W-Cr-Mo pre-solid solution powder 50%, (W, Ti, Ta, Nb) (C, N) solid solution powder 50%; drop into the ball mill tank ...

Embodiment 2

[0034] 1. Pre-solution treatment: Mix Ni powder, W powder, Cr powder and Mo powder according to the proportions corresponding to the serial numbers 1, 2, 3, 4, 5, 6, and 7 in Table 5 to obtain the corresponding 7 groups The raw material powder is put into the ball mill tank and dry-milled on the planetary ball mill. According to the specific process parameters of the number A4 in Table 1, the corresponding P1, P2, P3, P4, P5, P6 and P7 are obtained. Group Ni-W-Cr-Mo pre-solid solution powder;

[0035] Table 5 Composition of non-magnetic cermets

[0036] sequence

[0037] 7

[0038] 2. Mixing of raw materials: P1, P2, P3, P4, P5, P6 and P7 a total of 7 groups of Ni-W-Cr-Mo pre-solid solution powder corresponding to the serial numbers 1, 2, 3, 4, Mix the (W, Ti, Ta, Nb) (C, N) solid solution powders of 5, 6, and 7, put them into a ball mill tank and perform wet milling on a planetary ball mill with a ball-to-material ratio of 7:1 and a speed of 180rpm , th...

Embodiment 3

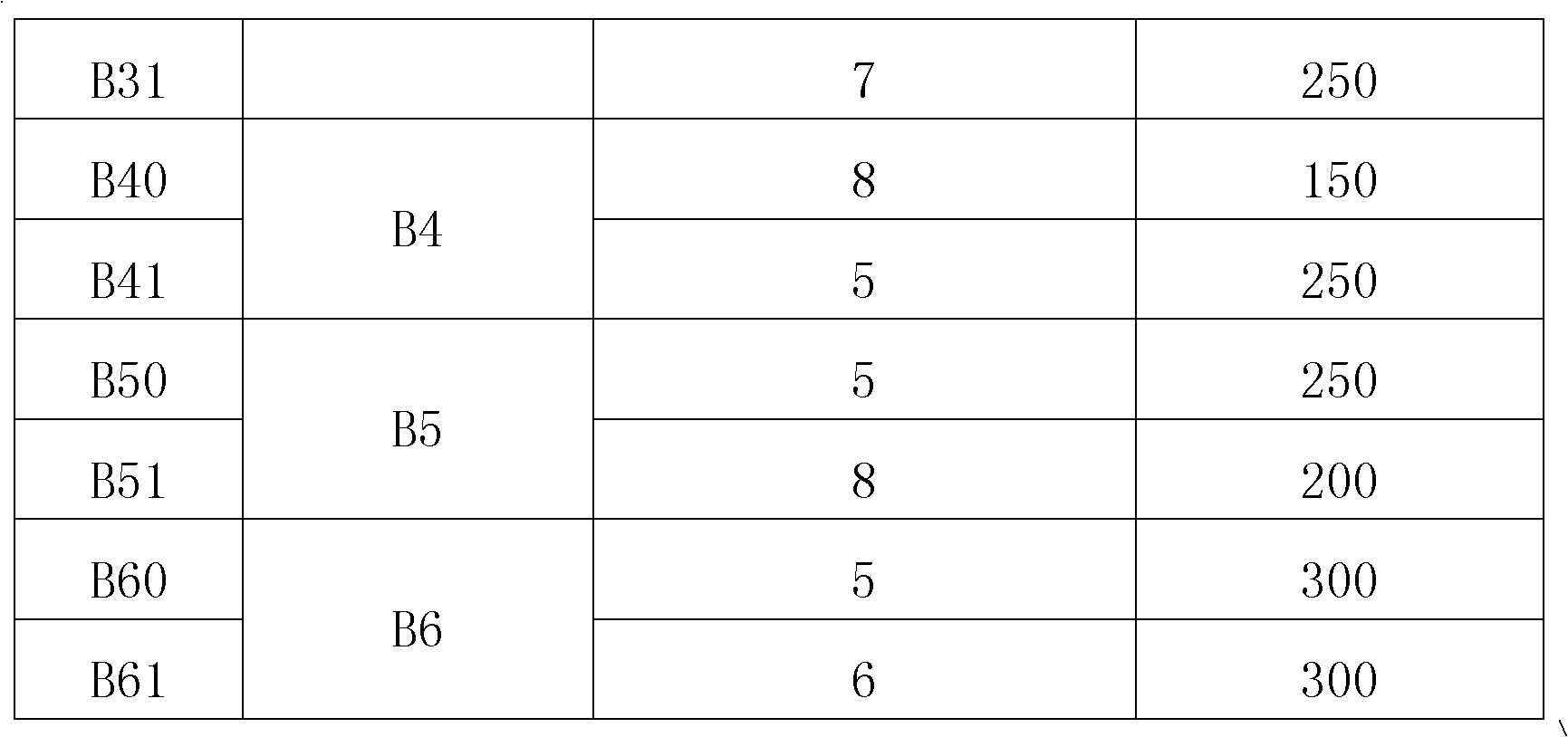

[0049] 1. Pre-solid solution treatment: mix Ni powder, W powder, Cr powder and Mo powder according to the ratio of No. 4 in Table 5, and put them into a ball mill tank for dry grinding on a planetary ball mill, according to the number in Table 1 The concrete process parameter of A3, obtains Ni-W-Cr-Mo pre-solid solution powder;

[0050] 2. Raw material mixing: mix the obtained Ni-W-Cr-Mo pre-solid solution powder according to the weight percentage of No. 4 in Table 5 and (W, Ti, Ta, Nb) (C, N) solid solution powder, and put it into the ball mill Carry out wet grinding on the planetary ball mill in the tank, the ball-to-material ratio is 6:1, the rotating speed is 200rpm, and the time is 40 hours to obtain the mixed raw material;

[0051] 3. Compression molding: add 5% molding agent to the mixed raw materials, and then compression molding to obtain a compact, the molding pressure is 250MPa;

[0052] 4. Degreasing: Degrease the green compact by using a vacuum sintering furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com